Have a question for you, is it normal to find 2-4% d8 inside of my D9 litres, they come up 90.8% d9 & then 2% d8 some 4% d8 when lab tested, is there another process that can remove d8 or is this something they are adding as a cut?

@Roguelab

Sounds like your oil was color remediated at some point. Sometimes a bit of d8 is formed during the process.

what exactly does that mean & is that bad?

Means they made the oil less dark and more shiny & gold/clear. Likely through a combination of pH change and achromatizing clays.

It’s pretty standard practice for almost all consumable plant oils (cooking oils, food oils, whatever).

So no, not bad, not bad for you.

It seems like a spinning band might do a better job right?

Only slightly I assume and still not enough to have clear cut fraqtions

Ever since the shoulder Thc-D9 has been identified I am more inclined to believe my previous statement that it can be done has any valeu

At the time I was running this I to had a lab claiming ND d9 while there was still plenty

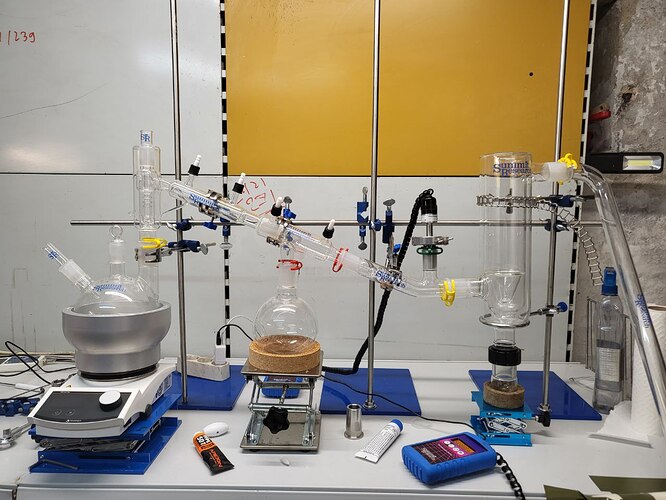

could you guys advise how to use SPD king’s 2l (summit research) setup with E28 pump, poly cooler and straight arms. Haven’t used my unit for 1 year and got all together today and had issues with Apiezon 500 lube that should hold 250 C and it started to melt at 200 and contaminated my flask due to poor quality joints used by summit. Have sent them an email just now as well, want to know why 2 way splitter jacketed female never fitted to male head joint(they had 2mm gap, basically female joint was too small and never had proper fit) plus while applying lube and rotating you can always feel off centred scratching unless you put too much of a lube that causes even bigger gaps in the joints (anyone had those issues?) while used Chinese setup before I had custom replaced all of the joints by a friend glass blower who put German high quality joints instead and never had any issues with leaking lube that resulted contaminating whole batch.

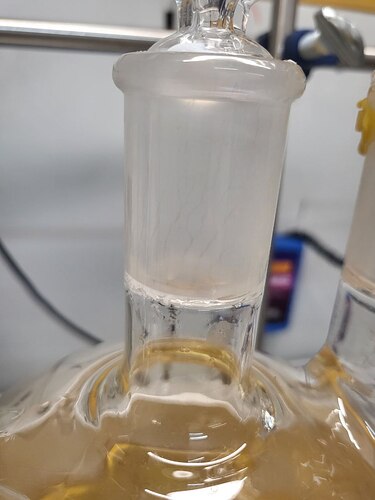

Also result came out slightly pink, not red, pink=\ used to have clear one. Also had 40-50 microns vacuum only due to micro leaks due to air escaping between joints washing out the lube(some had 1.5-2mm gaps in lower part where material bubbles by nature of distillation.

Used thermowell with 4 disks on it to have better separation but head temps never rose until had 200C + temps at mantle. I use Heidolf PIC controlled heater\stirrer with aluminum half sphere block on top of it to ensure proper heating with precision and no hot spots.

Please help, I am separating chemically converted CBD to THC and trying to increase d9 potency(best I’ve had was 60% D9 and 40% D8(lab tested).

Is there any way to do it right even with those faulty glass to avoid lube contamination and use of current setup?

pls find attached pics for your consideration.

p.s. my colleague placed plastic clamp instead of steel one - it melted, but never melted before since temps never rose that high and back pressure NEVER pushed our from the inside nor washed the lube.

Switched to 300C lube lab grade instead of using this Apiezon 250C(bs it melted at 200) overpriced sht.

Also first fraction that started to separate was around 170C at the top of the head but mantle was around 230=\ and resulting dirty was pink=\ always came out clear while used properly sealed china glass with replaced joints but never pink. Vac was at 40 microns next to pump reading and 50-60 after the splitter. Condenser was at 55C along with jacketed Y splitter using parallel condenser and rpm at 250 then ramped up to 300. I always measure temp of that aluminum block instead of oil.

Regards,

@Roguelab - please help Guru

I am baffled by hearing the faulty glassware coming from summit research and pretty sure

Eliot will solve it asap

As for temperatures something is wrong

Or the vacuum meter is faulty or the pump is

Clogged and not sucking as supposed

But the main message I have is

You won’t be able to split your thc D9 from your thc D8 in a % that makes sense all the effort you are putting in with spd

Also when you state

Mantel temp 230 first fraqtion 170

This is clearly a case of a cold head

Insulate your head with aluminium foil or with heat resistant rope or fiberglass cloth

You ca use a tefflon sleeve for the jiont at the bf or for all joints

It could work out more cost effective than the very special lube and less hassle lubing and it ca close the leak where it still scratches.

I kow that issue from cheap glass its fromm differet sources.

You can smear a thick coatig of lue aroud the edge for a temporary fix.

update. was running with less lube - still a leak - vac around 110 after Y split and 15 at the pump.

temps - did 20-30 C increases - flow started at 140 C in the head, foil helped to speed up the process. flask was 180, tried to continue increase it increase flow(as summit started about their setup), but always had super slow flow same I’ve had with china glass set. had recorded a short video, will upload it tomorrow since on the road now without constant internet.

flow was the same with 1 difference - it moved all the way to condenser with wave like pattern, never seen fumes moving like I used to while working with BHO, my goal now is to remove unwanted smells and odors and colors form chemically converted CBD to THC(d8+d9), it turned out slightly pink in color but you can call it transparent. anyone had it before? never had that pink tint=\

played with temps increasing flask form 180 to 240 and head was 140-180 and same flow, even slowed down at about 160.

my colleagues couldn’t run Polyscience chiller this time and used water in the conducer that to my understanding was main issue due to poor water heat capacity and conductivity(please correct me if I am wrong, cause used to heat transfer liquid all the time, had to improvise with a tea boiler and adding cold water to keep condenser at 40-45 C) does that plays major role of efficiency and flow rate for the head?

please mind I am only dealing with CBD iso converted to THC, not full spec extract.

most of the smell was just condensed in the cold trap but still some was inside the solution

@The710eXecuTivE - thx for the hint, do they come in different sizes or just overlay and fit in between the joint? would love to get rid of lube completely.

could you guys advise on the temps for best flow in my conditions?

also question about vac - maybe flow rate decreased due to micro leaks around main flask’s joints (110 microns is too much for E28, never had more than 20-30), decided just keep running at slower rates than to disassemble and restart, had full vac at dry run though), pump has new Inline 19 oil and it looks super fresh, don’t think it needs to be replaces unless having 24-48h of work time, am I right or wrong here? pump eats 2l of it, have a spare 5 gallons, just asking how often should it be replaced)

thank you all for support. hope we will find solution to remove those smells, colors and odors in more efficient and time consuming way.

@Roguelab - thank you so much for tinfoil tip - it helped but flow rate still around china setup like 250ml per hour=\

best flow I’ve had with this run and weird flow at the condenser

I also noticed another oily crap in cbd isolate with a lower boiling point: Looking to buy isolate - #21 by The710eXecuTivE

To avoid smelly and overall unconsumable and toxic conversion you have to use trustworhy cbd that hasn’t been denatured. This is the most important advice regarding conversions anyone can give. I haven’t found any yet and seems i have to make the isolate. And then still recrystalize the cbd to get the yellow oxidized yuck out. Also it is better to not distill to the last drop but leave a little puddle in the boiling flask, I think a lot of unsavoury and yellow concentrates there, but maybe not necessary with both clean and recrystalized cbd.

The purple could be from leftover bicarbonate or whatever you used that interacts with leftover unreacted cbd like a beam test but I have no idea. Maybe you used too much and didn’t wash and dry properly. May I ask which conversion process you do?

I had a little purple tinge sometimes only in high d9 conversions made with very dilute hcl according to Adams, which is actually not a good way to do it but a very accessible route to mainly d9. But it makes many other things too in traces and a lot of ethoxy-hhc. But no purple in what ended up as mostly d8, so it could be d9 specific.

You should smear lube around the rim where the hole is that leaks.

@Roguelab is right. You’re not gonna separate d8 and d9 with an spd. You can try, I sure did, but it’s not gonna work.

The Pink comes from Not correct ph.

The smell you have is from inpropper quench .

The smell is from shitty cbd, or from distilling way too hot because of leak, but it doesn’t sound like it in his case. Or from distilling with acid or base still left in the solution to make random isomer soup, but also doesn’t sound like it if he has 60:40 d9:d8. Do you mean that with improper quench?

I had this issue with the smell also Running My reaction with alcl3 and i solve it with a diffrent quench.

Your quench is next level ![]()

No seriously I understand you should not give it to the community yust like that

For it s a holy grail you cracked no quench

Comes close to yours ![]()

![]()

what do you mean by “improper quench”? thx

could you please give a solution how to avoid it? thank you