Alright, it’s been a 4-5 month journey so far into this new world of cls chromatography and the associated medias. I run a pretty standard stack. Double coffee filter under my media, 5 micron paper under that, 2 micron sintered from Nate at the bottom. When I first started I was doing a 3 part mix of the 60a, alumina and t5, I had great results for maybe 20 runs. I’ll admit I was doing some pretty minimal cleaning but the sintered always “looked clean” so I would just keep on moving without any real cleaning procedure. Eventually clogs begin to occur, I also switched from getting my media from BVV to Xdepot around the same time, should be the same media right? Well anyways I began cleaning up the sintered disk, at the time ethanol and pressure seemed like a wise choice, I was able to get it clean but I did hear a distinct Pop! at one point when i was putting it under pressure, this is one of the many variables I am questioning that now led me to where I’m at… did I blow an area out around the side welds? Nothing seems visibly different so I assume it’s ok but I question if that pop created a gap on edge. So now back to the point of this post. No matter what I do I cannot keep the very fine sub micron particles from coming through into my product. I’ve tried the Celite 545 bed (which seemed to be the worst results so far regarding full blown contamination) I’ve tried stacking the media in every possible order that people have recommended with and without the Celite and still the problem persists. If I run straight t5 it seems to eliminate the problem but unfortunately it just does not pull color like the 60a gel does, I desperately want to run it and t5 as my go to media mix but I am unable to keep the fine toothpaste like sediment from entering my product and eventually clogging my filter. 4 months ago I was able to do this just fine but now I’m pulling my hair out trying to figure out how to run this media without contamination, I’ve tried pre washing the column with 5-6 lbs of solvent, when I recover I rarely see anything in the bottom, after cleaning and starting my run is when things start to get gnarly, another variable I’m questioning is the vapor loop, could the heat from the hot vapor somehow be pushing these ultra fine particles through? I never exceed 65ish lbs of pressure. Part of me wants to blame the media, part of me wants to blame the sintered disk, I completely understand that a 2 micron disk isn’t going to catch these sub micron particles but why was it not happening in the beginning? Who else is having these issues? I’m completely at a wall now regarding all this as I don’t want to put out products that are full of nasty crap. Let’s get down to brass tax on this because it’s a major problem and it has to be more than just me. Murphy’s sop is failing me, everyone’s tips and tricks are failing. Is anyone running the 0.2 micron sintered disks I’ve been hearing about?

You should definitely check the integrity of the crc filtration spools, and the edges of your sintered Disk as well, if you have found issues with channeling you can have failure within those areas due to a forceful flow, make sure the media’s you are getting are the proper micron diameter to be properly filtered. All of your media’s should have an easily available SDS sheet. Pushing too hard with your vapour assist can cause issues as well. I’ve found adding 5 micron mesh gaskets before my sintered disks has worked well for me.

It s not a sintered disk 0.2 um it s a firlter cartridge the plastic ones are good till 75 psi the stainless steel housing one a up to 150 psi

Search for Sanatary falanged filter cartridge And several brands will show

Your using a filter paper with a ring on top

of your disc?

2um will catch everything carbon chemistry carries by 10-fold. If it’s not doing so then the filter isn’t functioning properly. I encourage you to get a new filter plate from @Killa12345 and in the meantime use a stack of 4 filter stacks, from the top to bottom 10um, 5um, <2um, <2um. Have your powders sitting on top of the 10 um. If this is not working then you are not situating your filter papers adequately, and it would be foremost beneficial for you to address that.

what are you using for rings to hold your paper in? If you’re not getting an incredibly snug fit with the paper and the ring then it’ll blow by every time. Have you cleaned your lines that may have old powder in them from a blow by?

I’m using standard filter rings, I’m questioning if my papers were cut to small because they weren’t quite reaching the top side of the rings and maybe had a 2-3 mm lip or so against the wall in between the ring. They seemed secure tho so I had not questioned it. But I’m questioning everything now so, new paper should be here in the next couple days. The best paper I had here in the new lab were whatman #2s and I was under the impression they were smaller micron then they were but it looks at if they are 10 or larger

The paper is best over sized so that when you push your ring into your spool it creates a seal. I have the feeling you are getting channeling and now probably solven going between the ring and the spool.

What’s the code on the box? 1003-090?

Can’t remember who but someone does use this. Arbor fabricating supplies utah so i would go through them for faster shipping. They only have a 30psi rating based off what customers have used them at. They havent done there own tests

Yeah that filter paper is for sure a problem, Are you pressing the celite in with something? If not that’s undoubtedly a problem as well

I use celite on 11um filter paper and have never had a blow by. I use plenty of other filters to catch anything if it does get by. But the celite cake stops it all

Yea I have the sweet little tamper that n b Oler gave me. But I question if my retention at the top of media stack is securely holding as well. (Perf plate with a couple rings and like 5 coffee filters to make it really snug, it’s never out of place after the run so I assumed it was holding things in place)

Having the papers at slightly too small of diameter has to be part of the problem, they were all pre cut to that size when I moved into the lab and they appeared to fit nice so I never questioned it

Sounds like you got it, good luck dude!

Oh they are actually the advantec #2 looks like, but I was also using these whatman #1s (1001-150)

I believe @Curious_Roberto is using those

Those are 11um.

Well thank you everyone, I’ll have the 2.5um and the 8um coming in the mail this week as well as one of the Chinese 5um sintered to stick above Nate’s to hopefully test if I blew out the edges of that 2um disk. Hopefully just the proper micron paper will do the trick even. Fingers crossed.

I tried it, so my experience with them is not great, I’d go directly through their supplier if you can. They sent me the wrong pore size, I ordered a 1um and they sent a .5uk,and tbh, it came all scratched up and overall sloppy looking. Not a great experience, that being said, it worked, but with the pore size so small, it restricted my flow too much.

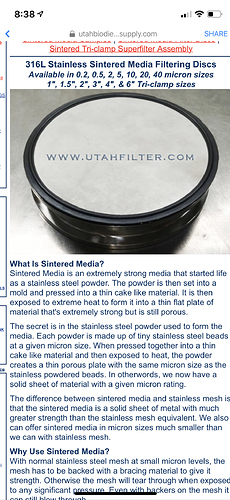

http://arborfab.com/SinteredMediaSuperFilters, order directly from these guys if you do, screw the middle guy. They’re cheaper from arbor too.

Looks like you got it figured out, but for anyone else, there’s the info!