They are probably welded and not swaged. And the tube sheet (the face of the condenser with the 19 holes) is then probably of thinner construction and won’t offer you much in the way of material to remove.

Yes tubes are welded to the tube sheet as well! Just need to find a decent nozzle for the spray job ![]()

![]()

what about putting a distribution tray above the tubes?

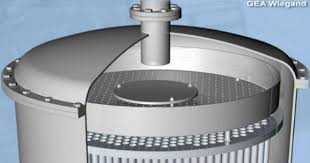

You could do raised tubes like this

Wanna make it for me ![]()

I was thinking of getting a raised tube price done like that think it’s possible?

Hi,

absolutely, we can get er done for sure.

Deleted wrong thread

deleted wrong thread

Congrats sir. Enjoy the sleepless nights and constantly dealing with shit! lol teasing of course! Best of luck to you and the famalam

How about spraying the solvent upwards at the head and letting it drip back down? Maybe use a piece of wire mesh to help distribute it further. Something like the water condensing and dripping down off the top of a Dutch oven whilst braising.

That’s super clever but would be hard to implement trying to get the nozzle to do 180

With enough pump pressure you can just spray it into a hemispherical plate. Otherwise, you could eliminate the center tube(s) and hook the feed up from the bottom (just use a bore-through fitting on the bottom vessel).

This won’t be using a pump but I like the idea of coming up the middle of the condenser if your condenser had raised tubes you could connect via compression fittings and it would be perfect

Now I am thinking of going with the spiral cone atomizer along with a raised tube plate above my evaporator. I am wondering though if this is necessary, the flow rate we are working with is very small, when compared to ethanol ffe and I am more then sure our evaporating surface is pretty far over sized so getting perfect distribution is not necessary so maybe the nozzle will do fine by it’s self.

Having the tubes extend past the sheet seems like a very popular way of ensuring distribution. Having read dozens of topics about this, I keep coming up with the question “why does this help distribution vs a flat timesheet?”. The heights of the tubes need to be very consistent and the timesheet very level in both axes, otherwise the lowest tubes will get overwhelmed. Wouldn’t a similar outcome be achieved if the timesheet was very flat (maybe turn flat on a lathe after welding if we get extreme)? Especially with close tube spacing. We just did some 5ksi shell and tube units with 57 1/4" tubes and they’re only like .110" between tubes. I know @Soxhlet and @future have a lot of experience in this topic so maybe they can use the correct crayons for me to understand.

My other thought is that while it’s not efficient to have tubes overrun (because as vapor blows it’s way back up you lose use of that surface area), if you were willing to accept the inefficiency you could run smaller tubes on the OD and get larger towards the ID. Using a nozzle that favors the OD, you would fully flood the outer tubes as the solvent flows inward. If the exchanger was long enough to boil everything on the larger tubes, the smaller tubes would never allow liquid solvent all the way through, so you would never overrun until the innermost tubes are overrun. Disclaimer: totally thought of this while typing so it might not make any sense at all.

Another note about tubes extending the tubeheet is that they are a proper bitch to weld. Especially when the tubesheet thickness is greater than the tube wall thickness (which is usually). Getting the electrode to not side-arc can be a pain because you are usually much closer to adjacent tubes than the root unless they are cut close to the sheet. The bigger issue is that usually you strike arc on the tubesheet and then enlargen the puddle to catch the top edge of the tube, which is much easier to melt than the side of the tube. Trying to do this with the side of the tube likely causes the tube to retreat like a Frenchman (as they say) if you’re not quick enough. It’s certainly not impossible, but what it means is that for any given tig skill, you can weld a thinner wall tube to the sheet if it doesn’t extend the sheet (which is pretty much always better with stainless).

Edit: the neverending battle against autocorrect

good luck pooling directly on your hot evaporator surface

That’s not very supportive ![]() I actually will not be pooling directly on it, it’s a small section of spool the will attach to the top and the plate will be mounted in that about .5 inches away so it will not be direct contact

I actually will not be pooling directly on it, it’s a small section of spool the will attach to the top and the plate will be mounted in that about .5 inches away so it will not be direct contact

My thought is that the raised tube plate would pool your oil in the upper section of the evaporator. Not all by any means, but some.

Ahh yes unfortunately that will be a issue, but I am still not sure a plate is even needed for this