Hey everyone, hope everyone is doing well during this challenging times.

After moving my active close loop away from consumables for heat exchange I realized I have much more power then what is needed to actually just condense the gas versus the current way I am implementing the chillers which is removing the massive amount of heat the pumps generate.

After seeing the restricted flow rate that comes out of a typical crc column it got me thinking, it would not be hard to evaporate and condense this small flow rate with the chillers I have handy.

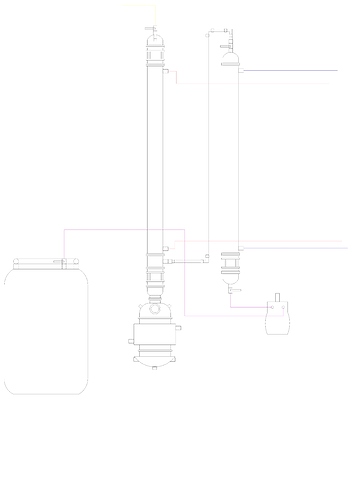

So on to my design, the top of the evaporator will use a mister to evenly disperse the solvent into a thin layer that can be evaporated easily, which will fall into a collection pot that will be removed to pour or dispensed out the bottom, vapor will pass through a tube to the condenser will be condensed then pumped by a TRS – 21 recovery pump to a recovery tank

My question is do we think this design will work and are there any design changes that are needed I can update the drawing as needed.

Condenser and evaporator design and size

Tube in shell 3x36 19 3/8ths tubes

Collection pot size: 6in

17 Likes

This is brilliant.

Worst case scenario it falls into the collection vessel and is recovered from there.

5 Likes

Exactly but I am more worried about it evaporating too soon and not making its way down the evaporator

@FicklePickle

4 Likes

This could be mitigated by not heating the evaporator as much or by how fast you push into it.

Definitely some r&d time to figure this out

4 Likes

Then increase your butane feed volume if it isn’t making it down, or reduce the temp of your thermal fluid in the jacket. You’ve got to balance that thermal transfer to your desired point…

I’ve been contemplating FFE butane stuff…i think it will be a bit of trial and error on dialing such a thing in…at least by my dumb ass. I’m looking at using a tube in sheet on the recovery side of things.

Need to get some seamless tubing ordered and get to playing.

6 Likes

Absolutely my condensers are baffled so if I felt spicy I could just reverse where the solvent feeds into the condenser

@TwistedStill

I am dooing this with a deplegmator

So my liquid butane enters the collection pot treu two filterdisks set at an angel to disperse the liquid then enter the 3" x 12" deplegmator

This way the solvent is fairly evenly

Seperate over all the deplegmator tubes the solvent boils off at 70% leaving the deplegmator wich is set at 70C I can keep a constant pressure of 50 psi recovery unit running in the collection pot wich is set at

50C in the jacket

And thus optimizing my recovery unit with a high pressure intake

14 Likes

You were able to get 70% of solvent evap with only 3x12? 70c is really high though so I wonder if we increase residency time if we could do a temp drop

Are you planning to run crude with this? I was hoping to run smokable quality extracts with it.

2 Likes

Smokable shatter

My solvent starts from a collection pot thou wich is pressurized at 90psi so I don t get back pressure from the second collection pot that’s heated

16 Likes

Fucking @Roguelab for the win

7 Likes

So rogue you you loop looks like this solvent from columns—> into collection pot pressure set to 90psi —> through heat exchanger set at 70c—> collection pot set at 50c —> recovery unit back too recovery tank yeah?

So you’re just using the evaporator to produce large amount of vapor so it keeps the recovery unit well fed correct?

3 Likes

Yes that’s it

I developed this method for i work with a large system and the jacket and internal coil can t exchange the heat neccesary so by heating at the moment of entry I am able to get the vapor developed that I need

The temp of 70 C seems high but the

Vaporization extracts heat so the cannabinoids don t get that heat for real

And for a very short. Period only not affecting the shatter consistency of my end product

7 Likes

If anything the the heat is slightly helping with the consistency

@Roguelab

3 Likes

Alright guys! Wish me luck I am going to order the prices that are missing from what I have and going to give this a shot! Hopefully all the stores ship…

5 Likes

What’s the lead time on getting a small job done by you right now… need a 1/4 fnpt welded on the inside of a hemispheric cap…

Im in the hospital with my wife, and newborn, and am deemed essential at work but will be on quarantine because my wife basically had major abdominal surgery. I do have acess to my TIG machine, but things are pretty busy…

If you could ship it to me, give me a few days to get to it, then ship it back, I could probably do it. Surely there is someone local to you still striking arcs?

1 Like

I mean I could find someone local but you’re forum Welder lol if it’s a hassle don’t worry dude you got life going on

1 Like

Hope the wife is okay!

@TwistedStill

1 Like

Oh she is quite well. Had a c section because babies heart rate didn’t like pushing. Everyone is healthy and happy.

I appreciate you reaching out though.

11 Likes