One is half the price then the other. Can I get away with useing the cheaper one or do I gotta use the more expensive…

I guess technically the HT would get you to 160C and possibly the 177C it’s “rated” for. Which will most likely get the job done on your rig. If you’ve got enough vac, you might even find you’re running closer to 120C, in which case either would work. I’d talk to the folks at Dynalene to get a feel for how running so close to the rated limit will affect fluid life.

the 150C on the SF seems to be pushing it just a hair.

@Soxhlet might have experience in layering N2 over an open bath to squeeze more temp out of your fluid. Or that might be a terrible idea. Not qualified ![]()

or see how much MultiTherm OG is MultiTherm OG-1 Oxidation Resistant Heat Transfer Fluid for Open-Loop System

it’s rated to 290C in an open config…which seems a little high, given a flash point of 235C and a fire point of 271C, but hey, its got OG in the name, so it must be the right stuff…

Has anyone tried a motor oil designed for diesels?

as in https://www.amazon.com/Delo-5G-15W40-Each-400-SDE-15W40/dp/B073JSB59R

again, it may not be a brilliant idea. just spit-balling.

About the safegaurd I added. Going back to the chart I posted earlier. If a 30% ethylene glycol / purified water mixture was suggested for the temperature I am working with, I would do a 40% mix to give myself a little headroom to play with my temps.

Nice for the chillers in the rotos that’s perfect.

Is that an open bath?

China brand it’s 15l open bath for the wf

Any idea if using a pure methanol solution in a chiller is ok? For example polysci durachill -10. I have plenty of methanol and would like to boost the chiller with dry ice or ln2 to run colder but have never used anything but pg/water.

Bump ![]()

Anyone run cheap 100cst silicone oil? Well not cheap but cheaper than dynalene

Soxhlet-

Your mention on heat-exchangers speaks to me!

Looking for a energy efficient & speedy way to bring our cryo-ethanol up to near room temperature, prior to rotovape, what vendors may you recommend?

Grateful for all the insights you offer the community. Much thanks!

Atom

Heres a wild ass idea, run your cryo etoh through the condenser of your rotovap, then through a preheat tube in the rotobath before injectin it into the rotovap.

Bloody brilliant, mate!

I’ve been reading studies the last day or two describing the difference between propylene and ethylene glycol. Ethylene has better heat transfer characteristics but it appears to degrade faster

Industrial solution

ElectroSteam https://www.electrosteam.com/

Simply replace water input with ethanol and reduce temp set point to something south of BP (78C) of ethanol.

Home lab solution

Common residential pool plate type brazed heat exchanger.

https://www.google.com/aclk?sa=L&ai=DChcSEwjRx_iMj4XgAhUJDmkKHcrEAGoYABAIGgJpcQ&sig=AOD64_05hCFFhWAhRa-BWMME_xiW6fDOrA&ctype=5&q=&ved=0ahUKEwiakfCMj4XgAhWbnoMKHWdqADMQ9aACCDU&adurl=

Residential hot water heater on the primary side, ethanol solution on the other side, couple of re-circ pumps. Inexpensive set-up and depending on your knowledge of controls, pumps and the like, very simple set-up.

Hi, All!!

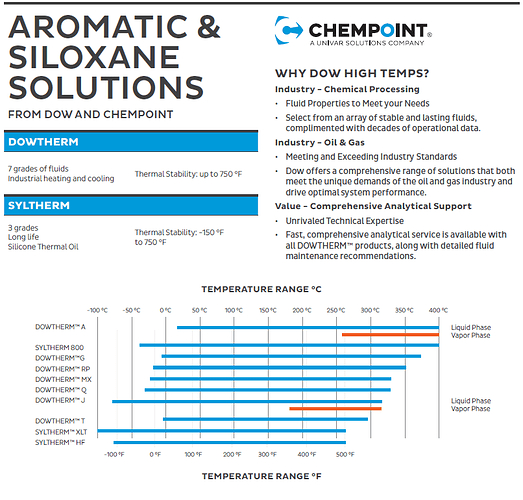

ChemPoint has many chemistries used in the Cannabis/Hemp Industry~

We stock Dow Syltherm XLT in California and Chicago for your condensers and chillers.

We stock Dowfrost inhinited Glycol in warehouses across the country.

We will provide you technical data and have a tech onsite for your questions: Nitro Jackets? Volume Variations? Which grade do I need for the best protection and temperature requirements?

Anything Heat Transfer Fluid related - we know the answer ![]()

Give me a call or email if you need pricing or have questions. Thanks for the opportunity to partner with you~

Rhonda Valentine (425) 372-9043

rhonda.valentine@chempoint.com

China chiller and cheap Meijer coolant go hand in hand. I’m in the same boat - not too worried about my China chiller.

I’m confused, so you designed the WFE but you have no experience with WFE or a SPD?

As someone with experience using Dowtherm products (T-66 and VP-1), I don’t recommend them to anyone without a strong industrial safety background.

Edit: I felt this was worth necroing in case someone else comes across this topic while researching. T-66 and VP-1 can cause severe injury if improperly handled.