Estokha is correct. That is why we recommend Dow Syltherm XLT for closed system. Not open.

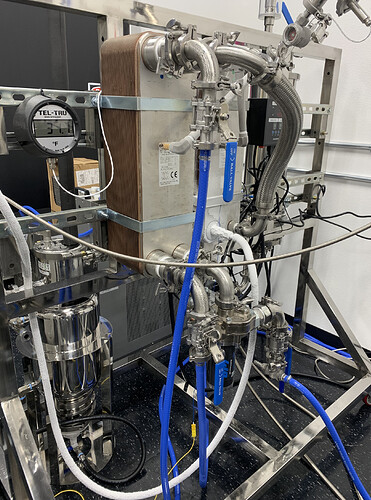

So I took some info from this thread and ordered a couple brazen plates. We had a spare chiller so the idea was to build a dual stage chiller, the first plate (60 plate) doing the heavy lifting using the chiller to keep temps at 0C, the second stage (20 plate) has a direct connection to LN2 with vents sitting directly on top of both brazen plates for added cooling to bring it down to our desired temp of -40C.

Our Biofrost 80 fluid froze up instantly. We thought it was because it was diluted with water we think. So we went with 100% Ethanol and that allowed us to hit the second plate for extended periods bringing our temps down to -40 pretty quickly. The problem was the fluid heats back up almost instantly to 0C. This required a ton of LN2.

Does anyone have any ideas on how to better use the LN2? or the fluid running through the plates? Can we simply add DI water to the ETH to make it more efficient? Should we use other fluid?

Thanks!

1 Word… Insulation… I’m not sure about the fluid TBH, however you have absolutely NO insulation on anything… I don’t know if this is right, or wrong, however I would try to do a good job insulating your LN2 tank (or whatever your pouring you LN2 into), try insulating the lines (even with just cheapo insulation).

These are just random off the top of my head things I see by looking at your picture, and using my own rationale for remedies.

I’m not one of the Masters though, so take what I say with a grain of salt.

But I did stay at a Holiday Inn Express last night, so there’s that…

Agreed, we typically do the insulation last. Just wanted to nail the concept and idea first. We typically use the hose insulation from HD. And we have 1" thick adhesive back insulation from McMaster that works well for the Brazen plate face and rear.

Beautiful Plates though!!! To say I’m jealous would be an understatement! Sorry, just trying to help with my limited knowledge/understanding. I wish I had invested some time reading more into chillers, and such. But I’m just 1 guy, doing things at home, so the thought of actually purchasing a chiller for in process work has been far out in left field for me!

How do people get colors in the condenser coils on rotovap I see greens and reds. I wanna do purple any tips helps thnx!

Food coloring

Dow therm is pink. Dow frost is yellow. You can food color them as well:)

The oil cooler thermostat in a MP series Mack opens around 285F.

Drain interval is 25,000 miles. Your mileage may very.