If they have access to non contact cooling water it’s a feasible option. This usually returns the process water to storm and is from a non-potable source. In our case we have access but still use a cooling tower. Our NCCW is like 1/500th the price of city water. It does require permitting however

Run straight n tane and go for a -20 chiller for a fraction of the price. You’ll never know the difference unless you don’t have sufficient heat to boil it quickly

It’s for live resin. Do you fell that -40 might be better?

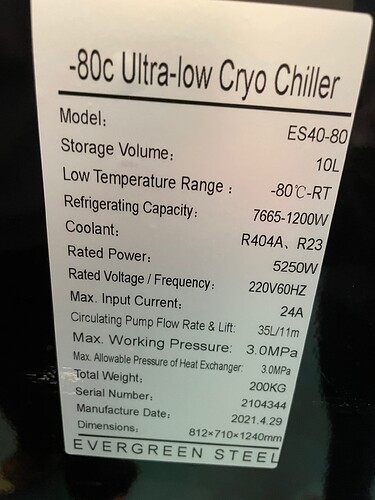

What is the kw rating at -60?

I don’t have that breakdown unfortunately. Just the max and min on the sticker. It beats the Huber min KW rating at -80 by 2x

No. -20 is all you need for extraction temps. -80 solvent for extraction will take forever to soak all the oil out of the biomass. You can certainly go with a -80 but it’s really only worth it for running propane blends. Since it’s a -80 it’ll burn out quicker and you’ll deal with downtime and repair costs more frequently than running straight butane with a -20 or -40 chiller.

Those Chinese ultra low chillers are know for defying physics

If the chiller is designed to run at -80 you shouldn’t “burn out” quicker than another chiller.

That’s silly

Oh so everything works perfectly the way it’s designed? Even in this industry? Don’t be silly. -80 blow through compressors way faster because they work a lot harder.

HAHA so true, it’s hit and miss with them though, some last forever some die in a week

Propane is usually ran warmer, unless you are wanting a terp strip. And I would never run live resin at -20c. Oh your god no, please don’t recommend this.

Not mine.

Lol why wouldn’t you run live at -20? You need to be below freezing to keep the ice from melting away and cold enough to not extract lipids but if your column is cold, material is cold, solvent is -20 I’ve seen zero issues with running live resin at those temps.

I’ve done more than enough extractions at various temps to know that I make a far better product than anyone, anyone extracting at only -20. Just being below freezing isn’t the only thing about running cold.

But, we are also in different lanes. The end product quality we are striving for is far different.

-20 is fatty as fuck. Ewe

Like I said, I ran ff for over a year with -20 solvent and didn’t have issues with lipids, potency or consistency of end product I get it, you bought an expensive chiller

I’d use dry ice instead if I had to, or even a cheaper/inexpensive chiller. But I wouldn’t ever sacrifice my quality to extract at -20.I make a far better product than that, I think we can agree. If you make products of the same quality, you wouldn’t be selling equipment.

Lol I designed that machine as a side project. I run every day dude and have for 8 years

Well, except weekends, holidays and when I feel like taking the family on a vacation.

And honestly I’ve never seen your products and don’t really care. I’ve also extracted with dry ice, with -80 chillers, -40 chillers and even -30 chillers and in my experience, -20 is fine as long as your columns and material is cold as well. There’s a big difference between extracting with solvent that’s at -20 and doing an actual -20 extraction.