In todays episode of, fucking with the nitrogen generator…

When the day started, my setup was like this:

Frank the tank loud MOFO air compressor → refrigerated air dryer → 3 stage air filter/dryer + regulator → zero air generator → nitrogen generator → storage tanks

I end up removing the regulator from my 3 stage fixture entirely, primarily because I did not have the appropriate 1/2” NPT to push connect fittings (somehow i have 6mm and not 1/4 OD - thanks amazon?).

So, with that being the case, the theory i wanted to this this morning was regulating the output of the generator on the n2 output side; my thought was, the manual specified running it at less than full capacity and i thought i could do it this way.

Well, 500ml/min is apparently just too low for a regular air compressor regulator, with that discovery i removed it all from the setup and ended up now with this:

Harbor freight ultra quiet air compressor → refrigerated air dryer → zero air generator → nitrogen generator → storage tanks.

Using the PSI control at the air compressor i am semi-able to control the output, maybe?

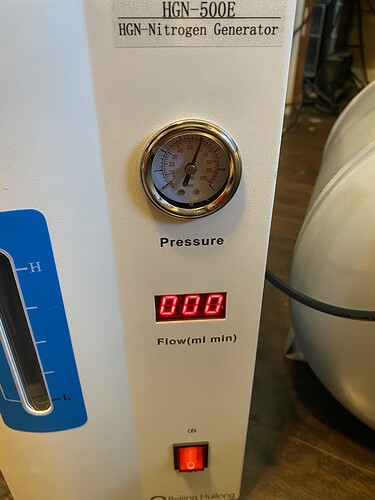

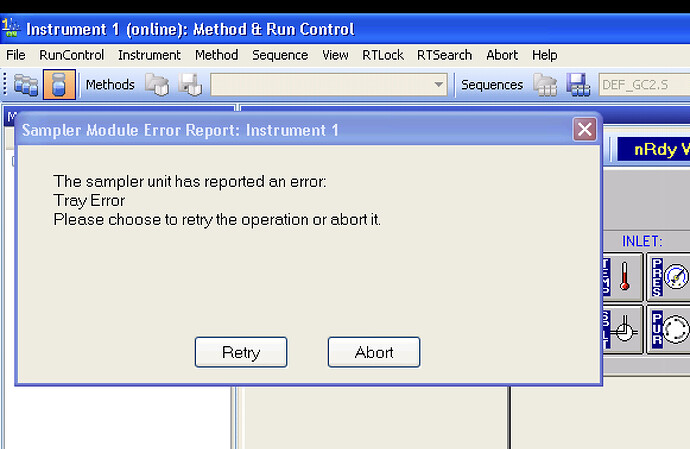

This appears to be an example of a “working condition” start up. After more than 10 minutes, though I did not time it unfortunately, the generator went from reading 0 psi and 080 on the display, to building up to 60 psi, display cycled up to around 400 something and began going down to eventually read 000

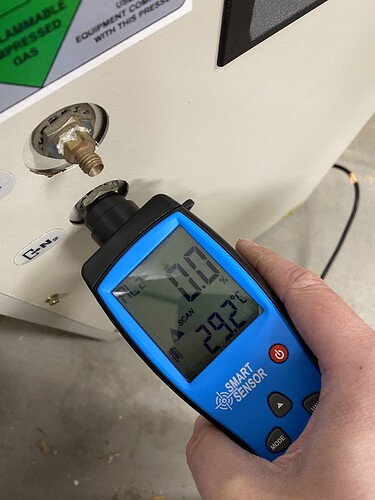

After opening the n2 outlet to exhaust the gas and allow flow from the generator, i tested with my o2 meter. I was able to get it below 1% o2 by holding the output line from the generator to the sensor of the meter. Unfortunately it’s too cumbersome at the moment to get a good picture.

Not entirely trusting the generators flow meter, i hooked up my new Agilent flow meter and to my surprise, a 20ml/min variance which I can attribute to sampling rates and level of accuracy of the sensors between the two devices. I’m reasonably confident.

Flow rate is looking good…

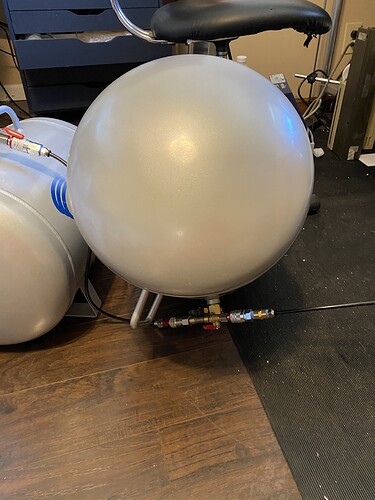

Not entirely trusting the high output of the generator just yet, i closed off the storage tank, allowed air to build (knowing there is going to be a mixture of oxygen in the tanks that need purging.

Waited a few minutes then released the built up air and tested it, as I expected the o2 meter shot down from 21% or so to about 17 before climbing a bit before eventually beginning to fall again. At this point I’m pretty satisfied the nitrogen generator is pumping out highly pure n2.

For some dumbass reason the steel air tank (originally got the aluminium, should have gotten 2 of those instead…) has no drain port; so, i have inverted it best I can to better allow oxygen to be purged next time, sparing as much n2 as possible.

Currently I am going to allow this to run. The rate is anywhere from 400-600ml/minute (having no fine controls just yet), the 20 gallons of air for the tanks to move from 0 to 15 psi should take about 2.5 hours by my math.

I will aim to, every 3 hours or so, put my o2 meter in a ziplock bag, and purge the output from each tank into the bag. Once the o2 meter beings to reliably indicate all likely o2 has been purged I will begin to fill up the tanks to their capacity (60 psi, apx 40 gallons n2 each, compressed) and should take something like 10 hours to do.

Next, I need to setup a pressure relief valve inline somewhere so that when the tanks reach 60psi of pressure, or probably less, it will begin discharging into a line which i will direct into my glove box.

I suspect I will need to get a series of heavy duty inline desiccators to further dry out the air prior to the zero air generator