Everything is mechanical except for the solenoid attached to the purge line (I believe as part of the split splitless injection).

Can you hear the solenoid open?

I haven’t tried to push flow through with the machine on yet, so no, I haven’t had an opportunity to test it. If one is bad, hopefully the other is functional.

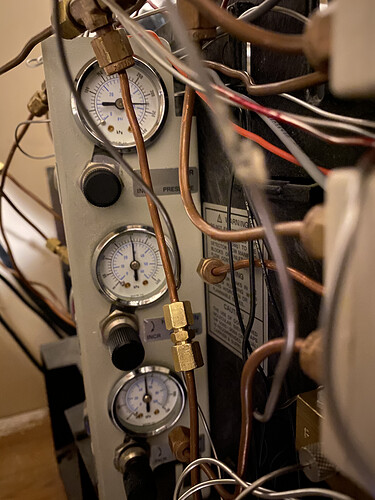

I think my next step is pulling the manifold out and chasing down any leaks under compressed nitrogen (Speaking of nitrogen…![]() ). If I can seal that all up, I’ll test that each valve is pushing out gas on the manifold. Perhaps test at the injector prior as well to verify flow. Not sure

). If I can seal that all up, I’ll test that each valve is pushing out gas on the manifold. Perhaps test at the injector prior as well to verify flow. Not sure

On the plus side, the air and hydrogen lines feed to the FID without issue, so I guess there’s that

I’d try turning it on. Won’t hurt anything and I bet you have a valve that’s closed. Just don’t let it heat up with air in the column.

I’ll give that a try. Right now the GC and I are not on speaking terms

I’m waiting on a pencil filter on mine that I’m hoping will solve my water issue. I’ve only baked out the trap for like 40 hours so far lol

How I feel about this entire project… ![]()

I’m excited to watch your progress, I think you’ll be beating me to that chromatogram ![]()

Yeah pretty much lol, hurry up and bake

And FYI, I already have a chromatogram it’s just horrible and has so much noise you can’t even see the injection lol. It’s still on for the first meaningful chromatogram

Well in that case…

Someone with better meme skills can throw out faces on there ![]()

Okay lets see:

- tore injector manifold out

- verified and placed gaskets in solenoids, gauges and fittings

- added retaining nut (whoops)

- tightened down the fit swaglok (single biggest difference in measuring flow

- hacked together 6 connectors, tied back into pressure gauges

- added back pressure gauge manifold

- realized hydrogen was my carrier gas, not nitrogen; replumb mass flow controller to hydrogen

- hooked up nitrogen line

- hooked up hydrogen generator

- tested connections for hydrogen leaks

- tighten, test, fix

- repeat the above an unnecessary number of additional times

- finally get all hydrogen leaks plugged (best as I can check so far).

- test flow setup with broken column, get it all working then do it again with rxi-35Sil MS

- setup injector and column flow for the following:

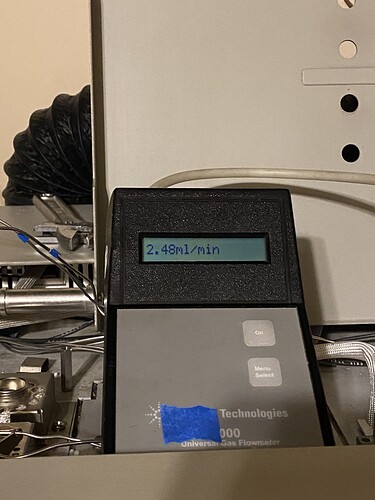

- 2.5ml/minute hydrogen at the column.

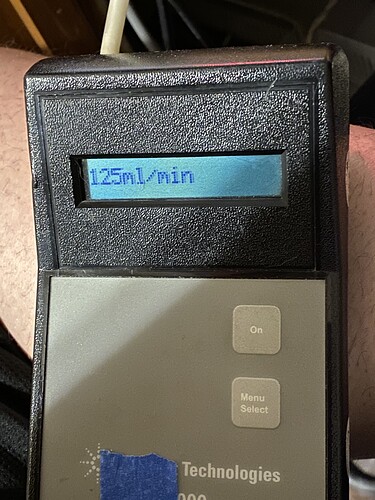

- 125ml/min at the split vent

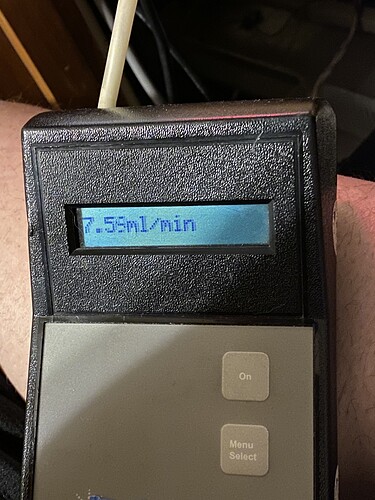

- 7-8ml/min at the purge vent

- setup FID flows as flows

- using a base of 2.5ml/min as the constant column flow

- adjust nitrogen to a total flow volume of 50ml/min (2.5ml hydrogen from column + 47.5ml nitrogen makeup gas)

- This requires setting a inset screw adjustment on the aux knob on the FID manifold.

- adjust hydrogen to a total flow volume of 90ml/min (40ml/min hydrogen)

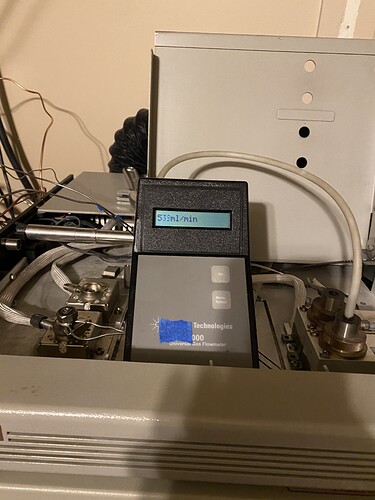

- adjust air to a total flow volume of 540ml/min (450ml/min air)

Actual values recorded as follows:

Hydrogen flow at the column

Flow at the split vent

Purge vent measurement

After adjusting aux (nitrogen) makeup gas at FID manifold

After adjusting hydrogen flow at FID manifold

After adjusting air flow at FID manifold (and fiddling with input pressures along the way)

Column head pressure at about 6 psi

- air at approximately 48 psi

- hydrogen at approximately 30 psi

- nitrogen at approximately 30 psi

Could it be? Could it actually be time!?

Hop into Chemstation, and… “GC not found” (i hate everything). After remembering, Windows, reboot and all is well.

Get the instrument online, program the method for the following:

- 220C starting temp, hold for .1 minute

- 35c increase per minute, until 330C

- hold at 330 for 0.9 minutes

After apparently breaking the first 1 ul syringe and trying a second run with 1ul acetone

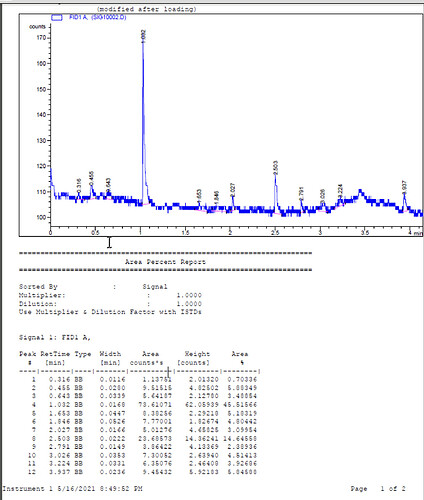

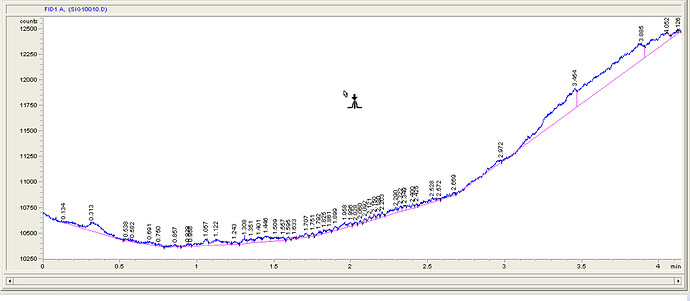

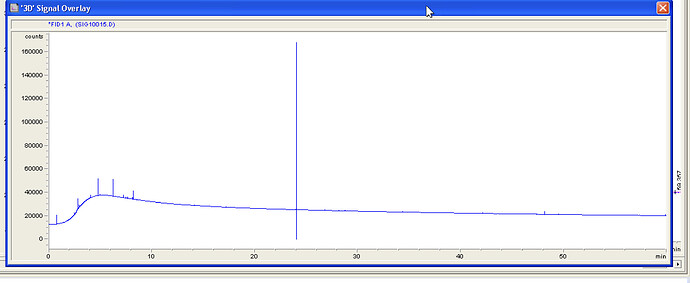

Indeed it is, after however many months, the GC puts out its first chromatograph (1ul injection of acetone). ![]()

Things to do next:

- Order a bunch of 1/8 copper tubing

- order a bunch of 1/8 OD 2 part ferrules

- with the above in hand, replumb everything

The chromatograph is super noisy, I’m left today wondering what the cause could be.

- The column I have is used, that could be part of it.

- I’m not exactly sure how clean the cut on the column end was (being relatively inexperienced at the procedure).

- my input air could be the cause (I think most likely)

- my nitrogen could be the cause (second most likely)

- my hydrogen could be the cause. (I think least likely)

My air and nitrogen are both sourced from my nitrogen generator. I do not know if the air that comes out would meet “zero air” standards. I have a zero air generator I will be putting in line to see how it may affect things.

If that doesn’t dramatically clean things up I will plumb inline a carbon block for filtration and a desiccator because, well I have them and why not.

I’m going to have to revisit the Agilent GC troubleshooting videos regarding noise. I believe the following may be next:

- replace inlet line and o-ring

- replace inlet septum

- probably re-cut the column ends (though maybe not unless the above doesn’t work)

I’m extremely pleased, I can see the starting line off in the distance

Welcome any advice on reducing the noise @SidViscous @Chaboes @bigbone @Cassin @kcalabs @Dr_Jebril (I know I’m forgetting a few…)

Might be time to bake the column at 350C for a couple hours?

I need to remember to vent the purge and split vent valves out somewhere (hydrogen gas)

Once all thats working manually, i think I’ll try and hook up the auto sampler. I noticed injecting the samples felt inconsistent to my hand, and one felt like it went deeper. I suspect long term if I can get it to work, the auto sampler will at least be consistent

Congratulations!! It does the thing!!!

Recommendation for noise is to first replace the inlet liner if it’s used and then follow resteks column conditioning instructions. In other words: “when I’m doubt, bake it out”. Also looks like you have a good amount of peak tailing so you may follow troubleshooting for that and see if it helps you with your baseline noise.

Well done sir.

For cutting column - it is seriously easy. This guide shows just how ease. Score and tap - anything more and you get jagged edges.

Can you “define” super noisy? Cause what I see in the one you posted doesn’t look that bad at all.

Your signal to noise ratio is pretty darn high from what I can see here.

I agree its probably something to do with your gas or maybe even your acetone. But it still looks mostly okay. You could probably update the integration method as well to control what is being seen. There’s at least 3 or 4 other peaks there that look like contaminates to me though.

So excited that you are getting chromatograms out!! <3

Not adequately! Mostly the up and down from the chromatogram suggests to me a not so stable baseline, but, I don’t know.

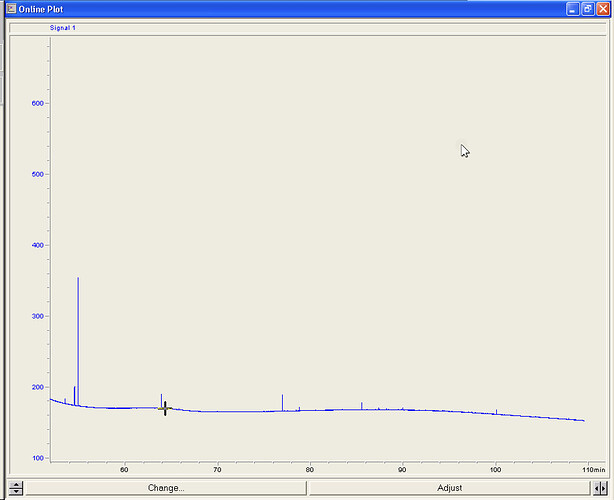

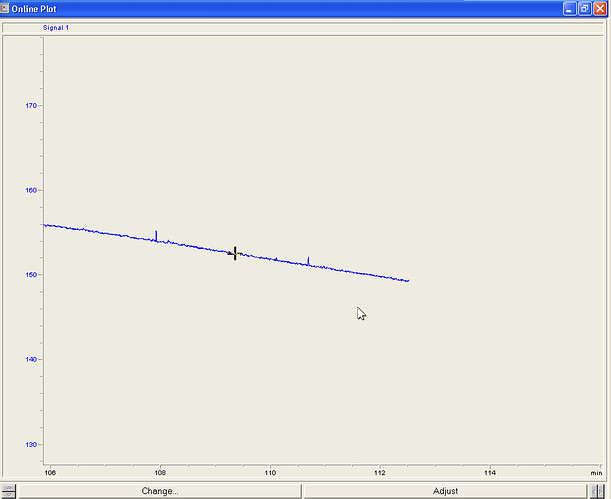

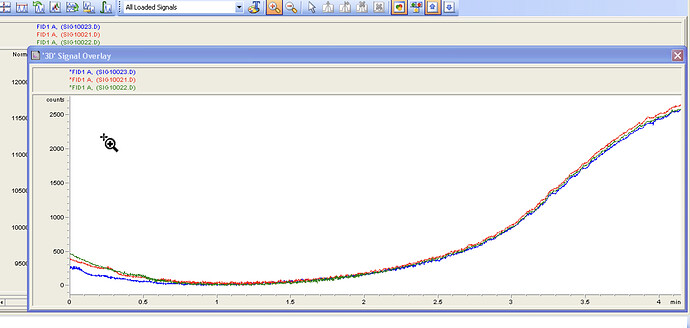

Doing a bake out now, you can probably see where I started the bake, and where I realized my nitrogen was off (whoops)

Already seems like we can see the noise going down?

I guess we’ll wait and see to find out where the baseline settles at.

So far, no changes to gas, column, inlet liner or septum

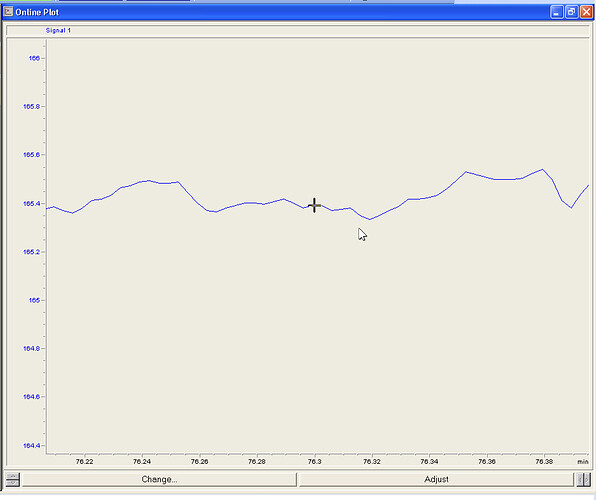

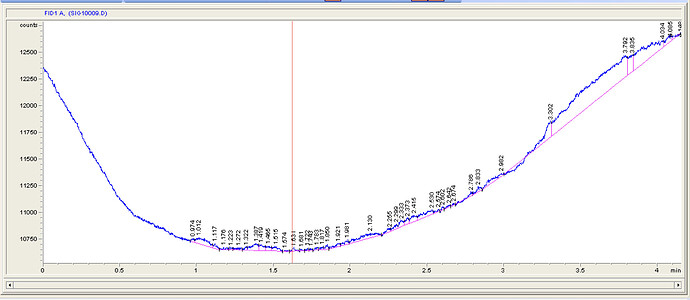

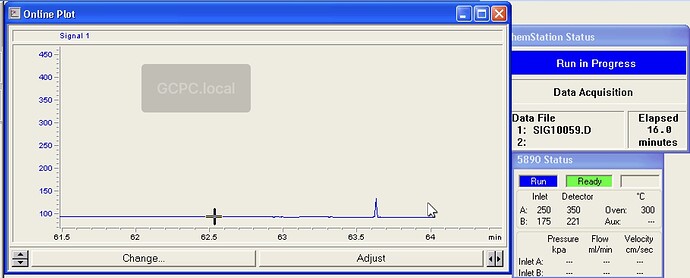

Replaced the liner, o-ring and septum at the inlet. Discovered I did not have the detector temperature set at all. I have no idea how that affects things.

Two blank runs before, will post the ones after the above changes

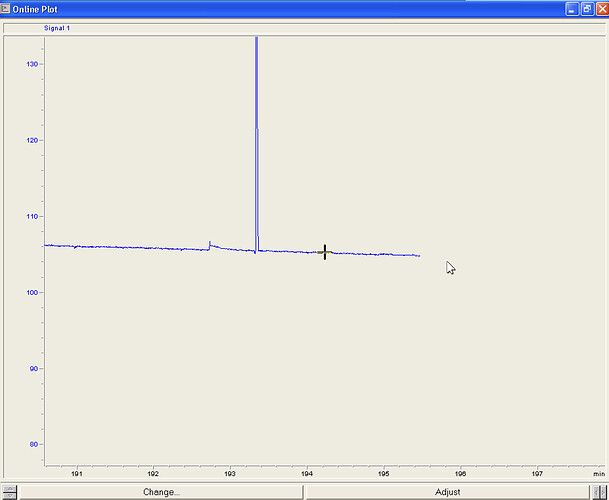

After:

I’d say that looks pretty clean? @Cassin @Chaboes thoughts?

I’m unclear why the baseline increases towards the end, is that expected? Seems like it may be related to temperature

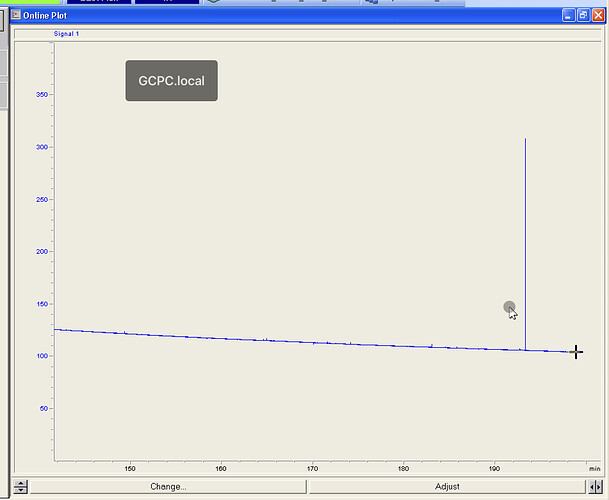

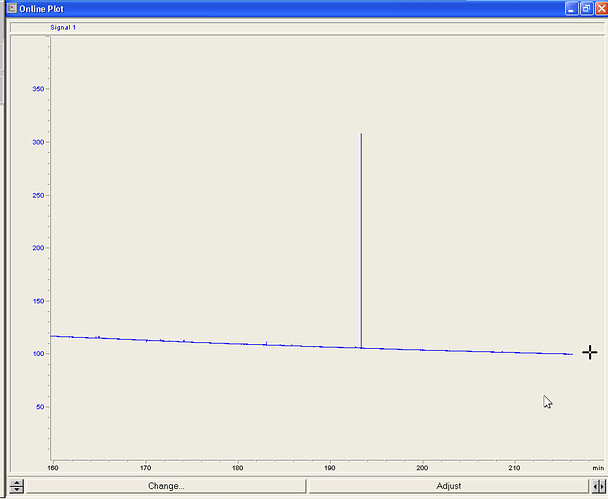

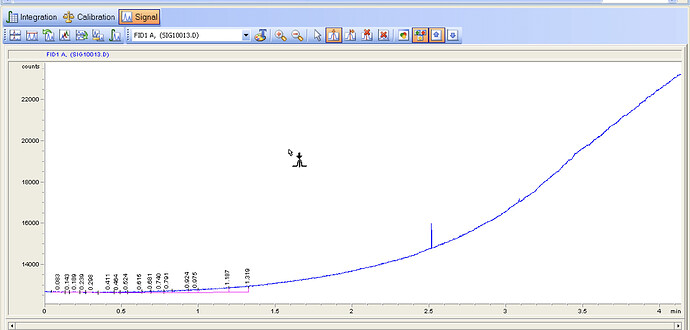

Ran a basic method, 350C oven for 60 minutes, 350C at the detector. No injections

Letting things settle, run 3 runs back to back to see how they compare

Rising baseline towards the end of the run is normal just ensure it is not interfering with any peaks of interest.

The baseline definitely looks cleaner, I think maybe there still a little tweaking to do.

EDIT: Just realizing your Y axis is in counts (mV) not pA which I am used to, so that certainly makes the baseline look better. 1pA = (approx) 2048mV (counts)

If you are running an autoinjector I would do some solvent injections, I would like to see how those turn out.

If manually injecting, butane from a lighter taken up into your syringe and injected will work well.

I think oxygen may have gotten in the column. I did a septum change with the oven still on (whoops) and haven’t gotten any peaks since ![]()

I mean certainty not ideal, but I would not expect such drastic results. Was carrier gas still being fed into the inlet during the septum change? Is your carrier gas flow still able to be found at the detector?

Carrier flowing yes, no makeup gas on the column on my machine though. I cant think of why none of my injections show any peaks now; no solvent or otherwise?

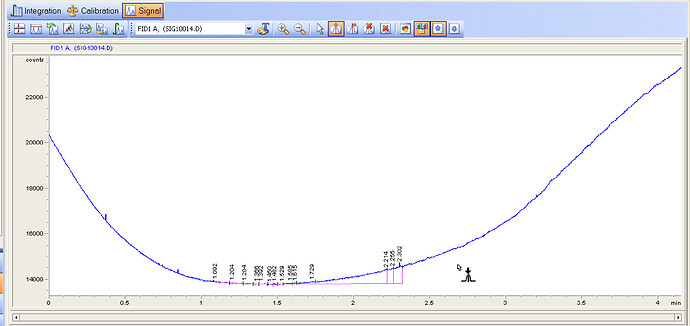

For grins and giggles I just put this guy in. I know its excessive but its the only other column I don’t mind getting wrecked [if it happens and isn’t already]. Currently pushing gas through it before getting up to temp. Not sure how to exactly modify the method, maybe slow the ramp on temp by 1/4 to account of that extra length?

Doing the bake out on this column, am I wrong in thinking this looks particularly clean/sharp? @bigbone @Chaboes @Cassin

When did this start?