Yesterday after doing a few injections, particularly noticed it after doing a septum change, which was done with everything hot ![]()

Any chance your FID flame went out?

Yes, its possible and I might not have been aware.

I was looking at the signal numbers coming out, which were consistent with the baseline. It seemed to me to be functioning as I have observed.

However my experience here counts for very little so absolutely I could see that happening and not being aware of it

Hey man, if you changed the septa while everything was hot there’s a good chance air got into your column at an elevated temperature. Not good!

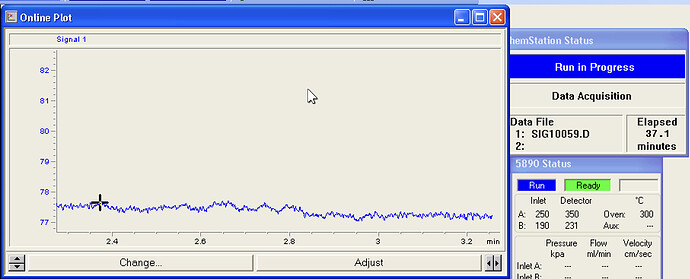

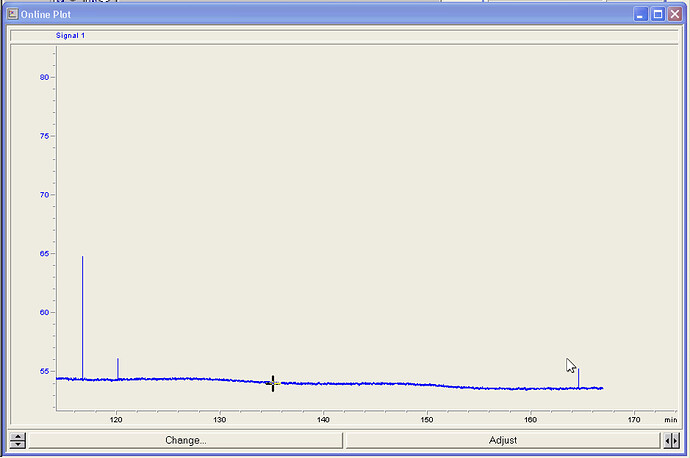

Would anyone have an example of a stable baseline signal from your FID? Wondering what it should look like, in contrast to this:

Detector temp - I always set this at the upper limit of the stuff I’m looking for. I’ve had some people tell me that if your detector temp is too low that you’ll get gunking up of stuff at the end of your ramp. You are not ramping right now - so you shouldn’t see a bit difference at all until you actually start trying to use your column to get separation - as those compounds as they come out will behave differently at temperatures.

Most established methods will tell you the ramp, starting temp, ending temp, and detector temperature - so you won’t have to guess at this that much. And you can always tweak it to work for you (and then validate that it performs the same over and over).

I think your baseline is looking good. I’m more concerned with it looking the same each time and how it looks as “noise” compared to the samples you want to run. Too noisy and it will be super hard to get nice limit of quantification…and maybe even limits of detection.

Here is Agilent’s guide on fixing baseline issues - I think you are doing just fine with this already. Adding in a ramp will let you know if you are just seeing degradation because of heating at the same amount the whole time or if you have other issues in play.

In general - your machine is performing the same each time - as long as it performs consistently and isn’t too noisy - you can integrate appropriately using it. Repeatability is the first step and it looks like you have it. ![]()

All things can be baked out. ![]() You can also always just push your carrier gas through it for a bit to remove any weird stuff.

You can also always just push your carrier gas through it for a bit to remove any weird stuff.

I’ve done some really TERRIBLE stuff to columns… and I’ve never had one just stop working completely. Check your connections and pressure. If you have pressures everywhere…disconnect the detector end and put the dang thing in a beaker of water and see if there are bubbles… Then recut the end and reconnect.

If you don’t see bubbles - then you may be out of your carrier gas… or it could be clogged, at the injection port. This is super easy to do - clogging things on the front end. Its why people do a lot of filtering before sample injection, etc. You can cut like 2 cm off the end of the front and put it back again. But only if you don’t see bubbles. If you see bubbles its flowing - its just not making it to the detector.

Figured I’d point you to some good articles on this stuff.

For baseline - Restek has a solid article that talks about the ramp its impact and what “column conditioning” does to make things run nicer. ![]() This also discusses things like… what to expect from different kinds of columns, methods you can use, and thoughts on how to fix things. You issue is not unique and that baseline will get better with a ramp and some more conditioning time on the column. How old are these things? You’re talking about being okay with destroying them so I assume they are not brand new.

This also discusses things like… what to expect from different kinds of columns, methods you can use, and thoughts on how to fix things. You issue is not unique and that baseline will get better with a ramp and some more conditioning time on the column. How old are these things? You’re talking about being okay with destroying them so I assume they are not brand new.

Here is an article from Sigma Aldrich on tips and tricks for doing this. You’ll notice that the baseline they are saying is “good” has much more noise than yours. ![]() This looks great - and I wouldn’t worry about that so much. Now move on to other things like consistency and getting solid peak retention time and uniform peak shape across multiple injections. Also - please note this article from Sigma is all about getting you to buy their reagents and stuff - super helpful, but don’t feel like you need to have the most expensive everything… unless your method says you have to do so and your looking for really low LOQ and LOD values.

This looks great - and I wouldn’t worry about that so much. Now move on to other things like consistency and getting solid peak retention time and uniform peak shape across multiple injections. Also - please note this article from Sigma is all about getting you to buy their reagents and stuff - super helpful, but don’t feel like you need to have the most expensive everything… unless your method says you have to do so and your looking for really low LOQ and LOD values.

Thats some really great info @Cassian, thank you for sharing!

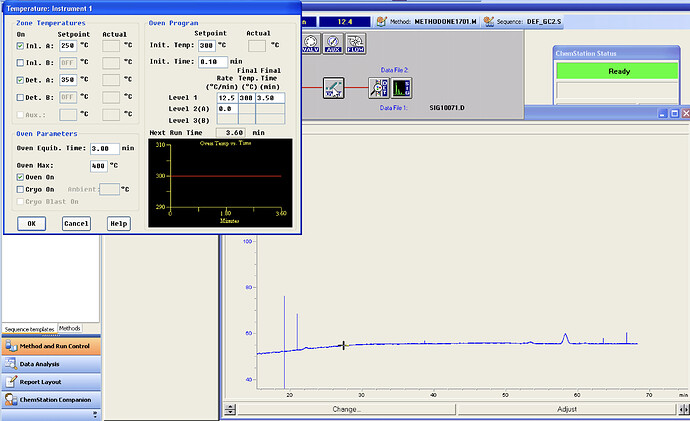

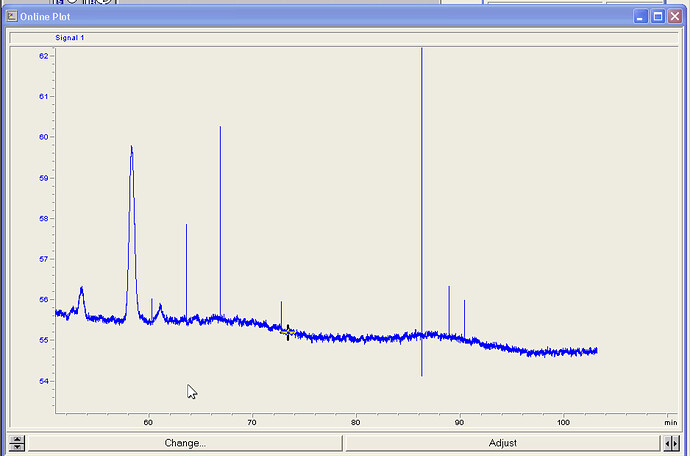

I finished the bake with the baseline settling a little low signal wise but otherwise looks the same. I do notice i get strange peaks as the oven cools so I think a ramp conditioning may be next.

I don’t have a method for this column, for grins and giggles i’m going to run a blank run 3 times using the existing settings, temp from 190 to 300, 12.5C/min, and see how it looks and decide what next to do.

All these columns are second hand, their condition unknown really. If the 35sil can be saved that’d be great - though I have a replacement on the way just in case. Figured better to learn on a $100 second hand column than the $400 production one ![]()

I had wondered if the installation of the column could be an issue. When i took it out, i remembered to check the fittings and sure enough a few had loosened. This could be part of my problem as well.

Some experimenting surely to come. Although getting some standards is proving an annoyance ![]()

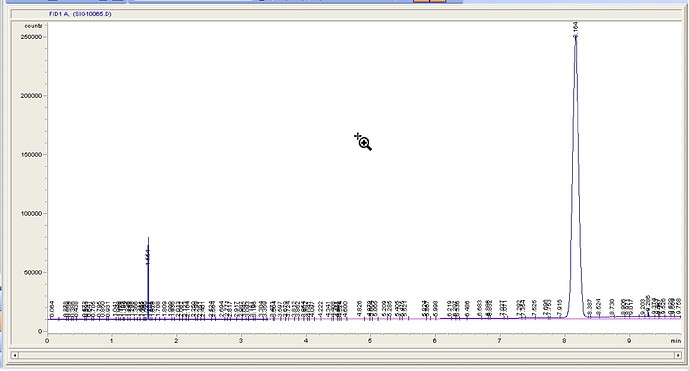

Running some simple samples now. Acetone elute at over 8 minutes on this column (i have no idea what that front peak is)

Second injection, this time with acetone and CBD. Unfortunately the CBD eluted after the window. I set the method oven final temp hold time to 5 minutes and doing another run now. See what happens

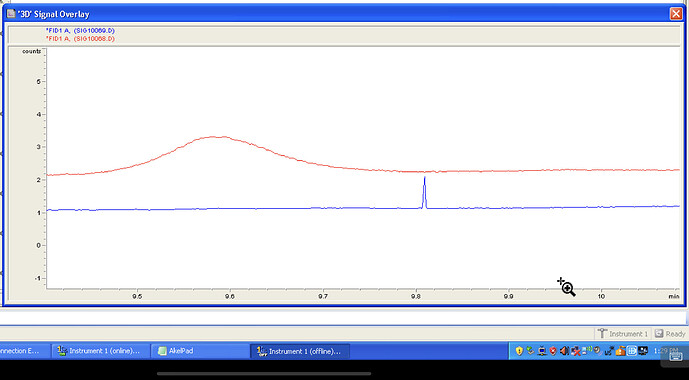

This was from the same, “1ul” injection (from a 5ul syringe). Clearly a bit of variance. Bigger peak is from second injection

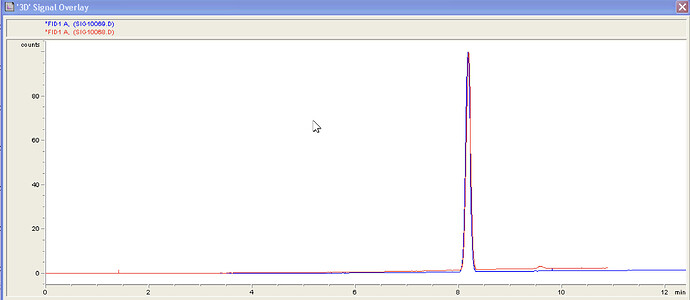

Running the sample with CBD again, looking better:

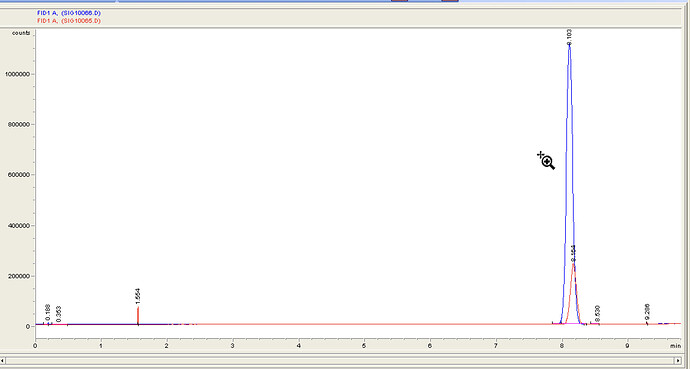

It looks like two compounds eluted after the run, so I’ve decided to add an additional 90 seconds to the oven time (3.5 minutes now) to see if I can’t capture them

Literally me watching and waiting for peaks to elute after 8 minutes

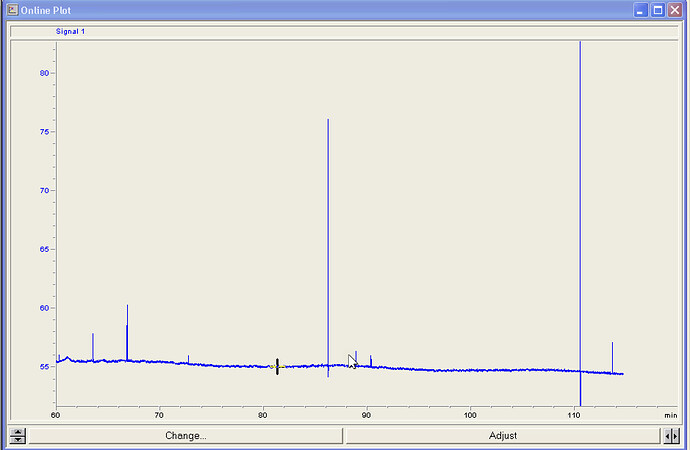

Second run, same solution. Not sure what to make of it yet

Acetone peaks are spot on

Very well done! That instrument has been brought back to life (albeit kicking and screaming it seems)

I’ve never seen a solvent peak that far into a run lol, what is the inlet temperature and final hold temperature?

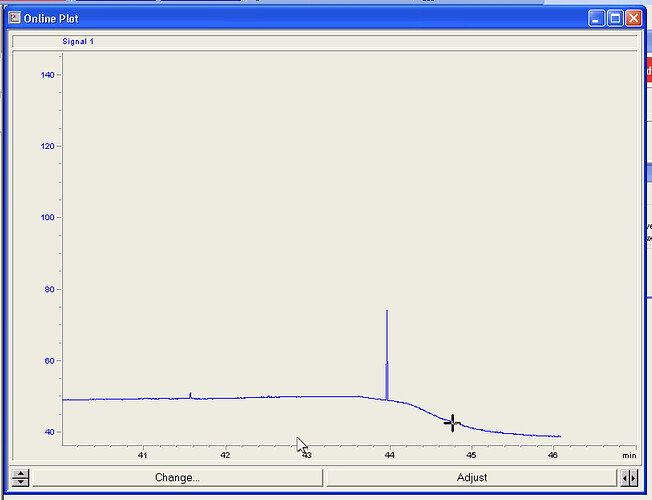

I can only imagine its because the column is 60m long? My method runtime right now is very much not adequate… lol I’m sure you can see why:

(I set the oven temp to 300 so it can idle there and see what happens, otherwise it was 190c)

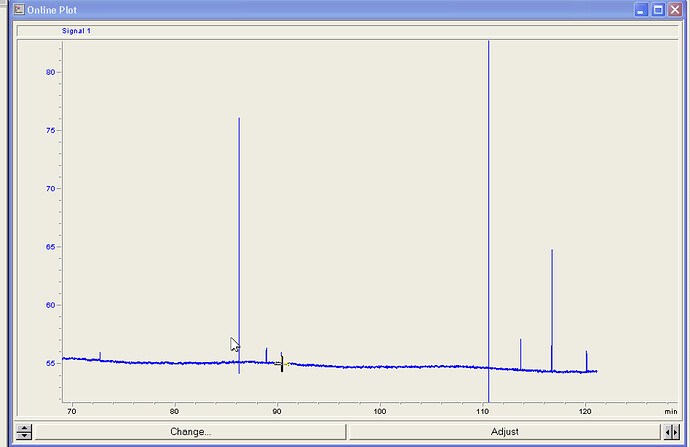

Still getting stuff 40 minutes later

Still stuff coming out. I should mention this run was using a sample from d8 crude

Separation on this thing must be kind of insane?

I would go a little higher with the final oven temp, helps get rid of some pesky stuff (~320-330c). This may help with residuals.

I would ramp from 180-190 to final at 5-10C per min with a longer final hold, I doubt 10min is enough for that length of column especially depending on other factors like column flow/pressure.

Those hits that have no area under them can be related to gas contamination or even dust in the air, it could be carryover but usually if it took that long to get to the detector then it will be a broader peak.

Only reason I didn’t was because the column mentioned 300C as the high point; think it should be fine regardless?

10 minutes definitely isn’t long enough, glad I let it run. Are the small, sharp peaks noise or of interests?

Usually, they wont integrate so it likely wont be a problem, even our GC that is in standby 24/7 has one of those every once in a while. If you keep getting them often after the system has been up for a while (48-72hours) I would have more concern but with that old of a system getting started I’m not surprised.

If that is the max temp for your column I would not exceed it.

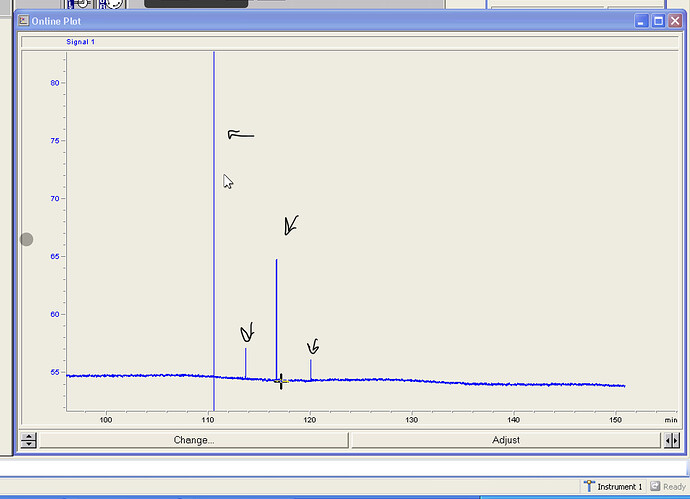

Do you mind pointing these out on one of the images? I’m a little unclear as to what we’re referring to as hits without area under them. I have my air line directly supplied to my nitrogen/air generator with you a tank in the way. I’m wondering if the compressor kicking on/off in the generator could be having an impact

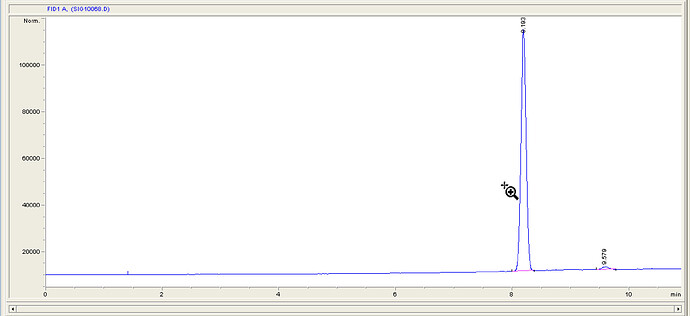

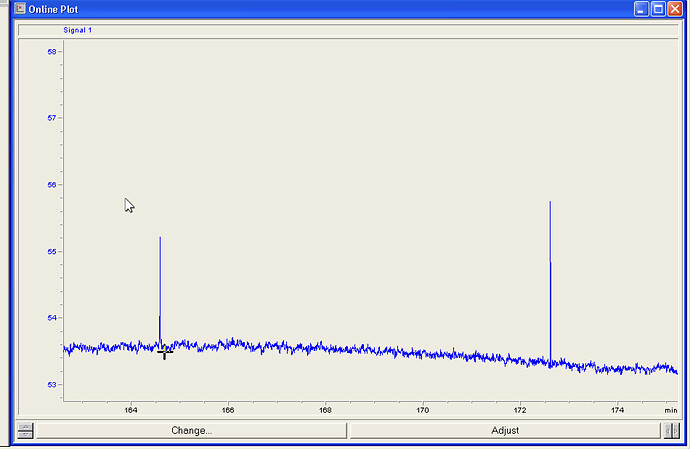

To be more clear, are these noise or of interest? I ask because they come out very sharp, rather than wider as the acetone (and I’m guessing heptane) peak at the beginning

I ask because, I would expect this to be d8, d10, d9, CBN? And I don’t know if this should be considered an artifact based on the peak width, or not

I also ask because at the moment I’m kind of letting it run to see when i get a clean consistent baseline and I’m getting what I would be inclined to think is response to compound

If you zoom into the peaks can you see a gaussian peak shape?

Otherwise:

I would think so but I defer to your experience:

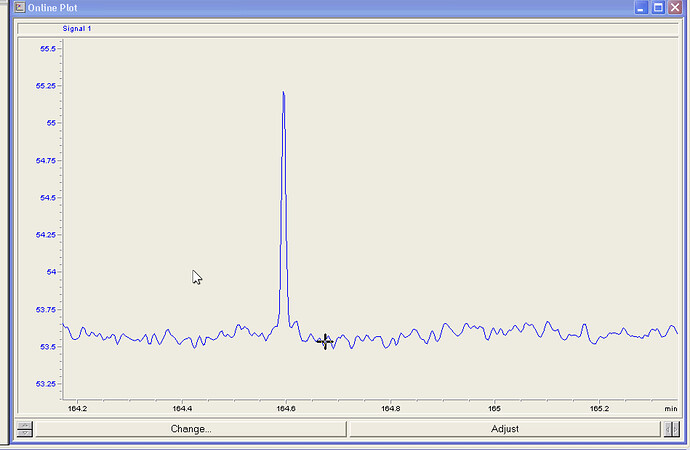

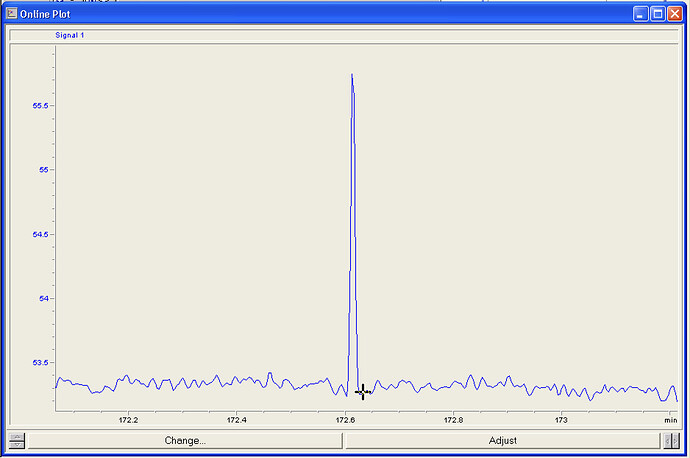

Zoomed in, then each peak

Definitely could be baseline spikes, though that would be somewhat troubling i suppose as this sample sample produced a few good peaks yesterday on the other column

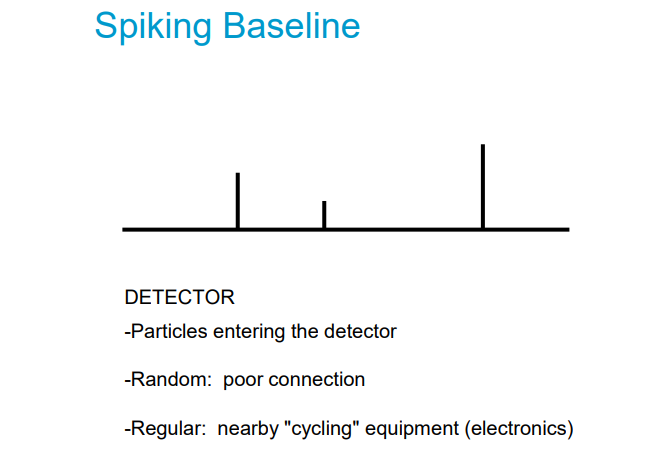

If your minimum peak width built into Chemstation is not picking it up as a peak because it is too narrow I would bet it is just a spiking baseline.

You may be putting the horse in front of the cart here…I know you are anxious to run samples but the issue is if you do not know a retention time you will be flying blind. You can start working out a baseline and repeatability for your system with things like caffeine but real world samples are going to be meaningless without RT. If we knew d8 came off this column at 172.6 min you would not have to worry whether it was baseline spiking or missed analytes.

Even if you have isolate or distillate that is going to be a better use of your time as compared to a crude product.

I agree, largely these runs are for experience and practice rather than practicality (figuring my 35sil was dead). I intend to replace the 35sil column and re run the conditioning and see if maybe it was related to fittings. I think I also did not have the column going into the detector long enough initially.

We’ll see, this column is fun, but the 5 minute runtime is probably better to learn off of

The system overall seems to be operating well though. Excited to see what you will do.

Also this is a helpful pdf to keep in your back pocket.