P.C. FLW710 Propane or butane/propane mix is fine. Haskel is not versed in the 710 industry, Just need to make sure we have the right elastomers and we do change outs a ll the time. . I have them on the shelf and best pricing too ! The 59025 (series) or EXT420 (parallel) (can be set up as dual stage Parallel/series action to really drawdown) are under $3k patrick.comfort@flw.com 714.622.2000

Call me if you guys have any questions! I do sizing and engineering on these all day long! Patrick 714.622.2000

4:1 ratio + drive air. Not liquid capable gas transfer. The 59025 refrigerant model can handle gas and liquid to ATM-1250 psi

Blackmer sliding vane pumps

Sounds like butane membrane system is not too far off

I’ll have my hydro carbon membranes next week, then the fun begins

Hmmm… ![]()

do you happen to have a source you can point me at for that?

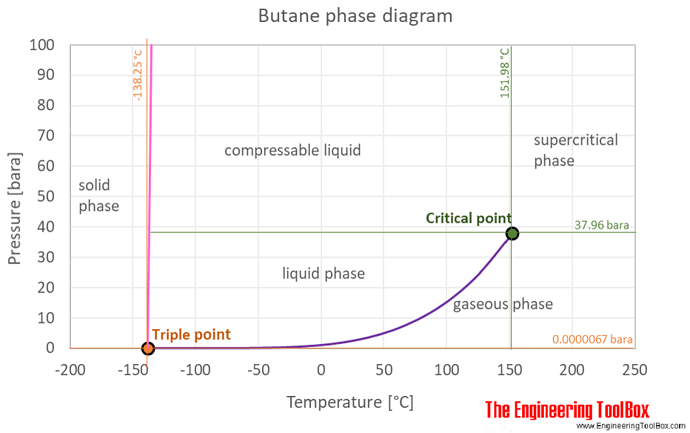

Can you explain how to achieve gas phase butane at 86bar?!?

The label clearly states I can run the INPUT side at 1250 PSI. Even at half that pressure it seems impossible to obtain gas phase…

I’m assuming you see my dilemma?

I think he might be saying that Haskel doesn’t want that pump run like that

I though the Hydra-Cell’s would work with butane for membranes?

which was why I went to Haskel rather than you lot first ![]()

if they didn’t want me using it that way, why write numbers on the label that can be interpreted no other way?

You’ve apparently not bought enough used cars my good friend, it’s always in the fine print. It’s the technical superposition theory: you may only reach the limits of each of the desirable technical specifications individually, never at the same time lol. To be fair, the pump can definitely do it, they just don’t want to warrantee the parts. Not that Haskel really does that anyways

And why can’t we use a liquid transfer pump like we use for hexane and heptane. N butane doesn’t exceed 50 psi in normal circumstances and definitely shouldn’t exceed 100 psi

Are you saying you still in a liquid phase by the time your hitting the EXT? What is temp your going into the pump?

It needs to be at vapor by the time it hits the pump. We see a lack of gas volume being generated in a lot of cases which slows down recovery… Especially the guys that are trying to overcome backpressure in the recovery side as the butane needs to be cold and going to liquid before it hits the tank (and after the recovery pump and it will “wick” drawing the gas thermally which really helps when you get down to the end of the run and pulling vacuum. Correctly sized coils and a good chiller ( or a good dry ice setup ) will get any back pressure issues under control.

No. I’m saying that I’d like to use the pump for liquid.

It is rated for 1250psi butane. At 600psi it is impossible for the butane to NOT (thanks @SidViscous) be liquid. (See phase diagram above).

ipso facto the pump must work with liquid (unless the numbers on the label are complete horse shit).

I’d like to understand why that might not be true. You certainly don’t seem to buy the logic…

As @Apothecary36 notes, I won’t be much above 50PSI (which will still mean liquid!! )

Looking to circulate over opaline silica as I have in the past. Hoping to use the tools I have, because they look to be rated for the task.

You can. The debeem boxers work great. The stainless ones inspire more confidence imo

I’ve got one…but I’ve also got six ext420’s

Just call me recyclopath…

I think you meant to say impossible to not be liquid.

The pump will pump liquid. If the discharge pressure gets too high, it will stall. As long as it doesn’t try to pump supercritical or solid you’re pretty much good

Jesus lol

Yep I did. And I’m gonna go change it.

Really shouldn’t get on here until I’ve actually gotten my coffee in me.

I’m also just gonna have to see for myself how this works. Although I’ll probably try poking at Haskel again just for completeness.

Thanks for the fact checking and reassurance

re confirming the ext420 will pump liquid.

plumb the bypass discharges appropriately.

they WILL leak at dry ice liquid temperature.

just remember that your downstream fittings, gauges and vessels need to be rated for HIGH pressure as these pumps are unforgiving.