I guess its a shade cheaper from new surplus, but if the M03 or D04 are better suited I will opt for them!

Do you use acetone for recovery slurries?

D04 , as it rated at 2500 psi, is what i would choose.

Surely the higher pressure would be an advantage ?

There are other pressure limiting factors such as the membrane and housing rating. The Evoniks are rated to 60bar/870psi. The inopor ceramic is a much lower max at 15bar/217psi

Also in my mind, keeping the operating pressures as low as reasonable should be a goal as well.

Ah , i didnt explain my self properly, If you use the D04, you can use it at less than half power. So i was thinking it will last alot longer as its less stress on the pump.

I actually meant to say d03 this whole time. D04 is overkill.

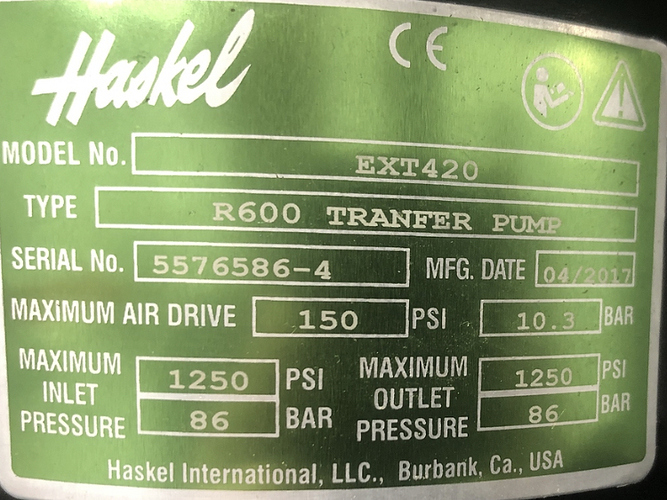

If I can feed this 1250 psi butane (r600), then logic says it must be liquid capable no?

Seems like propane would also be ok.

Am I missing something?

Haskel claimed they’ed call me back. The lied.

Yep! No problem with liquid at all, they’re originally refrigerant recovery pumps and they just stall if there’s an issue (no risk of damage to the pump either)

Edit: I see Haskel’s spelling abilities are about as good as their expedited replacement part capabilities. “Tranfer”

Tranfer pump work real good

Tranfer pump wook real good

Funny story, I handed Zubrick out as required reading in our lab and it got creatively relabeled as “how to extract weed reel reel good”

Almost identical to the high pressure feed pump I use for liquids I believe.

they leak with dry iced liquid butane.

just pipe up your blow off ports to a collection vessel.

But they’ll work ok on the warm side?

The serial # is EXT420…apropos I’d say

yep.

that’s the model number.

I blame @Graywolf and the other SkunkyPharmers for their work with Haskel for that…but it may not have been their fault.

4:1 compression

20 cu in displacement

ext420

well shit!

so the Haskel engineers put some thought into their tranfer pump

is that in single or dual stage mode?

I’ve got both setups, and recall @Graywolf discussing the plumbing he used to switch between the two.

I’m guessing single stage makes more sense for moving liquid butane unless I’m trying to squirt it through membranes (which is not on this weeks list of things to get done, but is intriguing)?

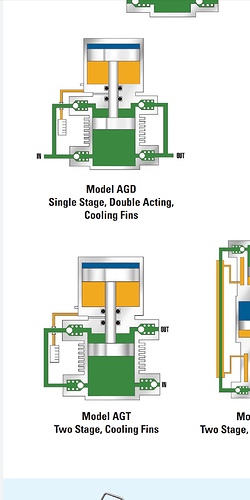

Here is a picture from the catalog that explains it pretty well

The AGD moves fluid to process on both the up and down stroke. The AGT allows higher ultimate pressure because the process pressure assists the drive pressure to compress the gas. Honestly, both of them pump a wicked lot of straight liquid. If you exceed their rating, it just causes the piston to stall and nothing to move (hence being safe for pumping liquids assuming you set your drive pressure in accordance with your relief device).