No those are solvent tanks.

My friend was specifically asking about this one, for bubble.

He doesn’t want to do BHO, I like to smoke bubble and rosin but not make it

And he wants to do hand washing

@raghanded posted something similar a few months ago and I still think that would be my “perfect” hand wash vessel down to the size and shape exactly. So perfect I still daydream what I’d do to it if I had that, a plasma cutter, a welder and a few other parts along with it. I have a very detailed idea of what I think would work perfectly in that scenario

The solvent tank, or the one I posted yesterday I think?

He wants to do it all by hand, I thought that was a decent shape and size but told him I’d check, and I thought it was jacketed but it’s not

I mean jacketing only matters a lot if the room is super hot, if he has a refrigerated room then it’s not needed horribly. It helps don’t get me wrong but if you use a lot of ice like I do it’s not really that bad if you make sure the water is down to temp first.

I showed him about a cool bot that we have at the bho spot and he’s already started insulating the room! But it gets a zillion degrees in the summer (norcal).

Thanks you!

No worries bro, good luck!!

As an aside, I can’t fucking remember but can people use an air lift, like for making compost tea, instead of a paddle etc… I forgot so much since my stroke (and remembered so fucking much too) but I could swear someone was using the agitation from that to make bubble, but don’t remember who it was or if it was just someone showing me their compost tea brewer

I use to use a conical fermentor with an air line for agitation then drained through staged bags. Worked really good, especially 12+ yrs ago

How do you get around the heat of the air compressor?

We used to use co2 like that in a conical fermenter. Helped with the heat but would clog with dry ice from time to time

I’m sure nitrogen would be a good alternative

Totally agree, this was 5+ years ago

A paid runner who bought ice all day. It was pretty big so 1-2 runs and swap

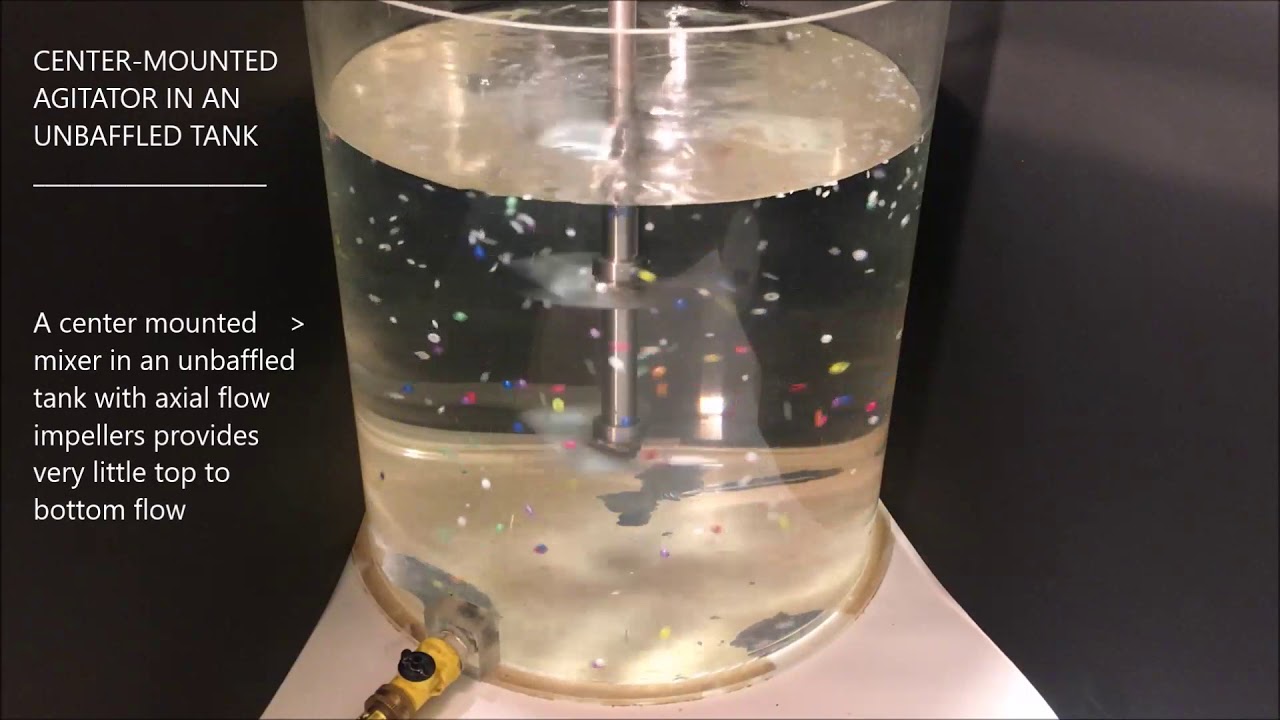

Hey guys, check out this video on YouTube about agitators used in solventless machines, some of which are described in this thread.

Take the video for what it is, as it is not a scientific study. It is a simplistic explanation of the importance of agitator and vessel design and how different designs affect fluid dynamics. I welcome you all to replicate and validate our claims. My goal here is at least to entertain and hopefully teach.

My opinion is that our machine, hands down, is the best machine on the planet. We took the time to design a fantastic system and are not scared to make those claims here. As I have learned, some people here are brutal and have way too much time on their hands. ![]() but I got a bag of popcorn, beer, and cigars.

but I got a bag of popcorn, beer, and cigars.

Yes, our machine is not cheap and it is not for everyone. Enjoy the video!

Nice video. Have you considered funding a study? It wouldn’t cost a ton for a University study using three-dimensional computational fluid dynamics (CDF) models and subsequent validation. There are programs available where the Uni may pay half the cost. You already have the 3-D printed vaned disk turbine impellers (Osprey and Mesclatore) and the higher shear radial flat blade paddle impellers.

Here’s a good article in Processing Magazine:

How computational fluid dynamics is applied to mixer design

Have you considered adding using dual-impellers, for example, a radial flat plant paddle impeller near the surface for greater interface agitation, offsetting your impeller, or baffles to your square tank? A CDF analysis of baffles on square and round agitation tanks would be interesting.

Radial flow with baffles in a round vessel using a flat blade paddle impeller:

Dual-hydrofoil impellers: High efficiency impellers designed to maximize fluid flow and minimize shear rate:

I’m considering your Magna Agitatore. But first, I’d like to see a video of it in use. I’m sure many other people would as well!

Specifically the efficacy of the deck sieves with different screen sizes and harvesting the trichomes from the collection screens socks.

We will be doing demos all summer. Hopefully, we get invited to some of the more reputable or recognizable brands so stay tuned. If anyone works for or consults/has contacts with a big name please reach out.

The sieve system will be featured this summer and hopefully, the demos convince the industry of its application. I feel strongly about sieves and I implore companies to stop reinventing the wheel. Buy a sieve from us or the dozens of fantastic US manufacturers that know what they are doing!

Yeah that’s about the coolest thing I’ve seen in awhile, seems like a great way to increase throughput

If I can talk to someone who has used it or see a video of it in use I’m buying it. @SamboCreeck.com are any units in the wild? What has been the feed back been so far? And is that your first iteration (I don’t like being an alpha tester, lol)?

Great post! So yes we did lots of CFD. Everything you see in the videos we learned from CFD or DEM simulations. We don’t post that work because it costs an arm and a leg if you have to rely on an expert to help you. Publishing that information gives competitors education and is something they need to invest in if they want to get into the game. No sense in making their life easy.

We did reach out to several universities. For the electrostatic separator we are developing, we reached out to a university and yes they would help but it would de 18-24 months before any research would be published. It has to do with their semester scheduling and PHD candidates etc… For us, the cost savings do not merit the long time frame. What we do instead is hire a teacher and some PHD students and have them liaison with my team in Italy. They explain the theory and engineering drafts and propose solutions. Those get prototyped and tested until something final pops up.

With the Mesclatore we worked out a round tank cause it’s cheaper to make and we already make several hundred a month. DEM suggested it would be great but it proved challenging. This is why you not only make models to verify CFD but also prototype to validate.

There are 3 long and boring YouTube videos that cover the design process in depth including some of the roadblocks we hit. We did try baffles, dual impellers, and so much more on our round tank. We already know the answer to all those questions. At some point, we will publish the findings but in the meantime, others should give it a go.

For now, my goal is to educate why our system is different and leave it to the user to decide whether it’s for them or not.

We did R&D and developed an SOP with Vibrowest and Justin at Green Mountian. We filmed a video with his system a few months ago. It gives you a basic idea of how it works.

Justin had it nailed down. We just went back and forth with Vibrowest on how to make it better and improve the workflow which he already did well.

Justin has a basic sieve with a vibrator on it. Hash piles on the side opposite to the motor. Even 2 motor designs aren’t that effective. A rotary vibrating screen that circulates is the most efficient way to do it. You are limited by the diameter of the sieve, and how many decks you can stack. But with the right SOP the workflow is as efficient as possible.

There is no beta testing really. These systems have been around longer that we have. The SOP was more important than the machine. We will be testing a US made sieve this summer, exact copy of the Vibrowest, simply because logistics are so crazy. You will see the whole system in action this summer and in person at MJBIZCON Booth 9031.