Just realized I am ignoring my garden, which is the 3 pounds I am looking to process when harvested/dried/cured. Gonna go feed them.

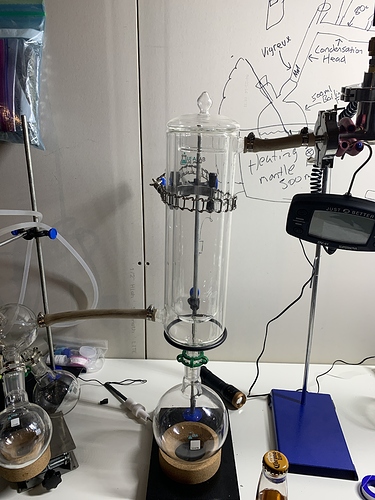

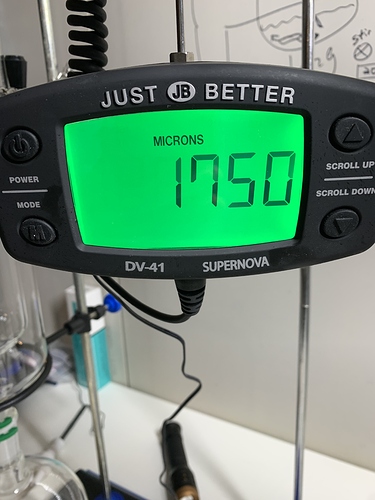

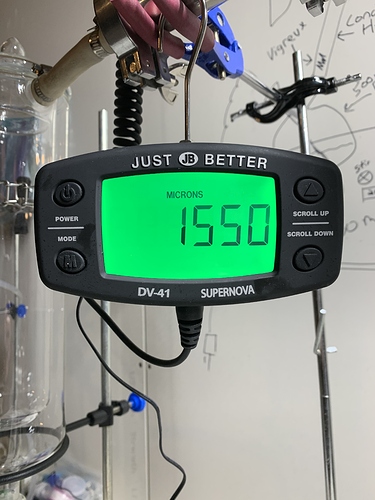

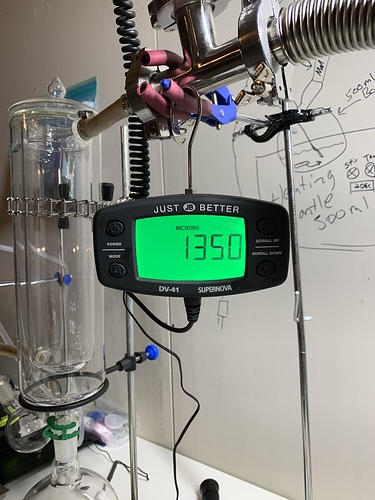

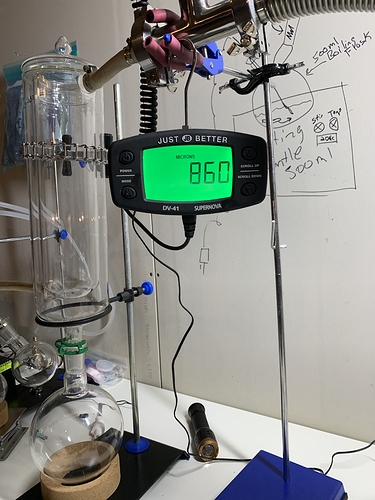

I left the still with this reading on the vacuum gauge. All joints greased. More fooling around tommorrow!

Looking good only thing I wan t you to check is if you have enough hose between cow and coldtrap

When the cow get s turned without the hose pulling her back

![]()

@Roguelab you are correct, when I turn the cow, it messes with the cold trap. I’m guessing that’ll cause trouble. I’ll make it a bit longer.

how far does the pump pull down without the rest of the gear attached (blank off value)?

Try vacoil.com. Its what i use and have noticed better vacuum and its cheaper than most at 150 for 5 gallons

It goes down to 30 micron if I connect the gauge to the vacuum block off valve. The lowest I was able to get it was 130 micron with the stoppers in, no thermometer adapters.

Have you tried plying it with warm ethanol?

If you watch your gauge you can tell which joint is leaking by judicious application from a spray bottle…

Note: Helium is cheap, and much safer. Spraying solvent around at 20C above its flash point is not to be taken lightly…or was that not to be lit?

![]()

I can’t remember…

Party city or wallyworld stock helium tanks.

30.00 or so. Should last nearly a lifetime of chasing spd leaks.

And maybe 3 weeks if you wanna talk like a chipmunk.

Its kinda a waste tho. Easier to spin joints while you watch your vac gauge

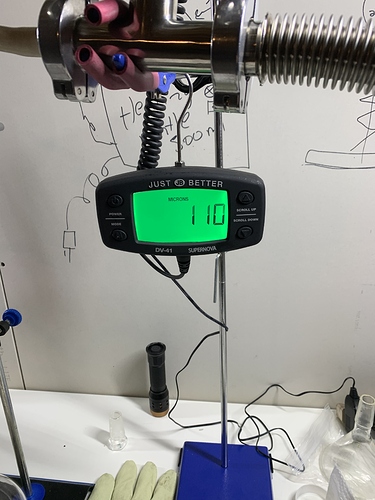

I lied! I removed the bellow hose and blocked it off the KF-25 to 3/8" adapter that connects to the pump. Its at 110 microns blocked off. I’m going to take that off as well and tape it. I think I forgot to, and see if that makes a difference. Otherwise, maybe I purchased the wrong KF-25 adapter/connector.

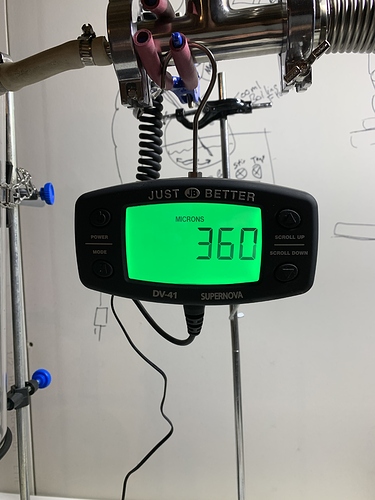

I’m at 145 microns, with no thermometer adapters in the still. I’ll cross that bridge when I come to it.

Yes the pump seems new and I would be surprised it doesn t hit whats projected

And rule of thumb

If it get s down great today

O well tomorow most likely it won t

Reason I often fill and close my rig the night before with vacuum on all night so I have no stress when I start

I moved the gauge from connection to connection, starting with the pump all on it own with nothing other than the KF-25 to 1/4 inch jic. The gauge read 110 microns. I then connected the bellow hose, then the Tee and tested it each step. 110 microns each time. Re greased and and added the thermometer adapters, I’m still at 110 microns. I’m thinking it’s the pump?

When I first started up the pump, I got 30 microns. Same exact test with the same connection, and I’m getting 110. Could it be the oil already? Or just the pump sucks?

What is the minimum amount of crude oil I can start with. I have about 30ml of crude that I have sitting around. Is that too little? I just don’t want to blow all my oil at once and ruin it. It gets me high AF in the state its in now (FECO/RSO).

Thoughts?

gauge or the fitting you’re attaching the gauge with would be my bet. It could be the pump, but my money is on the KF-25 to 1/4” JIC leaking at the npt interface. I never got around to tig welding one, but I did machine a JIC connector to fit a KF-25 that came pre-drilled for just such tomfoolery.

It would have to be the gauge or pump then, i’d rule out the fitting/center ring/oring. The pump has two intakes, one is a 1/4", the other is a 3/8". So the gauge fits right onto the 1/4". If I block off the 3/8" intake, I get 110 microns. Checked the gas ballast (saw that on a thread here somewhere). Can’t tink of anything else to check!

Like I said though, when I first got the gauge, I connected it to the pump in the same manner and was getting 30 microns.

Thanks for the ideas @cyclopath !

With 30g starting crude oil, you should get around 17g decent 1st pass. Even at 110 microns. If that will hold while running. There is a dry ice trick to get another -5 to -10 microns.

By the way, this is the most fun I’ve had in a long time!