restrict the exhaust* of the vacuum with a bit of paper / card

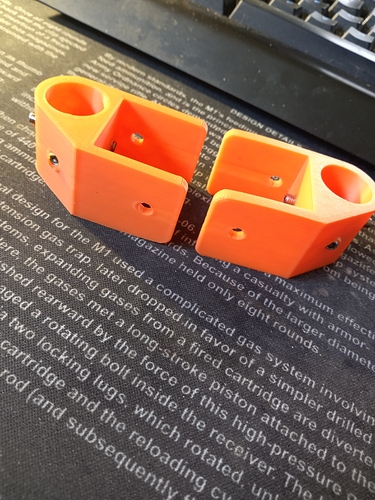

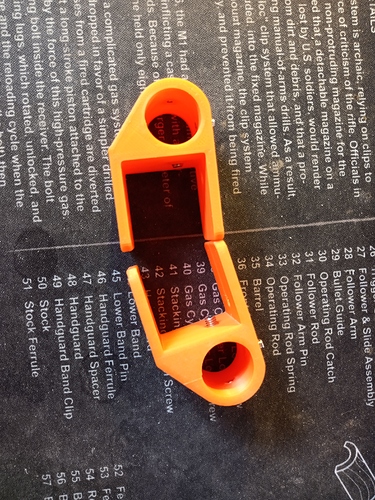

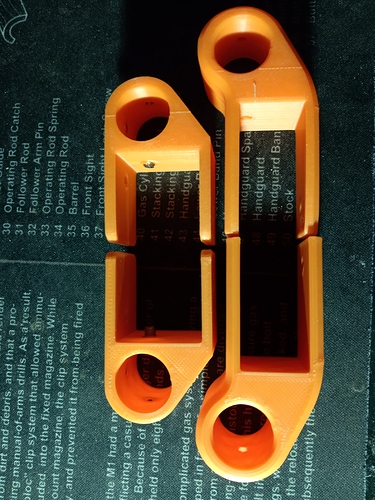

Worked a little more on the tent pole stuff today, printed these as testers. I’m gonna get some smaller grub screws/increase the thickness to prevent wear on the fabric of the tents, and probably offset the mount a bit to keep it from being in direct contact with the fabric. The screw hole closest to the pole needs to be shifted outward a bit in order to make contact with the wood, and it needs to be changed to fit the true dimensions of standard lumber. I can’t decide what thickness is best, but I feel like 3/4" is about the minimum

Changing the design to 4 of these at the corners instead of two larger ones cut the print time 75% and reduced the plastic used a good bit as well

Awesome to see what a little imagination time and programming can do. Top work lads

Got a little warping in these, but it’s about what I had in mind

19mmthickpolemount v2.stl (100.0 KB)

reminder!

last day for submissions!

I haven’t learnt enough yet !!!

oh shit, I forgot this was a contest lol. Too much fun making stuff

still got time boys!

Here’s the seed sorter files for mine, I added a 17.4mm hole for a 1/2" npt tap. I’m not gonna invest too much more time into it right now

seedsorterv1body.stl (206.3 KB) seedsorterv1frrontpanel.stl (22.2 KB) seedsorterv1tray.stl (5.4 KB)

Ok submissions closed as of now!

Good job to everyone who submitted models, and helped chime in on the seed separator design. There are a lot of extremely talented individuals here, thanks for making this place what is it. ![]()

So here are the contestants, let the best two win!

0 voters

@Apothecary36 got your seed seporator printing for the 4th time, this time bigger nozzle, heated enclosure, and aqua net hair spay. ![]()

![]() Thanks for the tips @pdxcanna!

Thanks for the tips @pdxcanna!

We will have round 2 soon, different prizes as well!

get your votes in before 9/4/20 ! winners decided on the 5th!

Ok so the big day has arrived!

First place winner is @pdxcanna , great job and nice contributions!

second place winner is @RockSteady , love the panda spout. your solids were nicely modeled.

Lastly I want to give and honorable mention to @VapeJet, I have a t-shirt for you!

Winners pm me with your shipping info!

Great job everybody who contributed drawings and added to our think tank!

If your going to put in the time on learning CAD than I suggest signing up to Autodesk as a student. You can download it for for free and use it for two years. I use inventor and plant. I actually started on eMachine shop at my early stages of trying to develop my CAD skills last year. I wish I never wasted my time on a less advance one.

Fusion 360 is what i downloaded because of @Soxhlet

At the moment i’m having a nightmare trying to make 90 degree connectors. Im trying to sketch a DIY cryo chiller, I have the cooling coil but can not change the origin so i can connect, either its because the coil needs to be its own component or im just smoking to much while trying to learn lllol. Give me 3 month … ![]()

Don’t burn yourself out in trying figure the software. CAD is one of those type of software programs that requires time to develop proficient skills in. Devoting only two hours a day is what I recommend.

Ok, youtube learning class 2 hours a day it is … ![]()

![]()

![]()

are you trying to mate 2 assembles? It sounds like you are trying to connect something with the start of a coil?

Yes sort of. I think…

Anyway. Scap the idea for now. It’s far too complex for my level of ability.

My new project starting tonight.

Two shafts that mesh together and rotate lol.

We will see…

Best way to learn any cad platform IMO is find some dimensioned drawings of parts and make them in CAD. There’s no considering the design so you can just focus on using the program

Haven’t been getting enough airflow through my tent, so I started on a baffle intake that slots into one of the fan inlets. I need to add a couple more baffles, seal it up and paint it, then figure out what the ideal filter paper is

Couldn’t figure out a good way to print in one piece, but I think this is elegant enough given the application