Update: warped again… blue tape…damn you! gonna go to my other printbed now!

try sheets of masking paper

or buildtak. Hairspray or glue stick on the bed works for me too.

I used some type of sealer for charcoal drawing for a long time with good results, similar to hair spray. Right now I’m using the purple glue sticks and they’re working fairly well.

I am going to probably make an enclosure too, see if that helps.

Used Aquanet for the longest time on a glass bed. When we switched over to PC from PETG for most prints we found that it no longer worked quite as well, so been using the purple glue sticks for a while now and it seems to work well with PC.

If going the hairspray route, my very unscientific study of about 10 different brands on AMZ says to use aquanet unscented.

Never had much luck with blue tape. Buildtak seemed to degrade too fast for constant use, but that was an earlier version. May look at that again if the purple glue ever stops working. However PC sticks to the purple like crazy, and releases easily after cooled.

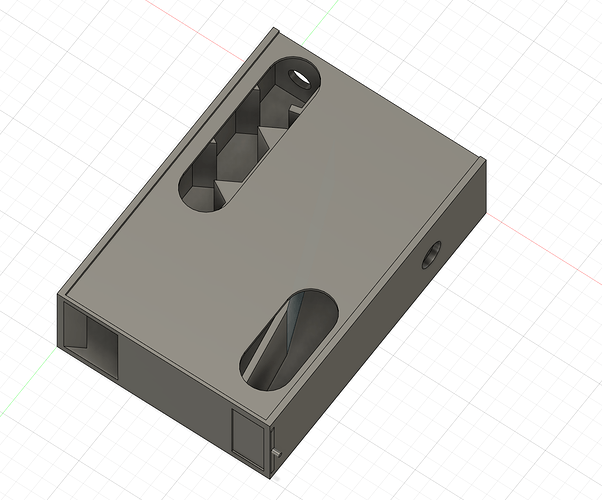

I made a printable front cover, I’ll just use some packing tape for the window slots for the time being. I’ve got it mostly cleaned up, the last thing at this point is coming up with something to connect the vacuum and adjust the airflow

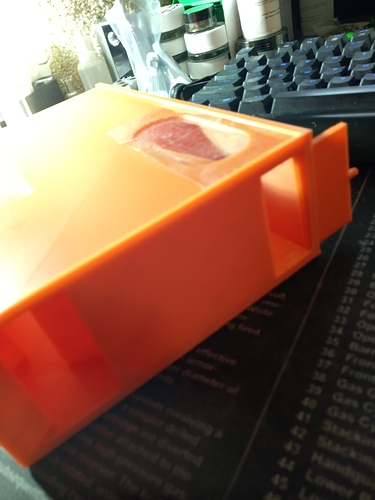

Got the first beta complete, gonna grab some hemp seed to test it with, I don’t have enough otherwise

As im from the UK i noticed the mat your woirking on . What rifle is it ?

edit :The seed separator beta looks nice !!

m1 garand tekmat, I use them as a full size mousepad. And thanks!

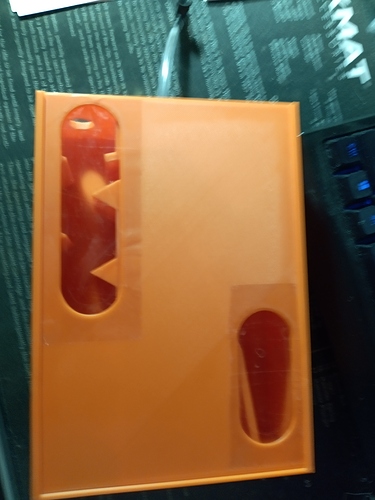

So, I just did my first small test and there are a couple issues to be sorted with my version. I definitely need to add a vacuum adapter, preferably with a mesh screen filter and a pressure regulator couple together. I’m thinking of something thru-hole that threads through the vacuum flange to the box interior, coupled with pausing the print to insert a piece of mesh into the print(or using an infill pattern, hex or cubic).

As it is, half the seeds I dumped through made it out the chute as intended, and the other half made it into the shop vac, not the bottom of the device. I believe another small piece of mesh glued in will help, between the vacuum flange and the lip that is I tended to divert leafy material downward.

The group on the left made it through as intended, the ones on the right ended up in the vacuum.

It’s looking like a solid concept, just in need of some turning. And I definitely need a better supply of seeds, anyone in the Portland area that wants to help/sort some seed feel free to chime in

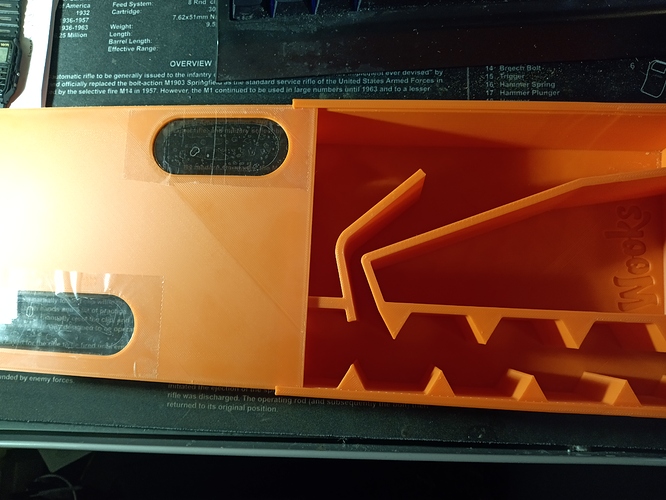

My suggestion would be to eliminate number 1, lower number 2 so it is a little below the ramp up, and increase the angle of the ramp into the second collection side. Also I would match the left side triangles to be the same size as the other.

Those are gonna be v0.2 changes, for now I’m gonna work with the existing print to see how usable this size is

This is a shitty mockup of what I have in mind

Hi,

I concur with @raghanded, delete the top leftmost wedge .

you also might want to put a larger bleeder in or do what @blackie suggested with the speed control on the shop vac. What kind of shop vac did you use?

the “1x1”, 1 gallon/1HP

Because the model is scaled down, the air “might be hauling too much ass” In my redneck opinion. Bravo to be the first one with a good print, I am going to re attempt tomorrow when my self esteem recovers! ![]()

Also as an idea, rather than try to restrict the vacuum or slow it down with a controller. Could you make a vacuum relief opening in the vacuum chamber ? So the vac still runs at full power but the opening controls the ultimate flow in the vacuum chamber ?

Hi,

normally people build these with vents and slider to “tune” the separator. I am doing a sleeve that rotates on the vacuum hose to control the bleed.

That was the intention of the aquarium valve, but in hindsight that’s more appropriate for fine tuning, I’m looking at adding a 1/2" npt valve for a coarse adjustment. A variac is also an option for slowing the vacuum still, but A/C motor speed control is tricky.

Right now, I’m on the same page as @soxhlet, I think a sleeve or valve on the vacuum flange/attachment is gonna be my best bet to dial it in

dimmer switch is cheap and easy.

I’ve tried using a basic dimmer for fan speed control before, they burn out in a couple minutes at anything below 90% power. The only thing I think would work is a variac, a VFD controller, or on the cheap end, one of those inline fan or router speed controllers