We use mastercam, it is like bashing rocks together to draw an object.Fusion is defiantly a powerful cad cam system as well, it also run simulations for strain and other factors. That is why we chose to upgrade.The only thing I don’t like the whole cloud thing, I like to air gap the computers I use for work.

Ok so running a 2mm wall and 20% infill, gonna be 43 hours on the print!

I just had a hard time switching from the very euclidean nature of solidworks. Having never really had to do any hardcore surfacing I just had a hard time with it but in reality fusion is much more powerful/user friendly for most product design stuff.

I only ran mastercam briefly but it is pretty nice as long as you have a good Post. Honestly, the CAM side is where I feel like Dassault is lacking. I ran esprit for a while and it made very nice tool paths but my fucking god was it far from user friendly.

Edit: I did also find fusion very computationally intensive/inefficient compared to other programs. I have a monster workstation that crushes FEA and can run nearly a million instances of SW but I still hiccup on fusion sometimes lol. I just don’t think it’s set up to utilize hardware resources as well

word!

oof, that’s gonna be nerve wracking waiting that long to finish. Mine’s a good bit smaller than yours and set for 10% infill, I’m slated for 16-18 hours on the Cura estimate. I’m about 3% in right now with a brand new roll of filament and feeling good about it so far

Ya thats about the size we built, once dialed there a great tool to have. That was my first step in trying to clean trim, ended up using a stand on vibrating exercise platform and different size hole fencing and worked like a champ

looking good!

This might be a good canadate for the MOARstruder and a 1mm nozzle!

have you ever played with large nozzles? Entire rolls of filament gone before your very eyes. ![]() https://www.lulzbot.com/support/lulzbot-taz-moarstruder-tool-head

https://www.lulzbot.com/support/lulzbot-taz-moarstruder-tool-head

Honestly, this is perfect for a shapeoko or MPCNC, I just wish I had the space to get some bigger toys. The 1mm extruder is pretty crazy, hard to imagine it being worth it for relatively simple shapes though

the advantage is print speed, although the object will look “coarser” as a tradeoff.

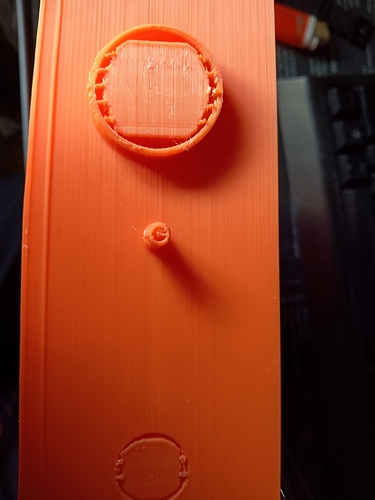

Well shoot the print had warped last night, I abandoned it and re sliced the model to print at 230mm/s with a fatter nozzle. I am trying to reduce the print time.

I got a little warping in the Z axis, masking tape isn’t ideal for bed adhesion at this scale I guess. It’s still a decent print and should be useable, but post-processing is gonna be interesting. Cura uses much denser supports than the creality slicer, some were easy to get out, but the stuff that’s thick or has a recessed feature is annoying to deal with lol

I’ll test it as soon as I can, I’ve got a handful of matching seed packs and some shake to run through it

That is what im running, shit let go last night!

I am printing it without support, your model looks like you could print it like that if you remove the top groove from any overhanging feature.

Everything but the little slide for the leafy material would be easier with no overhang, that piece is gonna be tricky no matter what, I can’t bridge that big a distance with no support. If the valve is worth a shit I’ll model a hole to fit a 1/2" npt tap, and I can remove the little flange for the vacuum easily enough

All in all, it’s a good beta though, I’m pretty happy with the design, we’ll just have to see how it holds up in real life use

got my fingers crossed for another 40hr on this one! ![]()

![]()

C’mon maskin tape be my friend,

Hold my print till the very end…

*to be chanted at the printer

Blue tape never did me wrong; print in quality petg; you’ll never have warping problems ever again. Also if you dont have a heated enclosure for your system look into a reptile basking light; aim close to the work piece; and keep it warm will minimize warping and defects.

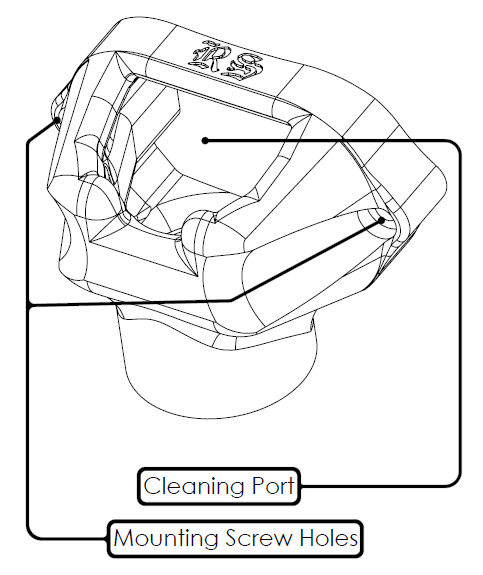

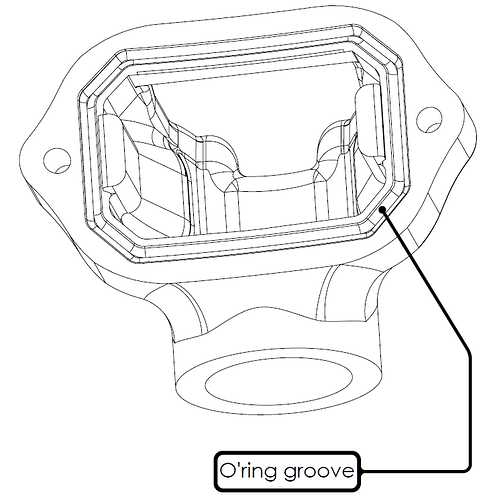

My entry to the contest is an older design i did; many of you already have one of these. early on when i was using pandas i was infuriated by the broken spouts; once the spout broke off the flow of recovered solvent was uncontrollable, messy, and quite frankly quite dangerous. So i came up with this design as a means to both control the flow the solvent and add a small element of “relative safety” to the system.

a year later i have sold over 300 units to labs on 6 continents; and i have to thank the community for the support in making this possible. anyways here are some images of the spout;

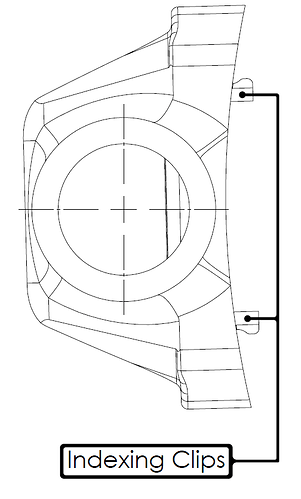

The unit indexes into the opening into the pandas sheet metal body via two clips; this centers the spout perfectly everytime so when you go to screw it in; its easy. There is an O’ring grove around the periphery of the spouts mating surface that helps assist in sealing. The spout was designed to be open ended; so that one could control the flow of solvent; but still be able to access to clear out any blockages. There is a spill way relief on the very front of the spout; the bottom of the spill way becomes the lowest point in the system so that you cannot flood the internal cup of the panda, and have solvent pour onto the motor. I hand tapped each unit(I dont trust 3D printed threads) sold; the female thread body supports 3/4" NPT threading for a polymer hose barb.

I printed my prototypes on my personal FDM machines; but printed the final versions of an industrial SLS machine; in a special chemical resistant nylon. The print quality off that SLS rig would blow your mind.

all in all 3D printing is cool af; been printing since 3d printing was a thing; i built my first FDM machine almost 10 years ago after i saw the early repraps release.

i wana get back to design; but chemistry hooked me in.

looking good! ![]()

Update: warped again… blue tape…damn you! gonna go to my other printbed now!