Love these ideas!!

Can the shop vac be put on a speed controller?

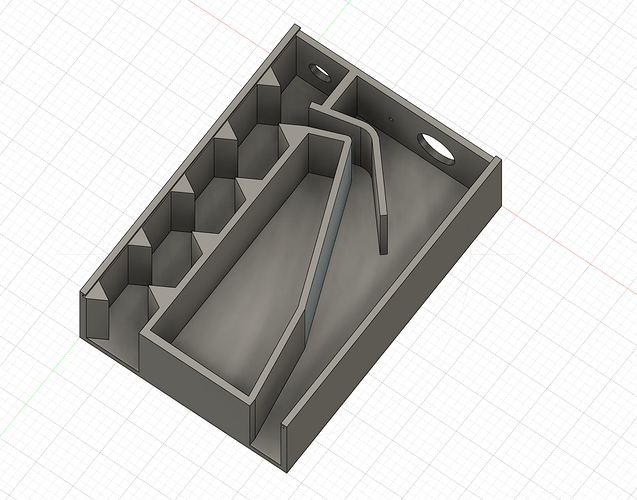

I made my own version last night just tinkering, I removed a bunch of the interior plastic to cut down on print time/waste, but it’s still around 16-18 hours at the lowest quality settings(.28mm layer height, 80mm/s print speed) and ~250 grams of plastic. I need to figure out something for the catch tray for the leafy material and probably put a stop on one end for the front plastic(sized for 2mm acrylic sheet, seems pretty standard). I’d also like to have a barb to attach the vacuum to, rather than have to place the hose into a female fitting

You can’t see the barb, but the small hole between the funnel/vac ports is what I was thinking to adjust pressure, but it’s almost certainly not going to be effective except for perhaps fine tuning

Hi,

that is a certainly an idea to control air flow.You could probably use a dimmer switch or a fan speed controller?

I can’t believe its not posted yet ![]()

3d printed kecks clips

SEED SEPORATOR.stl (578.2 KB)

So here is my final revision, I decided to relocate the vent holes to a collar on the vac hose.I also went the route you went and reduced the amount of material in the print.

stl is attached as well.

I’ve got a test print going right now for one of my revisions, I kept some material on the inside because I don’t want it to cause any problematic vacuum leaks. Mines a little different, but it should make for a decent WIP demo.

Assuming it doesn’t fail, I should have updates tomorrow

What are the dimensions of your model?

200x140x59mm

seedboxrevisedtestready2WOOKS.stl (209.8 KB)

no file is complete without the words “wook” lol!

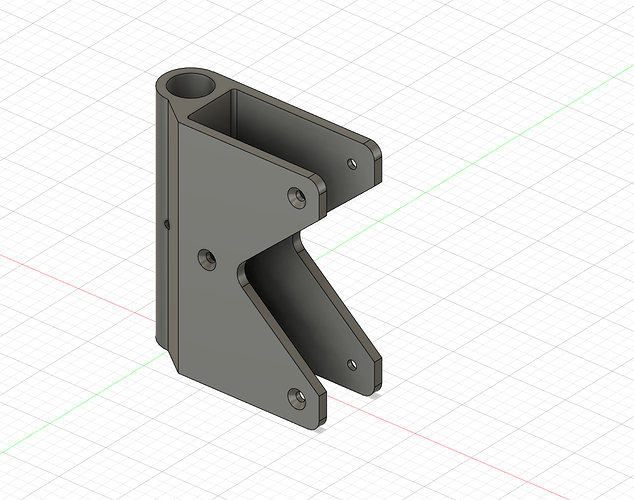

1by4polemount v1.2.stl (145.1 KB)

Made this for @Concentrated_humbold, fits on a standard grow tent pole and allows a 1x4 to be mounted horizontally for mounting oscillating fans, controls, etc. Uses #6 drywall screws for the board, M4 for the pole mounting screws.

edit: fixed a couple details that slipped by

Right ! That’s it … I’m going to teach my self cad …

I was trained as a manual machinist and can draw in plan, but never learned CAD …

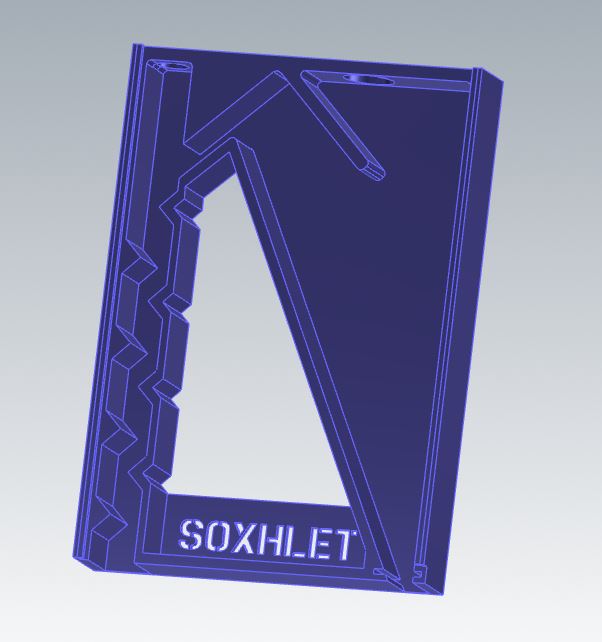

Will Sketch-UP do ? Or do i need to use AutoCAD the actual program ? @Soxhlet

Hi,

google sketchup works, fusion 360 works well too. We are going to switch from our current cad cam program to fusion in the next week or so. Fusion is free for the hobbyist, or student.

Excellent, i’m on it !

thank you

If you have any questions about drawing I can help you out.

In 30 mins i have drawn a 6" spool and assembled it to a component … It is ALOT easier than AutoCad was when i tried to use it years ago …

Now i need to do some youtubing, watch some people draw and yeah man, if i get into any problems i cant solve i will ask !

![]()

edit: I know what i want to finally draw. It’s a glycol chiller for butane recovery tank / vessel. I have a plan to make one using R-410A in the hope it will chill to -50c.

Instead of using the evaporator that is normally with an AC unit. I want to use the compressor from the split system and coil my own copper coil slightly wider than the diameter of the tank/vessel so that it can sit within the coil during recovery. Also im hoping all of my winterising can be done in the same collection vessel using this chiller.

( dry ice is expensive here and does not last to long for the amount of money it costs )

The cool thing about using a cad system is making assemblys, much easier than board drafting as well.

looks like you leveled up! ![]()

![]()