I used to dewax and run a coil and everything, then I did a rushed run one day as a test for the hell of it. Now I just store my material in space saver bags in the freezer, when it’s time to use I pack my tubes and store those in the freezer for a couple days with the ends capped. I also store my butane in the freezer always. Everything’s only at about -15F. I then pop the tubes on and run the tane quickly. 18-26% return material depending. Comes out fire. Just stopped over thinking it. I filter of course and it catches some fats but nothing crazy and I’ve dewaxed after and there wasnt much else

Sweet slabs, bro, they look fantastic! Do you flatten your slabs when you pour them? or do you have very runny soup when you pour?

Also, do you put a parchment on top of your slabs in the oven too? Wondering how yours looks so sexy flat like that.

Increasing surface area after your pour out does help achieve a “flatter look” but all shatter is usually glass thin. Thick shatter does not exist and if it did it wouldn’t be preferable because it wouldn’t easy to grab at or break parts off to dab.

Once again some wrong info.

Thick shatter doesnt exist? Straight trippin.

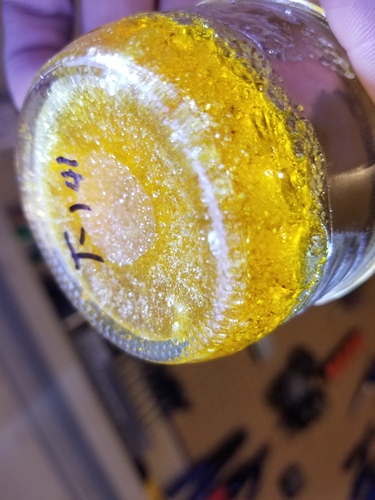

I have a slab that came out of a 1.9 vac oven shelf thats a little over a half pound. Glass thin lmfao ![]() breaks down just fine and is fire gold

breaks down just fine and is fire gold

What is your definition of that? Approximately in inches or milimeters please. Glass comes in all shapes and sizes so glass thin as a description in this case seems about as clear as paper. I’m guessing around 2mm-5mm range ~(80mil-200mil).

Seems thick is doable just takes much longer to process that due to the concentration slowing down the rate of solvent purging out. More goop in the way means a slower day.

yeah i was gonna say around the thickness of an extra heavy gauge guitar pick like 1.5mm 3mm

I think the only real “thick” consistency that is also flat is honeycomb or crumble. Shatter is preferably “glass thin;” I also think that if you’re making giant 1 inch thick pieces of shatter in a vac oven that come out testing clean then you have a strange and awesome tek no one knows about, is more what I was getting at.

I’m not trying to sound like a dick when I say, thick shatter doesn’t exist because the consistency is known for being “glass thin” and “like glass” so to say thick shatter exists would be absolutely redundant.

Thanks bro.

I pour my slabs when it’s fairly thick but when poured itll stop expanding to were it doesnt reach the parchment boat edges.

I think pull vac to 10hg right away until the muffin pops then in 5hg increments doing the same thing u till 20hg. Then let it chill till I can get it down in 5hg increment without spreading out too much.

It’ll have holes right away but then it’s still got enough tane that overnight itll fill in those holes creating a decently thin sheet.

As the days go on the holes form again.

When the slabs are done I hit it will a heat gun at a heat you can just stand to have on your skin with the more powerful air blow strength. I did this on both sides leaving it shimmery and not a dullness on either side.

This was the a slab from the round I finished the other day. Little more holes than i would like but it works for me.

I do not put parchment on top either. Do what I explained and you’ll get flat “glass” shatter.

This was the pinnacle of 2013. Swiss cheese was all the rage

Still is here I suppose lol

I forgot to mention an important part, to get the flat look, when your slabs are all done let them get down to 68°F out of the oven then put them back in around 92°F and let them melt back down for 35 minutes. Then do the heat gun deal. Thatll melt then out flat.

Im mean if its fire its fire

That’s what I think as well. Consumers like the swiss out here so that’s what I go for. Just answering buddies question on how I personally get it like that.

damn that’s quite a bit. I’m putting only 60 or so grams of extract per shelf on my 1.9. What’s the max amount of extract that you can fit on the shelf?

Pretty much what i said. Takes some finnesse and i have hit walls before on accident. So ya.

60 is low imo. A qp easily fits with no issue

Does anyone use any spreading tools? Im looking at crepe making to get me closer to consistent shatters and wondering what others are using if not pouring it while at an ideal level of viscosity.

I’m thinking one way is parchment could be used in conjunction with a smooth rolling pin, squishing small thick pieces into wider and flatter pieces before cooling. It would work depending on what point in the purge you applied said technique, say, before first flip when it is no longer too soupy/sticky. If too sticky at room/working temps then chill in a fridge/freezer before removing the extra parchment. Something to try on my next batch.