Most underrated comment on the forum here for you shatter nerds. This is the second time @NorCal has dropped this knowledge and it gets over looked because it’s so simple

I would assume this is best done in a dry air conditioned room…

never use a heat gun around butane vapor unless you wanna end up like those nutsacks in NM who were heat gunning while pouring off in a closed room. if you dont have ventilation you shouldnt be extracting in the first place!

I’ve also said this a numerous times. That’s how you melt and purge stable slabs. The mor flip the more stable. The more flip ‘n’ melt, the more Swiss cheese look. Been doing this for many years now. This is all done to look cool and be crispy, and obviously it is going degrade yourself extract a tiny bit. But if you need something with that consistency, this is a great way to get there

@midsfactory When you say “The more flip, the more stable” do you mean in the oven? Only flipping once a day, then put under vac again. If I increase the amount of flips during the oven and vac procedure, I can expect a more stable shatter? Yeah, I have seen the Swiss Cheese happen with the flip and melt with the gun, which also has helped stability big time!

Thanks again guys!

@Maple_syrup

Yes. Flip, then into oven, and vac. I do it every hour. I remember reading a skunkpharm thing (can’t seem to find it) about analyzing the gasses that come out of a oven (between oven and pump). They said almost all the solvent comes off in the muffin, then after that it’s mostly moisture and volatiles that comes off - and right after the flip.

Could be wrong, but it all seems to work good for me. It doesn’t turn sap into shatter or anything, but it can help turn something semi-soft into something semi-hard ![]()

Oh my, I lol’d at this comment while also recognizing how serious that truly is and yeah, if you haven’t thought 3” in front of your own face as to how you may explode it, you should probably pick a different hobby or career hahahahaha

After reading the chat here, I have made a purchase ![]() I wanted to just confirm the order of the equipment. This only makes sense to me, so it might sound dumb but would like confirmation if that’s cool.

I wanted to just confirm the order of the equipment. This only makes sense to me, so it might sound dumb but would like confirmation if that’s cool.

- Tane Tank

- Desiccant Sieve

- Cooling Coil

- Material Column

- CRC

- Honey pot

The only issue I see with the cooling coil is that the tane will get cold but by the time it travels down the material chamber, it will lose its temp quite fast and by the time the tane gets halfway, it will be back to a higher temp. I’m running a 4" x 48" material column. I can see the tane hitting the top of the column nice and cold but losing it’s effect with every foot of movement as it travels down. Would it be best to also add the material tube that has a sleeve loaded with dry ice?

Also, would it be a better idea to add a ball valve at the bottom of the material column to load up the material column with the tane and let it sit in there a bit to get to the desired low temp?

Thanks again for the info guys, as I will be implementing the ideas and answers provided ![]()

Don’t you guy’s know all you need to do to get shatter is cut it with Chios mastic. It’s the “speciall proprietary blend” used by in Extractor here in Oklahoma ![]()

Damn. I thought u only dewax for 15 min if ur running a cold tank. An hour seems long. 2-4 hours way to long I’ve never got stable shatter dewaxing for that amount of time

I don’t dewax at all. those were in the earlier days

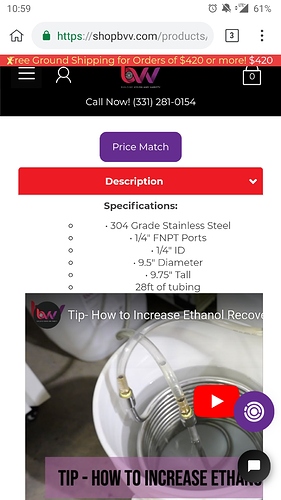

What type of fittings are those on that coil? can’t say i’ve seen them before.

Spot on, the details finally showed up on the site. I’m out in BFE so my internet is all heavily throttled verizon “4g” (2g at best).

Their site does that to me too, even with plenty of data figured I post a screen in case!

But it’s good for your health and has been used for thousands of years, right? just as long as you vaporize it at really high temps and coat your lungs with the “plant stabilizers sugar” ![]()

Glad someone saw it. “You cant find negatives about it”

So, I totally had a question about your dewaxing. When you injected into the dewax chamber, was it an open jacket with a dry ice slurry?

What’s up man. Yes when i did it it was an open jacket with a dry ice slurry

So, I was thinking of why that could have happened.

When you injected into the dewax chamber with the slurry in the jacket, your solvent recovered on the walls of the spool. In turn, releasing the initial injection, which is also the thickest, until the solvent started to fill the chamber up. Sound like that may have been the culprit?

When I transfer over, once everything is pretty much over, then I will start to chill.