Well said @greenbuggy.

Haven’t read the manual…but only because I’m not running anything that big yet.

Thats on the to do list, so I guess I need to read it now…

Well said @greenbuggy.

Haven’t read the manual…but only because I’m not running anything that big yet.

Thats on the to do list, so I guess I need to read it now…

Thanks for your feedback. We always appreciate positive critics as this helps us to improve our products.

You are in good hands now talking to Michael, we will get this right and for any kind of support you have our contacts and phone numbers.

Great post Greenbuggy, stick to your guns man.

Last year I bought a 6" Pope still and the instructions/documentation looked like it hadn’t been updated in a decade. Even had that old school type of binding they had in schools back in the day. Needless to say it was completely inadequate and didn’t even mention how to operate several of the features I had paid a lot of money to add to the still.

On another note, I found a company called Mydax that has a line of chillers called CryoDax that looks like it might be useful. They are big industrial units that have large cooling capacities in our desired temp range. Google Cryodax and their page with all the specs/pics should come right up. I believe they’re made in SoCal as well. I called them last year to ask about the CryoDax 8 which has 8Kw coolling at -40C, and I think it was around 50K. For reference, their biggest unit the CryoDax 120 has 60Kw cooling at -40C.

I believe that technology is called direct expansion cooling

Hello greenbuggy,

I am the Product Manager for Thermonics chillers. We specialize in large capacity low temp (-80C) chillers. You can get information on our web site at www.thermonics-chillers.com, or email me at sales@thermonics.com

I enjoyed your rant on Huber ![]()

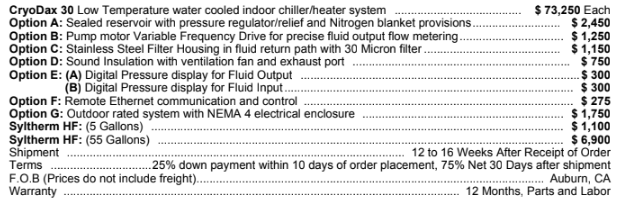

Cryodax 8 ~$50k

Cryodax 12 ~$55k

Cryodax 30 ~$80k

From quotes from the past week or so.

They make pretty serious units, at pretty reasonable price points, at least if their spec sheets are accurate. Probably what we’ll be using if we don’t find something that fits the cost/capacity equation better.

Wow is that price for the CryoDax 30 correct or is it supposed to be $180k? If it’s really $80k that seems like a great deal. @Lincoln20XX

That unit has 16kW at -40C and costs $80k.

For comparison, a Huber Unistat 915w has 8kW at -40C and costs $100k.

That’s not a typo. If they actually meet their spec they appear to be the best value/money option out there for high power chillers, at least that I’ve been able to find.

Thanks for post.

You need to compare apples with apples. The Cryo Dax has 20 gallons reservoir, compared to 25 kw of cooling power that is a pretty bad ratio. So most of the cooling power is wasted to carry the own load.

I can offer less KW system with much better performance. The energy consumption of that CryoDax is high . Last but not least 12 month warranty speaks volumes. We offer 3 years on controller, 2 years on the rest.

If you are strictly buying kw’s you are on the wrong trail , you need to start buying cooling power and performance.

But the Huber is getting the job done and we offer 3/2/2/ years warranty

16 KW of cooling power on 80 liters of volume that’s 200 watts per liter cooling power.

8 Kw on Huber with 5,2 liters of volume that’s 1500 watts per liter cooling power

Me too ![]()

Forgive my ignorance, but I don’t know a huge amount about the inner workings of chillers. Why does the reservoir capacity matter? Wouldn’t you want a larger (within reason) reservoir of coolant to limit the delta between the fluid that is leaving the chiller and the fluid that is returning?

Hello Sir,

no , you want a large surface area, a pretty good flow and a small ( lean ) internal tank

That what provides performance and speed. In fact this was the breakthrough in chiller designs back in the 80’s by Peter Huber, founder of HUBER.

Compare it with a 600 Hp Truck , which is heavy and a 300 hp sports car. We know which one is faster.

We have case studies on our website and we beat Julabo , Mydax and Lauda any time with less Kw’s.

Do you have a link to the case studies?

yes Sir

please let me know if you have questions

In my mind a larger internal tank only changes the speed to reach your target temp, but wouldn’t really effect the overall cooling power or efficiency. A large tank=temperature stability, a small tank=rapid temp changes. Seeing as how we use these chillers for one purpose (either low or high temps) then the bath size is not very important. In fact pair both heating and cooling is not important and seems to only raise the price. We are throwing major heat loads at these so we need the 600Hp truck, not the 300Hp sports car.

I hate to state the obvious but investing in a colder freezer would take a lot of stress off your chillers. I’m not sure it’s the solution but it’s something to consider.

We have actually invested in a larger walk in to store bulk quantities of ethanol at well below ambient temps. Unfortunately the readily available walk ins tend to max out around -20F and the ones that get down to -45F or more appear to be anywhere from $60-100k depending on size and cooling power.

I’m not going out of my way to throw Huber under the bus here but I feel like an update is probably in order and it doesn’t entirely paint Huber in a positive light. One of our 815’s that was working started throwing codes for a temperature sensor and a tech from Blackhawk Industrial came out and did some work to it. Less than a week later it refused to cool a single reactor to below -10C with no load. Needs to be sent back to Huber in NC.

Huber has a sales guy working with us to see if something else would work better for our application that we can trade our 815’s for/towards. Having retooled our production line and no longer using the Hubers to cool down larger quantities of alcohol, we’re just using the 2 functional 815’s to keep reactors cold and deferring the bulk cooling to a large walk in freezer. To maximize our production using existing equipment we need a single chiller to keep 2 reactors cold and I think that’s asking too much of a single 815 (we have 6 reactors we’d like to have running at all times to get the maximum production rate).

Still haven’t heard a peep about fixing our problems with the Spycontrol software and the Huber website still shows the exact same files as when I downloaded the buggy software months ago. For the forseeable future I will be doing production temperature logging with a different piece of hardware.

I think if Huber wants to get more units sold to our industry Huber really ought to sell something like the Unistats with more cooling power between -20C and -50C and no heating. And fix the datalogging problems.

I think looking at different chillers by comparing their heat transfer capacity in the needed range with their price is apples-to-apples. I’m willing to concede that there may be some variance in standards used by different companies to make the ratings and certain aspects of reliability come into play.

I understand that, in a nutshell and simplified, the Unistat technology principle means using a mostly standard fluid chiller without a reservoir combined with your particular electronics and pumps. Eliminating the fluid reservoir minimizes heat transfer fluid volume in order to increase the system’s speed of response, which is first and foremost on the list of advantages to the system in your company literature.

Given that info, it’s not surprising to see you using words like “wasted” and “bad” when critiquing your competitors’ fluid reservoir size and citing the watts per liter of thermal fluid stats.

I need to condense light hydrocarbon mixes at a high rate, so I need a cooling system that has high energy transfer capability at -42C. I don’t really care how long it takes to get there or if it’s super precise, within reason, as long as it can hold that temp under operating conditions.

Given that starting criteria, I don’t see how the fact that the 915 has a fast response rate, or “better performance” as you put it, makes up for the fact that it has half the energy transfer capacity at -40C but costs $20k more than the Dax30. It might be the right choice for other processes that require precision temp control over raw cooling power, but not this one (passive recovery), IMO.

What is your definition of better performance? Unless better performance somehow translates into more cooling power (which would be reflected in the cooling data), I’m not sure the cost:benefit ratio of it makes sense for passive reocovery.

I have looked at the Huber literature and the closest unit to the CryoDax30 in terms of cooling capacity seems to be the Unistat 635w with 18kW @ -40C and 25kW @ -20C. I found a listed price of $220k, almost 3x the cost of the Dax30. I couldn’t find the amperage info, but I’m sure it will require close to the same 60A input as the Dax30, if not more.

Being that you are the owner of the company, I understand that you believe you can offer more value to us through quality of construction and other things (your warranty is great), but from a strict cost per cooling capacity @ -40C standpoint, your costs are pretty high. Even if the reliability is through the roof, if I can buy two and a half Dax30’s for the same cost as one of your comparable units, I’m going to give Dax a shot, but that’s just me, others have way more money to spend.

I’m really not trying to be negative here. I think your chillers are precision instruments and the Unistat technology enables them to ramp up and down in temp quickly. This along with your advanced controllers allows complex temperature programs to be ran and accurately repeated. The cost of the units reflects the R&D you’ve put into that. IMO, you make precision scalpels and we need a blunt machete.

Also, I have looked through several of the case studies on your website and they seem to be displaying the performance curves of your chillers hooked up to different sized reactors, nothing showing you “beating” Julabo, Mydax or Lauda with less Kw.