That company should give me commission for posting that

that is true but im pretty sure the jacket fittings and rack mounts are machined and fabricated here. as they dont come complete from china. so the vessels are still sent out else where to get completed…

I meant that, as well with the columns. But, you are correct. Wasn’t wanting, or needing to go into great detail. Just wanted to emphasize that the large vessels are the only ones mostly fully made over there.

Oh I know you probably knew that and didn’t necessarily mean to direct that towards you. More just for the others reading !

Busybee is one of the options we are considering, what is your general impression of their systems?

high quality.

Well, not too many really know about us just yet… Check out Illuminated Extractors for the latest in extraction technology. No CO2/LN2/expensive chillers required. +50c to -50c in minutes. Low power consumption. Single column to ten column units available. Patent pending technology.

@Killa12345 had great systems that are built and designed by an extractor @Killa12345 himself

You should work with @Graywolf to make an automated terpinator ![]()

![]()

How are you chilling?

I actually am studying mechatronics in collage for the past while, already working on doing all the automation, this thing will be far beyond what is currently on the market, fail safe systems along with programmed protocols. pre programmed extraction parameters, ability to save recipes. Logs saved of what the sensors picked up during the run. Oh and a butt ton of good old exact repeatability.

you seen the Luna IO?

It puts the Cannabis in the tube, & then it walks away again

Easy enough to do controlling pressure and time.

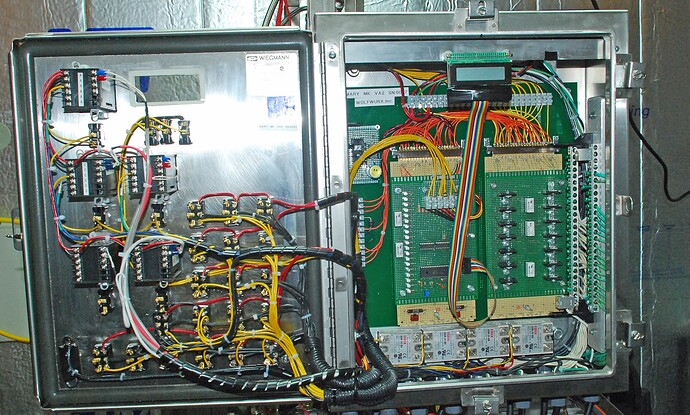

The Mk II Terpenator was automated using a programmable controller, as were the Mk -VA, and the Mk-VA2’s using a chip which we had programmed. Circuit boards by PSI and control panel by Moi.

The Mk II and Mk-VA used pressure switches and the Mk-VA2’s used a pressure transducer to track the process. The program activated air solenoid valves, which controlled pneumatic ball valves.

Been a minute since I posted that. We modified the machine to have 2x3’ columns so we do 4-6lb runs on the machine. We also added the carbon scrub after the collection.

It’s funny how much BHO you can supply on even a small setup like this.

I think I saw this at NECANN… the only downside is the price.

I could be wrong but I believe he told me somewhere around 425k

No drill thru there is a pass thru fitting u use. Maybe look at titan fittings. They have all sorts of compression fittings. Ur gonna want a double ferrel compression

I disagree with @420guy

once the fitting is welded into the lid, drilling it out is superior to replacing it.

I’ve got fitment so I can clamp stuff down on the mill, and @TwistedStill was kind enough to slip me the required tooling to turn the mill into a BIG drill-press. I don’t recommend freehand.

if the fittings are not yet welded in, you can absolutely buy them bored through (add BT to the Swagelok part number), or do it yourself. although there the recommended tool is a lathe, rather than a drill press.

There is actually a pass thru fitting available. That part maybe a pass thru union or something?

Im not a metallergegist not sure if boring it out does anything to the intergrity of the piece? If its froze down low or something?

Prbly a 30$ part im guessing

Mustv missed the welded to lid part? Lol

Sawgelock is expensive. I usually use titan fittings cause cheaper. I havnt had any issue wirh their parts.

not a reader either…

the manuracturer refers to them as BORED THROUGH

https://products.swagelok.com/en/c/straights/p/SS-400-1-8BT

you can also bore them your own damn self.

No, OEM does not “bore them out” at this point.

No, don’t do this freehand.

yes, so long as you’re not touching the taper the ferule interacts with, or heating it up to a million degrees because you’re boring with a blunt instrument, you can safely perform this trick in a machine shop near you.

I read just fine as i dont pay for over priced sawgelock unless i need it same day.