I use a Milwaukee packout box with drawers, very nice for the money to haul tools around. Top drawer is electrical:

Fluke meter

NC voltage tester

Tic tracer

Assorted tapes and connectors

Spare fuses

Batteries

Next drawer is screwdrivers and pliers:

Wera lasertip screwdrivers and nutdrivers (these are awesome, especially for soft screws)

Linesman’s and needlenose pliers

Box cutter

Knippex channel locks

A rat tail and half round file

Allen wrenches

Tape measure

Label printer

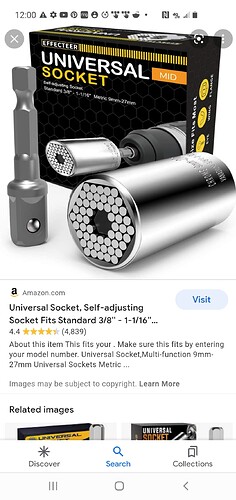

Third drawer is sockets - 1/4" to 1/2" drive, deep and short, plus Allen head, torx, and etorx

Fourth drawer is tube fittings:

A shitload of spare swagelok fittings, ferrules etc plus some assorted MP/HP stuff

Rigid tube cutter

Deburring tool

Stone

Set of punches and cold chisels

A couple standard size drill bits/unibits

Pens, grease pencils, notepad

Next is rachets and drives/extensions/adapters

Last is wrenches: one metric gear wrench set up to 24mm and SAE up to 1". Three spud wrenches (also hugely useful). A ball pein hammer and a set of 12" dial calipers

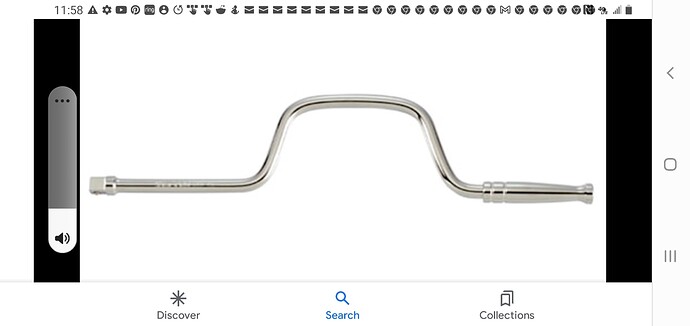

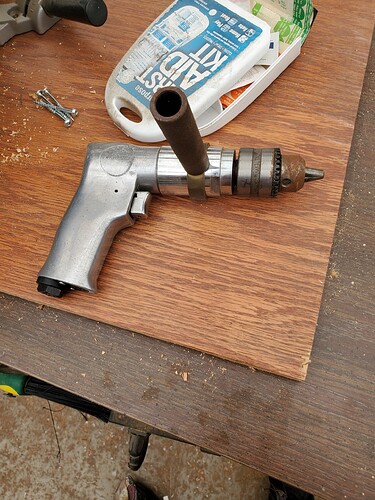

In the bottom I keep a tube bender, kit of assorted stakons, o ring kit, hard grease, tap grease, antiseize lubricant, drill/impact (I like the small Bosch set for on site work), and a bunch of spare solenoids, relays, relay timers, 24vdc power supplies.

That about does everything I need to service an 80ksqft grow and our extraction/production labs. At the end of the day I probably put the whole kit together for $3-4k which is less than an equivalent size snap on tool box lol