Been having a problem with my vacuum levels, Ive checked everything, every little connector, got rid of all my rubber tubing replaced it with silicone, even went out and bought a brand new Welch 1400 pump brand new out the box thinking it was my pump causing the problem, but vacuum is still not going below 1200 microns, its fully stable no fluctuations, Ive been pulling some immaculate product I’ve posted a video on some first pass. I’m starting to think it’s my vacuum guage that might be the problem. I’m really confused at this point, I’ve been pulling material at extremely low temps so I’m quite sure my vacuum is stable with no leaks, I’ve fiddled with connectors to see if my vacuum fluctuates but nothing, I fiddled with every single piece of connector and glassware but no conclusion. I’m hellbent on seeing my vacuum gauge at sub 100.

What’s your mantel temp when pulling main fraction? THC or CBD?

What kind of shortpath do you have?

Let’s see a photo of your thermo probe adapters. That’s usually the worst leak.

Sometimes my first passes take place at 1200… Have you done a 2nd pass?

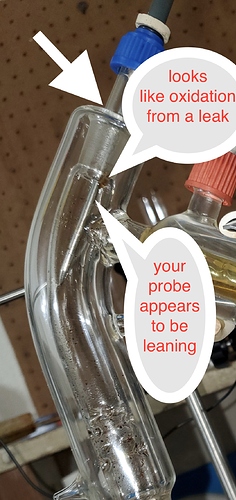

My mantle temp is roughly 205C-210C on the mantle when my first fraction begins, Terps come in at around 170-180. I have a 5L boiling flask, I had a suspcion that it was the probes however I took them off and placed the glass flask covers and still the same exact Vacuum pressure. Heres a picture of them anyways, I purchased custom O-rings to keep the probes from leaking nothing beats O-rings.

Have you connected your vac guage directly to your pump to see what its ultimately capable of?

Yes when I direct connect it vacuum goes down to roughly 100 microns it keeps going down by increments of 5 but it takes way too long, Welch 1400 are know for taking a while.

Have you done a 2nd pass?

Have you tried pulling a vac on an empty system?

Yes I always do a second pass vacuum levels are almost exactly the same never above 1250 never below 1200 microns. My material comes out flawless but I’m just entirely confused on the vacuum levels, I just cant get over the vacuum problem it baffles me

Pulling on an empty system it went down to 400 microns one time and it kept going after I added material in vacuum went back to 1200. I avoided touching anything made sure my cow was untouched in the process.

Get yourself a helium tank at the baloon shop

Let you vac pump run on a closed system for 30 min

Then spray helium gas over the joints

Slowly making a cup around with one hand

Keep an eye on the gauge

If it starts flipin numbers you found the leak

That thermo probe. Joint can use more Grease seeing those horizontal lines

To me means to little grease

You can also spray warm alcohol or acetone on the joints.

Yes i head that one from a other member but never tried it

Yust warm liquid with like a windex spray ?

Did you vote ?

As long as all your joints are greased, pull a vac in a heated system. While looking at your vac gauge, start at the bf temp probe, and go down the line on every joint, looking for any vac changes. If the vac level jumps around at a certain joint, theres one leak.

How old was the starting material? How did you get to the crude needed?

That pump is also way under powered at .9cfm for a 5l. I would run at least an alcatel 2021 bare minimum, i pull mains for 1st pass around 170-80 and finish at most 210 with a vac below 50 for first and below 10 for 2nd

You could try putting a stopcock in place of this thermocouple and see if your vac leak issues stop. IMO it’s likely the culprit

How do you know your material comes out flawless? Do you have some lab tests showing your cannabinoid levels? The first vid the fraction looks cloudy, pulling heads still maybe? Try plugging the thermoprobes and running it. But that pump is wayyyyy undersized for a 5L

Thanks Brother I’m going to give this method a try will le tyou know what happens. Its honestly the first time I’ve ever heard of that helium method. I tried the candle method where you bring light a candle near the connections and joints to see if theres any pull

Welsh 1400 will not work for a 5 liter unit

I got a test done a while ago just to ensure I wasn’t wasting my time and to make sure it was good to try, I’ve had this problem for a long time now even on my old 1400 it did the same exact thing. I even bought a large rebuild kit , cleaned the original down to the vanes! I put it back in my system same vacuum depth. Went out and bought a brand new pump still same vacuum. That fraction looked cloudy because it was a first pass. On a second pass its completely transparent