why dont you like Cmeps? i get they arent the best, but ive had good luck.

Couple of reasons - first is that they like to advertise this pump as being an oilless unit but they have a lousy crankcase design with greased bearings that absorb butane when the pump is under positive pressure, when the pump goes under negative pressure at the end of the recovery cycle the grease boils and blows out the seals on the rod bearings, which can contaminate your butane stream & causes the bearings to fail prematurely. There’s workarounds and better bearing options (with either ceramic bearings and/or a PTFE based grease less susceptible to blowout) but the pump didn’t come with either of those options from the factory.

It’s not UL listed and no inspector that is paying attention would allow it to be installed, & the way it comes from the factory, a rubber SO cord with a gland strain relief on one end and a normal household plug on the other does not pass muster for either C1D1 or C1D2 explosion proof standards, typically a proper install would use an end to end XP/Hazloc rated conduit or flex conduit to a disconnect outside of the extraction/hazloc room.

QC is lousy, you’ll want to double check tightness on all fittings since half will be loose by the time it hits your doorstep. Several users have complained about leaks at brazing spots where the gauges are located. As a person who does some machining I’m not impressed by some of the fitup and surface finishes on multiple parts.

I think the CMEP is not a terrible deal for its cost, but at significantly more money than the TRS and other pumps I don’t know it if justifies it. If you have the ability to provide enough air to run it, the Haskell is a far better option, and if you’re using this kind of pump daily I’d seriously be considering a Blackmer, MVP or similar grade pump that pressurizes the crankcase with an inert gas to prevent butane ingress.

Is there a thread about cmep rebuilds with the proper bearings to fix that issue ? I’m about ready to attend a rebuild.

I don’t know if there is one here, I think there’s a couple on the ICMAG forums, I just know that what most are selling as “replacement” bearings are just standard 6908-2RS bearings, most aren’t even 6908ZZ with better quality metal seals on them to do a better job of keeping the grease inside the bearing where it belongs. FWIW 6908ZZ are like $12/ea on eBay. I know Ecogreens site says theirs are packed with PTFE grease but I haven’t actually ordered a pair yet to verify if they have special grease or ceramic components to justify that. From the pictures on their website they appear to just have the 2RS style seals. https://ecogreenindustries.com/product/bearing-s6908hc/

I have lots of old gear i dont use anymore if you want it. Haskel, cmep, mvp, several tricked out gc5000s

The numbers on the bearings is all you need. There $20 on ebay and then have different versions like ceramic etc

I ran 4cmepols before the mvp and haskels were so popular m, also didnt have to space for the compressor needed to run them. With just 2 and running only crude i was get a lb per min with nust ice water pumped through a heat exchanger. I had really good luck with them i lnow alot havent but if tou go that route get the gen 3 they have the prv for the crank case so they dont have the same problems as the previous ones. Also depends on what you intend to run i was all crude so hot and fast and thise pump ran 10-12hrs a day for 2 years before bearings went out and did a full rebuild which is pretty simle just need to know the few tricks to getting the apart

We got one. How do I see if it’s gen 3?

It bas no radiator or fan and theres a bress prv balve on the gottom of the crank case. Dis ou buy it ised? Rhe liquid cooled radiators for the gen 1&2 check out exo greens website so you’ll know whay gen you have and if you end up getting one of the liquid cooled radiators worklike a champ and are super easy to install

It’s brand new

This is the gen 3

no radiator or ran and has the pressure realeaes valve on the base gen 1&2 are basically the sameYa that’s not what ours is unfortunately

If your going with Cmep make sure you get a wax trap before your pump. and put the pump higher than your outlet of your cls. If your close to ecogreen they are good people and Nicole will tell it how it is. The bearings do go out buttt if you keep up on mainteince with top end rebuild gaskets than it will last longer. I use to run it everyday. I it’s safe and really have to drive into to the ground for it lockout on you. Just listen to your pump you will know things are different. Attend a rebuild course and don’t go balls deep trying to rebuild it if you haven’t done one before. . It’s a tricky beast and your dealing with flammable gases.

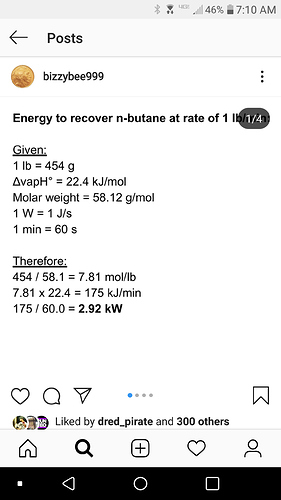

I run a dlsb 30/80 from touch science for chilling my recovery tank and run fully passive 30lbs of solvent over 5lbs material with crc in less than 5 hours. Lots of people Will say this chiller wont do this but I have been doing it for almost a year now with no problems. They make a dlsb 50/120 that would be even better. Also there is a formula for figuring out exactly how much power it takes to condense butane to liquid at a given rate. I think I saw it on bizzybee Instagram. Works out to something like 3.14kw of cooling power for 1lb per min. Keep in mind that a chiller power rating is like a horsepower curve and isn’t equal throughout the entire range of temperatures.

And there it is, choose your chiller based on this math and enjoy the peaceful sound of no recovery pumps

If anyone is looking for Haskells I’ll have 3 of them for sale in the near future.

We’re getting a Corken.

Xtractor Depot has them for $2,999

In my opinion, CMEP and TRS21 are both okay for recovery, but their outlets run hot which scares the piss out of me.

I just bought a brand new cmep gen 3 with a condenser built in hoping to reduce pump noise and cool the outgoing gas stream.

The CMEP-OL has terribly low displacement at 1.25CFM for what it costs. Also, the CMEP-OL uses a non-articulating piston design and has a very weak piston ring.

The non-articulating piston design causes side loading when the rod is at it’s steepest angle which distorts the piston ring allowing vapor to enter the crankcase and cause problems. CMEPOL pistons/rods

The manufacturer even recommends replacing the piston rings every 6 months, that’s pretty terrible. This pump was rushed to market around 2015 and IMO is a terrible value for the cost.

The TR21 also has low displacement (no spec found) but has an articulating piston and a much better piston ring design. Not to mention a much cheaper price. These are what I currently use and I have had good reliability for multiple years from them. TR21 pistons/rods

To me the cost difference of $650 for a TR21 versus $2500 for a CMEP seals the deal by a mile.

I’ve been bull shitting passive with BizzyBee forever. I think that post was because him and I were talking for two weeks figuring out which chiller was best for passive. And I spurred him to post a whole bunch of stuff about boiling points, vapor pressures, and the energy needed for recovery.

I still hate cmeps. Shop stools at best. Hvac guys can use em. If I had to, I’d put a bunch of trs together like d00d said in the beginning, with a small mol sieve after for all the bull shit they spit out.

DUDE! You sound like you know what you are talking about but you have quite a few factual errors.

The CMEP is UL Listed, there is a sticker on top of the motors.

I have tested all sorts of ceramic bearings and none of them last. I do not recommend. That experiment at my shop cost me over $5k in warranty work.

PTFE grease vaporizes at the operating temps of the pumps and makes a poisonous gas.

Factory bearing is a custom made 6908HC with a generic seal.

I have worked on over 500 CMEP’s in the lsat 3+ years and have never seen a leak at any of the welds.

People rip on the CMEP because they do not have their systems set up properly and run liquid through the pump. If your rig is set up properly, you run proper temps, you will get 600+ hours minimum before needing a comprehensive rebuild with bearings. . That being said you still need to do a top end rebuild about every 150 hours, takes about 40 minutes or less when you get fast at it. . If you fail to do top end rebuilds, you are likely to have gas get into the case.

Another problem people have with the CMEP is they do not use the custom, high temperature bearing that is supplied from the factory. Regular bearings will only last about 40 hours before failure. I have seen these cheap bearing being sold by companies that sell CMEP parts as an option.

I rebuild over 150 CMEP’s a year. I have lots of people that are VERY happy and it is because their systems are set up properly and I use factory parts. I am a factory authorized and recommended repair facility.