I hear ya , im on disability , hobby guy, my budget dictates more than I’d like, excited that 2020 will be positive growth

It’s all hobby for me as well, so any cash I drop there’s no money coming back.

Plus, I figure what money I save I can put back into my rig.

Heating pads work hreat also they dont get hot enough to worry about and in a pinch there at the drugstore. I always kept my sieve warmed definitely helps

I have one of those elctric heat pads and have thought of using it , buuuut I’m not really wanting and electric device and a column of hydrocarbon vapors, I can def up my safety game in a few areas, but not trying go booom ,lol

Although I am looking into the silicone heating tape options to wrap my sieve, the hypocrisy of myself! lol

All about how you stage the filters for dewax… from SS mesh down as far as you want. the more stages the better filtration and less change of flow issues or clogs!

@Curious_Roberto there may be no money coming back but every dollar towards improving your system and quality of meds is a great investment!!!

Got the circle one

I knew there had to be a better way lol

Thank you sir

I’ve been using a 4’ aluminum straight edge and a utility knife.

I fold it up, and make a small cut on edge of the folded felt, making sure I got through all the folds, where I want to make my 6 foot long cut. Then Unfold it. Now I have little cuts, like a spaced perforations, to guide my scissors across the 6 foot length. It works, it’s not ideal.

This is actually what I’m going to be doing moving forward I think though.

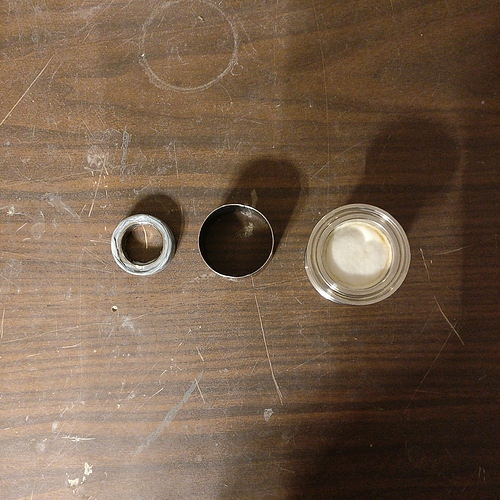

I found a leather punch that the od of the spool. I don’t think we need to much depth, so now I can punch of a few layers of whatever size I want, I have 25 down to .5, then I take one of those rings you made me and wrap some teflon tape on it until it’s tight, push the filter discs down, then use the ring as a retainer.

I think it might work great. I have a step down filtration, and I’m not using nearly as much material as before. I don’t know if the filter depth needs to be super deep.

Fucken A…I know a machinist that can make a leather/gasket punch…he’s made a few before. I’ll pass the idea along to him…I just did…and he’s going to have to make some.

Great idea @Curious_Roberto.

I like how it rolls up and stuffs in my spool so tightly, but I would also like to be able to take the sheet and use it, singly ply if you will, in other places on my rig

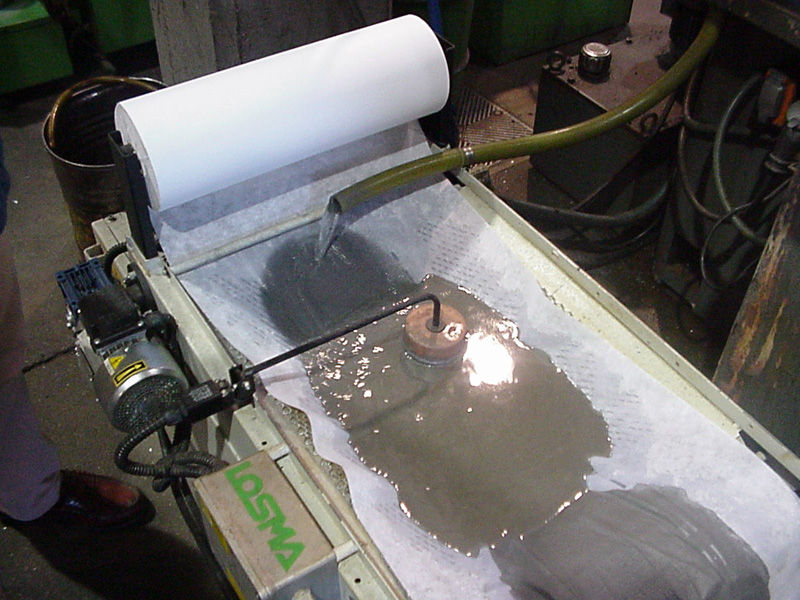

Its funny…I’ve been walking by a pallet of felt filter material, in sheet form, every day for 8 years. We use it to filter grinding swarf out of the coolant in our CNC grinding machines. Now I’ve got my eye on it…the stack may start getting smaller…

I got a super cheap set on Amazon for 7 bucks. If you want the bigger ones, they have em on etsy.

I like the rolls too, but I was looking at their site and the flow runs perpendicular to the felt. I’m wondering if running the flow along it has the same filtering effect. Probably NOT, but just got me thinking.

Plus if this works, the sheets I have will last an eternity lol.

Edited to add a not above.

Man, you got ahold of that machinist friend quick!

After meeting you yesterday, I can now read your sarcasm beautifully.

Ah man, I’m jelly you guys got to meet!

I’m super odd. If you meet me…the way I type on here will make a little more sense lol.

Yes, the flow is supposed to go perpendicular to the plane the sheet creates when flat. Its filtering characteristics are not at all the same when rolled up and flow is parallel to the sheet. But, with it rolled up, your creating the filter…the depth, in my mind, makes using this felt in an incorrect manner acceptable.

I use it for my last line of defense in my filter stack and can reuse it over and over until I fuck up and get powders on it during disassembly lol.

Application where I work(taken from google)

I’m trying to use the felt and screens as my main filtration. Figured if I’m using it as a consumable, might as well try to minimize my use of it.

I’m gonna try doing a 100 micron gasket, then 75, 50 screens under my material spool.

Then for crc, I’ll pack the celite above a 25 micron screen, under that I’m thinking of using 3 layers of 25, 10, 5, 1, .5.

Hey man, you from Holland? Have some questions about cbn

Yep tell me what are the questions ?

Ik wil echt een eigen CBN olie merk gaan maken en ontwikkelen. Mijn kracht ligt in het vermarkten en groot maken van merken. Ik zoek dus echt een product kenner en iemand die voor mij het proces wil en kan uitleggen om CBN te maken en eventueel op grotere schaal te maken. Samenwerken is een optie. Sta eigenlijk voor alles open.