Hello all, wanted to pop my posting cherry with something I haven’t really found much on.

I run through brass bolts for my tri-clamps pretty frequently, just from wrenching them down so hard every time I put my system together. It feels unsafe, but I’ve been just replacing the nuts every couple weeks, and the rest of the clamp assembly about once every year, I’d guess. Is there some basic entry level info i missed about how to precisely tighten your clamps without any leaks? A few years ago when I upgraded to the teflon gaskets, I had to start tightening even more. I recently had a friend visiting the shop, and the squealing drove him insane.

Possibly a torque wrench, or maybe an air wrench? Is this just the way it is???

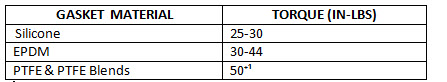

Each style gasket requires different torque specs to prolong gasket life and make seal right… You shouldn’t just tighten the crap out them

Welcome to the forum!

I’ve had the best luck using a torque wrench on the brass nuts. This ensures an even tension across the bolts and really helps with leaks. Speak to your CLS manufacture and ask about the specific ft/Lbs you’ll need to set your wrench to, this should help extend the life of the nuts. They are however a consumable and designed to wear rather quickly, I’d recommend replacing them often as you have been even after purchasing a torque wrench. Hope that helps!

Awesome, thank you! Would you say that the actual clamps also frequently need replaced? I had read somewhere a while ago that they may get warped over time from torquing, but it almost seems an impossibility to me.

Hey! I’ve been using the same clamps for over 5 years. The nuts and bolts get replaced every year or so. For gaskets, it depends on the material. For clamps we are taking on and off constantly (collection pot/material column), I prefer viton because they require less wrenching. Generally, once you hear the squeak, you’re probably good to go. I’ll usually give it one or two more turns once I hear it. They don’t need as much as you May think. Also, you can always test this with air pressure.

Dang, 5 years strong. Yeah, I’ve already got an air chuck coming through the wall for other stuff, and recently got a head for it that i can attach to the top of my loop.

Another reason I’m more concerned now is that I ordered parts from a different manufacturer, and the gaskets they sold me are THICC. the 2" tri-clamps (originally from bhogart, but now trying to fit them on OSS spool and gaskets) actually don’t even fit over the joint. The 4" and 10" fit just fine, but I’m considering getting new clamps. Bhogart here in town has thrown me under the truck more than once, but it’s so much easier walking into a brick and mortar - IF the parts are compatible.

I’ve personally only had to replace clamps when I jacked them up IE dropping heavy things on them and causing dents and dings. Just keep any eye on the points where the bolts contact the clamp for any unusual wearing, but most will be good for the lifetime of your CLS.

Convenience is a hell of a drug!![]()

I’ve only over tightened one brass nut to the point where it cracked.

I usually tighten until it squeaks 2 or 3 times. Also make sure the bolts are the right length

not til they crack, but the threading does wear down with time. it was a bigger issue when i was doing tear down and rebuild 8 times a day, that’s when i got in the habit of just having a sack of brand new nuts on deck.

One of the most common errors I see with systems is overtightening fittings. The most common offender I see is over tightened compression fittings. Many fittings do not require hulking them for a proper seal. As @StoneD and @WolfeXtracts have pointed out, there are more often than not specs for those fittings which should be available, and a torque wrench may be a great asset to your toolbox.

Hi @_lee

The best way to stay safe is religious use of a torque wrench, I never operate without one. Now i know alot of people don’t like to use one, but i find it as easy as using a ratchet with this model.

Now a word about gaskets, due to the difference in size and materials used there will be a difference in the required torque value required to seal the union.

The best gaskets we have found are called envelope gaskets, they have the best chemical resistance with a ptfe outer envelope and a springy viton core. This allow a lower torque value to compress the gasket fully. pure ptfe gaskets suffer from incredible plastic deformation and only will survive so many cycles before needing replacement; however, they are great for the odd seals that you do not regularly take apart.

Basic procedure for making a sanitary union should be as follows:

- make sure both surfaces are clean and free of dust and debris.

- make sure your gasket is clean

- place gasket between the two ferrules

5)inspect the clamp and bolt assembly for signs of wear and fatigue, replace worn components - apply the clamps around the ferrules and hand tighten the bolts and washer assembly.

- set your torque wrench to the gasket manufactures recommended torque value, and torque the nuts evenly,

- with a wooden or plastic rod strike the outside of the clamp firmly to break any stick-tion and settle the clamp.

- re torque the nuts to verify that they haven’t become loose from the clamp settling. This phenomena is most seen with the 12’’ triclamp.

Hope this helps

-sox

Thank you, both @Phytoalchemy and @Soxhlet. Looks like I’ll be picking up a torque wrench this weekend!

On the beer production side it’s customary to spray some star san on both ferrules and the gasket. Thoughts?

Gaskets are an expendable item, should be changed out regularly to ensure your system is air tight! I use PTFE/Viton gaskets and I get about a month-6 weeks(depending on how much live resin I process) before the viton starts to slip out of the gaskets, Tri Clamps themselves should last forever , although the Bolts and nuts can strip over time from over tightening or just regular wear!

Truly can’t stand envelope gaskets…always prefer solid…many years experience with both. For vacuum…torque spec is useless…they will leak unless cranked down tight…real tight! Envelopes will deform and leak.Best advice is to use a Teflon paste on the clamp threads to keep them from galling and “squeaking”…squeaking means you are galling and ruining the clamp. I use a Swaglok product called Swak, but any quality PTFE paste will work. For pressure your torque specs are OK, but I still go way over that to get a vessel to pass a helium leak rate check…vacuum or pressure. Hope that helps.

I believe the squeak is from the pressure washer cutting into the nut, but I could be wrong. I also use the squeak method to know wen to stop.

Where do you guys source your hex nuts from? I can only seem to find the 3/8 threading brass nuts and nothing with a larger threading for heavier duty clamps. If someone could point me to a good source I would be in your debt.

I had a lot of trouble sourcing them back in the day, but now Open Source Steel and pretty much any other system manufacturer has them available on their website for pretty cheap.

the squeak method (but it drives nails into my ear drums), and letting the system sit under vac with a gauge while it’s being chilled for an hour. I have enough ball valves in-line that I can even check multiple chambers or spools off of the same gauge.