My room is about 65f and my tank sits around 80-100.

Lets say we use an 091 at 7.4 CFM, 100 psi inlet, 200 psi outlet, 50F inlet… that puts you right at 7lbs per minute with propane. That is really pushing it. The cooler the inlet gas at pressure the more volume you move. Once you correct the m3/kg @ inlet temperature of 50F, you will see how 5-7lbs per minute is possible. Which in reality, the compressor never runs at full or minimum speed. They typically land closer to 2/3 to 3/4 total speed to save on cost and maximize efficiency.

Abso-lutely

Yes:pray:![]()

![]() Austin was good people

Austin was good people

He truly was a warm individual to meet as an earnest young man fascinated by a wide open world of extraction.

Our system is completely different than the traditional cascade refrigeration system similar to the iced tech chillers. Those units are not much more than a low temperature multi-compressor multi-gas refrigeration system connected to a heat exchanger. It requires well more than twice the power to perform a fraction of the work compared to our design.

We provide a single stage refrigeration system that can get down to temperatures much lower than -70c without the need of a cascade refrigeration technique utilizing multiple refrigerants and compressors. Our Behemoth model typically sees roughly 25kw of cooling capacity at -40c using only 10 amps to maintain as was recorded during our prototype testing phase. Room temp to -50c in 5 minutes typically.

Any plans on selling that refrigeration unit?

This already exists… Most are late to the party for some reason

Appreciate the semi detailed response! Thank you and I am very excited to see how this thing does in the industry. Will keep my eyes peeled for it!

As it is the refrigeration system comes standard with our extraction systems for the initial roll out. We do have plans to make a stand-alone unit in the up coming future, though I cannot say when this will happen.

Please keep me updated if you ever roll one out.

I did not know there were butane membranes in use. Any examples? Curious to see the results!

Was my understanding as well. Everyone I know of using membranes are either ethanol or maybe heptane / hexane. Typically utilizing heavier weight solvents that are liquid at atmospheric pressure.

I feel propane is the most advantageous due to its natural vapor pressure and density / viscosity properties.

I know one person who is using membranes for butane and they’re keeping it close to the chest (I don’t know what elements they use). I have experience with using them in liquid alkanes only.

Interestingly, the pressure of the typical membrane process is above to critical pressure for hydrocarbons – so with heating, supercritical membrane filtration would be an option. I have no idea what sort of effects would occur from doing that, and it would certainly need a lot of layers of safety.

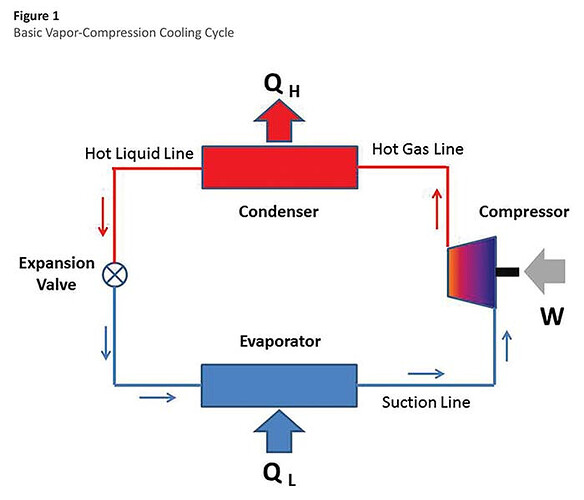

If I’m following correctly, it sounds like they’ve taken the middle-man (chiller) out of the temperature changing situation. A refrigeration cycle works exactly the same way (including using Propane!) but it’s used to usually cool a chilling fluid which then is applied to your vessel, as opposed to chilling it directly with the propane. In case everyone forgot how a chilling cycle works:

In most cases with traditional chillers, the Qh is simply lost as heat rejection from the chiller itself. It sounds like our friend here developed a neat way to utilize that heat rejection to boil solvent and then turn around and recondense it with your Ql heat value. If you keep your propane within the 2-phase region between saturated vapor and liquid, your temperature remains constant as well.

My two cents if you’re running straight propane in the jackets of those columns, for the love of God please make sure it’s properly pressure-rated (I saw on the website that they are ASME-stamped) in both the jacket and the vessel, and you’re using proper components for the compression/expansion cycle. The vapor pressure of propane at room temp is roughly 120psi, not 50psi like I’ve seen thrown around a few times.

It’s also very interesting that the recommended operating temperature (-40c to -50c) also happens to be the saturation temperature of Propane at roughly atmospheric pressure. ![]()

Yeah it does require special columns for sure and yeah we have taken advantage of the Qh/Ql values in many ways. That is not the main component of what makes our tech special but is a factor; the Navy has done this for many years. Energy recycling is nothing new.

References to 50psi std condition is stated for what certain compressors expect under inlet conditions, does not mean that is what propane will be at when stored in a vessel without vapor being removed.

Our -50c reference is just a baseline in 5 minutes… the temperature drop does not stop there. I have taken it to -106c with current design and with a simple modification I think we can hit -120c or lower as a single stage refrigeration system.

We have also recently ditched all heaters on our systems along with expensive chillers, CO2, and LN2 thanks to our Patent Pending refrigeration technology. There are many approaches to the same result. Efficiency is going to be the focus of the next wave of extraction technologies.

All of our systems come standard with a 50 state Pressure Safety Inspectors certification!

The membranes I have been looking at all show to operate within our typical extraction conditions and so long as the flow rate matches up, we shouldn’t have much difficulty. Pre-filtration is quite important with membranes. After that - filtration is filtration. Pretty simple stuff honestly. Molecule size to pore size.

We should have a prototype going in the next couple of weeks. Gotta go train in Oregon on a Turbo Unit here next week but after that membrane filtration will be our primary focus.

You’ll find with some experiments, it’s not so predictable. But you’ll certainly get good results with some effort.

Oh I know… just like with all filtration. I definitely don’t expect the first filter to do all the work. There definitely is a need for pressure control to force certain products into the permeate vs retentate…

I am honestly looking forward to it. Our system is pretty much designed perfectly to have membrane filtration added onto it.

There’s lots of subtleties. But you will get there. It will prove a great addition to any BHO system. I am working on it myself.