About a million bucks.

Mechanical seal, we do them for mixers.

what is the rate of recovery, and the solvent to material ratio?

I’ve always found the high capacity claims interesting

Can you explain what’s going on in the machine? I talked to your sales guys at a few show pre covid and could never really wrap my head around it.

How many lbs of solvent does it hold?

At 100 lbs an hour with a 5 to 1 ratio is a lot of lbs of solvent recovered. Me thinks the cannabinoid laden solvent is doing passes through multiple columns but again I haven’t got the slightest idea how this thing works.

I’m very interested in historical yield data

It’s a couple of teslas less than that

I can do this with my current purge set up. So there claims aren’t far off, it just takes 2 more people

The Behemoth extracts and recovers at a rate of 20-30 lbs per minute depending on conditions using propane. We only use a single injection of 75lbs for an entire day of extraction and typically see a 1-3% loss.

Our systems operate quite different than other units available on the market. The solvent ratio is simply time based. For instance, a 12lb column at a 1:10 ratio would take just under 5 minutes to extract when moving 25lbs per minute. No extra solvent other than the initial 75lb injection is necessary. You do not need nitrogen with our systems. Crude is removed throughout the day while extraction processes are taking place via our GD1 evaporator.

We typically fill a 55 gallon drum in about 5 days. Technically a single person can operate the Behemoth once you know the machine well enough, until then we suggest 3 people on the machine and 2 packing socks. Loading/unloading columns is the most time consuming aspect.

no butane?

do you experience yield loss?

Our certification covers butane, isobutane, and propane and any blend of the three. When using 100% butane in the system the rate is just over half the speed of 100% propane as its vapor pressure is much lower than that of propane.

We suggest a 70/30 blend that is propane heavy to maximize on extraction efficiency and recovery rate.

If you watch THIS 2019 Youtube interview (or search their name and look for the vid by Taddy Digest) with an Illuminated representative at a tradesshow and go to 1:05 into the video he says that the Behemouth costs $800,000. I’m sure it would be more expensive now since this was years ago.

Even better, in the same video at :48 seconds in, the same representative says that the Behomouth can run 1000 pounds in 6-8 hours. LOL.

And I’m still dubious about his current claim of 100 pounds an hour (1000#/10hrs). I mean, it might be possible with enough workers just to hit the number to say you hit it but it’s not ideal or sustainable day after day IMO.

Also, don’t dismiss the fact that he recommends 5 employees to run the Behemouth. Last year he wouldn’t say how many it took. If you’re a business owner that’s a lot of labor to pay for just to maybe get through 1000# into crude per day.

Who in their right mind is gonna want to extract 1000# per 8hrs everyday by packing, unpacking and then cleaning 7-10# socks continuously?

IMO for making crude on large scale you need a process with larger material holding vats than a 6" column, this generally goes hand in hand with using a lower volatility solvent.

I think this high-labor way of making crude you’ve presented is not efficient and most people who know what they’re doing and want to enter the crude production market would do it with a higher throughput, lower labor solution that is probably much cheaper as well.

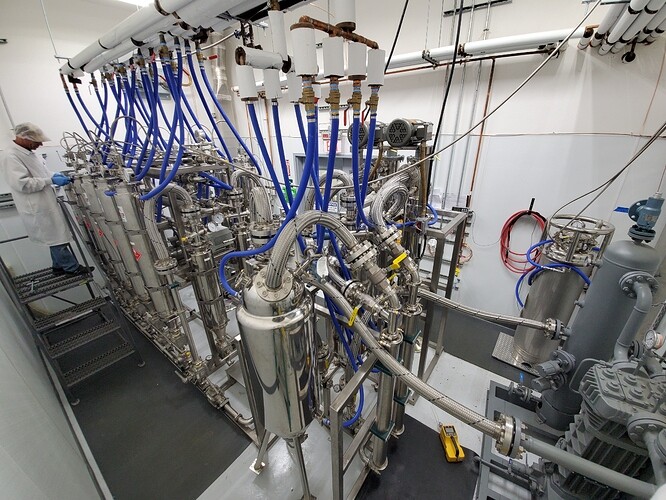

Take a look at the pic below. The uninitiated might look at this pic and say, “Wow, so cool, so fancy. I would be a king if I owned that!”

To me this is way overly complicated and much too expensive just to make crude.

I think propane/butane recovery is the wrong place for a wiped film evaporator.

It sure is fancy and jangly though, probably expensive too, but of course you can’t find a price anywhere.

A wiper is generally used when you have thermally sensitive compounds that you are trying to distill at the lowest possible temps. Since the compounds are sensitive you want to distribute them in as thin of a film as possible to facilitate the the gentlest boiling possible.

I hear you, “But Tech1145 we DO have thermally sensitive compounds!”

When we are recovering with propane, as this system uses, the solution temperatures will never even come close to temperatures that would thermally degrade our compounds. Even at a collection side pressure of 100 PSIG the solution temperature is only 65F (16C).

This fact really makes the complication (rotary bearing and electric motor+controls) and extra cost of a wiper vs a FFE (tube-in-shell) really unnecessary.

A tube-in-shell heat exchanger setup as a FFE would be a much more cost effective and simpler solution that fits better with what we’re trying to accomplish. A tube-in-shell offers much more evaporative surface area over a wiper.

Speaking of this subject, I don’t believe I ever got a straight answer from you last year about this quote of yours talking about your wiper vs a FFE:

Care to explain this little gem again? I believe you said something about the wiping action creating more “effective” surface area when compared to a FFE. I’d love to hear it.

This guy was on here last year talking about a SUPER secret, patent pending “tek” that of course he wouldn’t explain outright on the forum, you had to call or email him.

Care to explain this “phase transient” solvent in a little more detail?

A saturated vapor is a vapor, plain and simple.

A saturated liquid is a liquid.

It sounds like what you’re trying to describe is a saturated mixture meaning saturated liquid and vapor in equilibrium. The percentage of the mixture that’s liquid or vapor depends on the conditions.

It’s definitely not a unique state of matter like you are trying to describe it.

Lol. Phase Transient.

I’m sure the Chad’s eat that right up tho.

The website also mentions something called High Pressure Hydrocarbon Extraction which of course is capitalized, acronymed and has the little “trademarked” symbol next to it but you can’t find a single word actually explaining what it is or how it works.

Care to explain that one? Or should I call you?

Hmm, where have I heard this type of “thermodynamic wizard” rhetoric before? Seems common in the Chad brands.

If the basics are so head smackingly enlightening, why don’t you just explain them to us instead of giving us the Chad routine and making us call/email you?

$800K for a crude machine that takes 5 people working to maybe achieve a measly 1000# per 10 hr shift while having to continuously pack/unpack 10# socks is completely outrageous at this point in time.

Have you seen the throughput-to-cost ratio on some of these newer large scale membrane skids? Or even just a scaled up bucket tek?

One could spend not too much more and get a system that would do 2200# per hour and spit out a distillate type product and a hydrocarbon style terp fraction. Or isolate, if that’s your jam. With the same labour requirements or less.

Using gaseous hydrocarbons to make crude is… Special.

![]()

![]()

![]()

![]()

![]()

![]()

Did someone say scaled up bucket tech?

https://www.instagram.com/p/CPq-524hN6y/?utm_medium=copy_link

130 pounds an hour with a maytag washer and my 2 in 1 membrane skid

Wait till I get a Screw press

when not running crude but something like live resin or dry cured for topshelf - is the solvent condition in a liquid state or still “phase transient” (which i take to imply a 2phase fluid)

Jesse was a fairly new employee at the time of this video and is no longer with us. As for the machine, we now include our on-demand thermal control system at no extra cost. On the Behemoth, it provides roughly 25kw at -40c and can cool a column from room temp to -50c in 5 minutes and maintain with minimal amp draw. We essentially re-invented the air conditioner to be much more efficient and is patent pending.

As for our 100# per hour, this is at a 10:1 ratio. Most people run a 3:1 to 5:1 ratio so we are going a bit overkill.

You have definitely been very opinionated now and in our previous conversations, maybe you should come check out the machine and run one before you make such statements?

We typically have bins of socks on hand for daily operation. Thinking that we are packing and unpacking the same socks while running the machine is absurd. You have to clean them in between uses.

The overall complication of operation is strictly to the user. You can have the mindset that it is hard and for you it will be. The overall operation of the system is quite simple and it pretty much just runs itself.

As for our wiper, we have discussed this before and maybe you should re-reference that thread? There are a ton of reasons why the wiper is the right choice in this application and you are again making assumptions.

Physical wiping action provides an increase of surface area by agitating the molecules at a set speed. Anyone who has ever ran a wiper knows they are faster than a tube-in-shell system. Agitation increases the exposed surface area thereby increasing the recovery rate. This IS basic physics. Really simple stuff to understand. This is no different than stirring to increase the rate of dissolution. You are increasing the effective surface area by mixing at a set speed.

Now we get back into your understanding of solvent physics and the real world of solvent physics. Do you still believe a superheated vapor can be partially liquid and still be considered superheated? Its easy why it is not put in clear words for you: we don’t want our processes being replicated by everyone such as yourself. Come talk to us and we can go from there. I will let you in on some of the High Pressure Hydrocarbon Extraction™ details. ![]()

We are aware of membrane skids out there and are starting to incorporate such tech in our designs.

For those who understand basic physics, a liquid is a liquid and a vapor is a vapor. When you transition from a liquid to a vapor it goes from 100% liquid to a % of liquid and a matching % of vapor (that adds up to 100%). As the liquid transitions to vapor the liquid becomes mixed with vapor in proportion to the amount of transition. Going from one phase, such as liquid, to another phase, such as vapor, creates a saturated liquid-vapor mixture. Because it is in transition from one phase (liquid) to another phase (vapor) it is “Phase Transient”. This is an extremely old reference you are quoting but it stands to be correct still today.

I would be happy to hear of another company who uses a saturated liquid-vapor mixture as part of the extraction systems design? This is part of our patent pending tech that literally eliminates the need for spray heads / solvent misters / atomizers / etc. The solvent is instantly turned into an atomized solution as it passes through the extraction column. ![]()

Had the same lid i made for my maytags backnin the bubble days, get a boat hoist itll make holding those bags easier

I have seen the posts you make of the green crude coming out of your membrane system, nothing too special there.

Fully condensed compressed sub-cooled liquid at -40 to -60c for live resin. Our refrigeration tech is the best!

Funny my crude tests higher then yours does on your behemoth even when cold extracting

You forget your lab in Fort Collins sent me some of the crude off your shitty machines to work with

It wasn’t even winterized and it was ran on your behemoth with the cold jacket

I wasn’t knocking you but if you want me to

I’ll post test results of his crude vs mine since this dude wants to make claims that aren’t true