THE FOLLOWING IS NOT MY WORK BUT IT’S IMPORTANT HISTORY. THIS WAS WRITTEN BY GRAYWOLF.

6.9.3 The History of the Terpenator According to Gospel

Success has many fathers, while failure is often a bastard child, so stories abound about how closed loop BHO extraction got started.

Truth is also shorter than fiction, so let me share my perspective to consider with the rest.

I didn’t invent the concept, but instead got my inspiration 07-26-2009, 06:58 PM

from a 04-26-2006, 08:13 PM post on IC Mag by Foaf, about how he used two paint pressure pots and a refrigerant recovery pump to extract cannabis with butane and recover it for reuse. It was entitled BHO Large scale closed system and can be read at: bho - large scale closed system | International Cannagraphic Magazine Forums

6.9.3.1 From that I conceived the Mk I:

And built this prototype, using a such a deal bargain oil less refrigerant recovery pump.

Here is the lineup for show and tell pictures in my kitchen. Shown here with the 48" column, made from Schedule 10 304SS pipe, with 4 bolt ANSI flanges that I had machined for an o-ring:

But alas, the pump was defective as received and Ricky’s Bong turned me on to the Appion, shown below in the a pilot run using a 24" column.

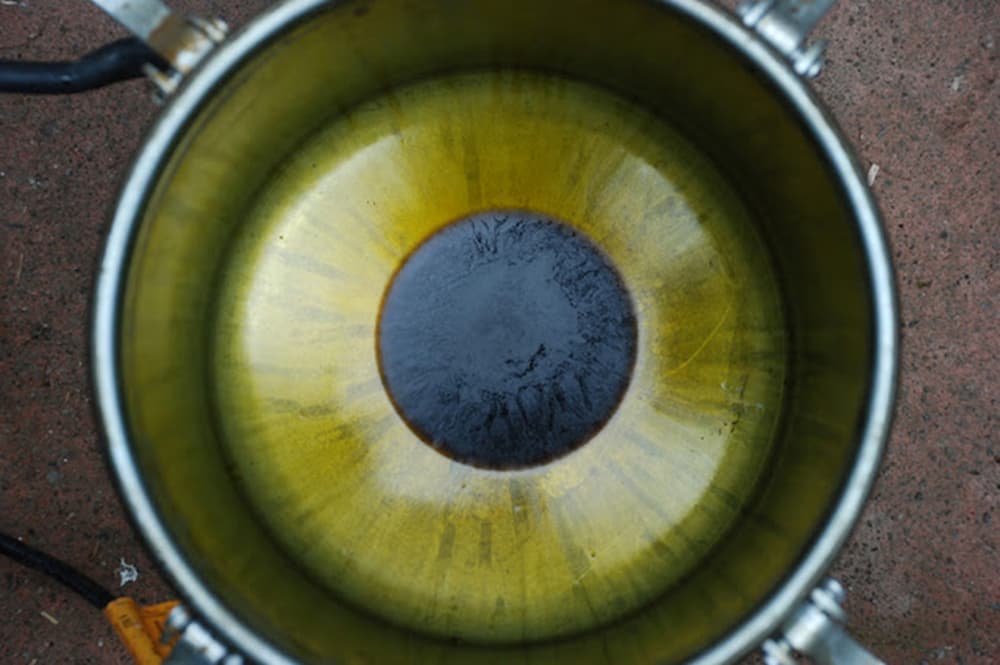

Here is the yield from first run using a 1 1/2" C 24" column:

I posted the results on both Skunk Pharm Research site and at 02-07-2011 on IC Mag at:

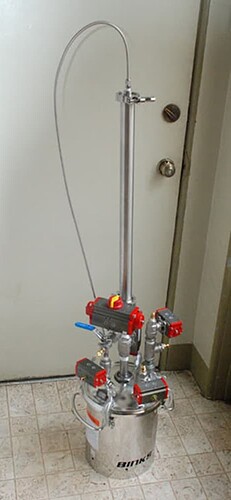

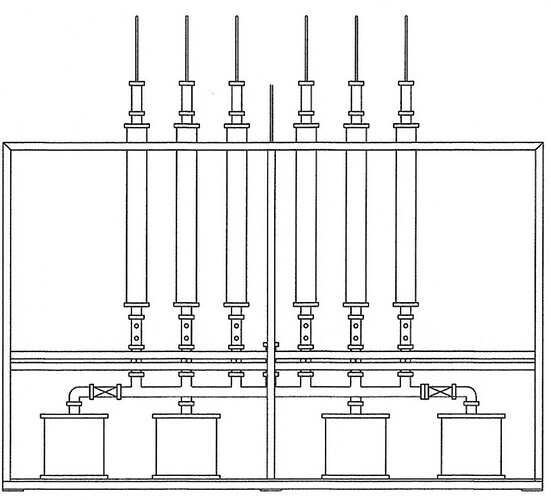

6.9.3.2 The Mk II was the next Terpenator off the line and like the Mk I was based on a paint pressure pot, using a 2.5 gallon Bink’s stainless pot, but instead of building columns from stainless pipe, we used 1 1/2" X 36" stainless sanitary columns, and this one was fully automated after loaded and told number and length of cycles.

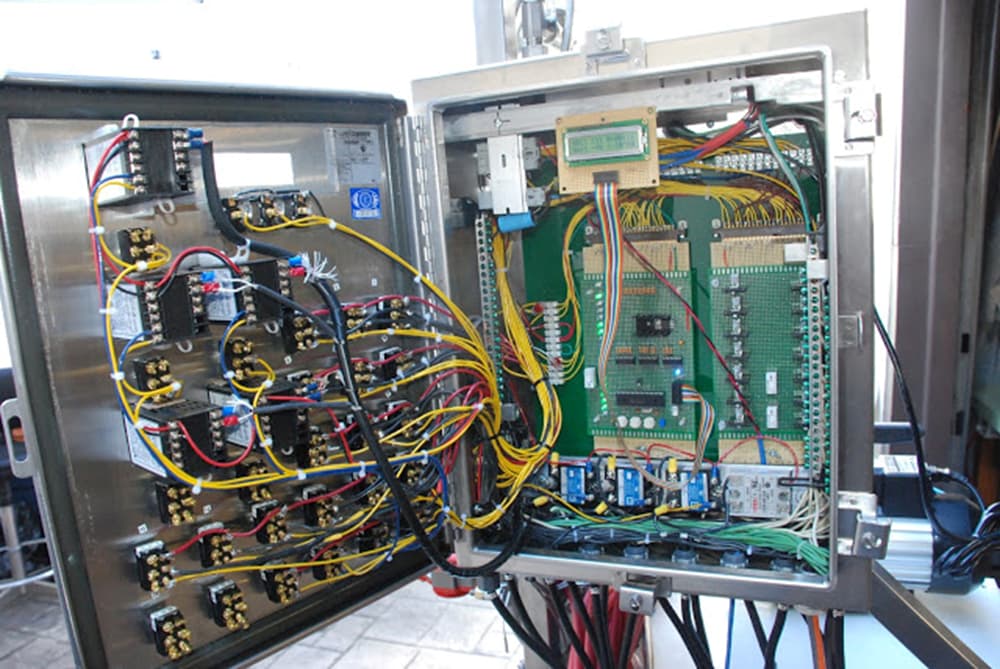

The controls were built by Pacific Semiconductor Inc (PSI in Portland) and used a PC and adjustable pressure switches for set points.

The valves were all pneumatically operated and we installed the Mk II in a ventilated exhaust cabinet that pumped 3,500 cfm air in the top, and forced it out the bottom vents, giving it a face velocity of 194 surface feet and .4 air changes per second, or a full change every 2.5 seconds.

The controls and pneumatic solenoids were mounted exterior to the booth.

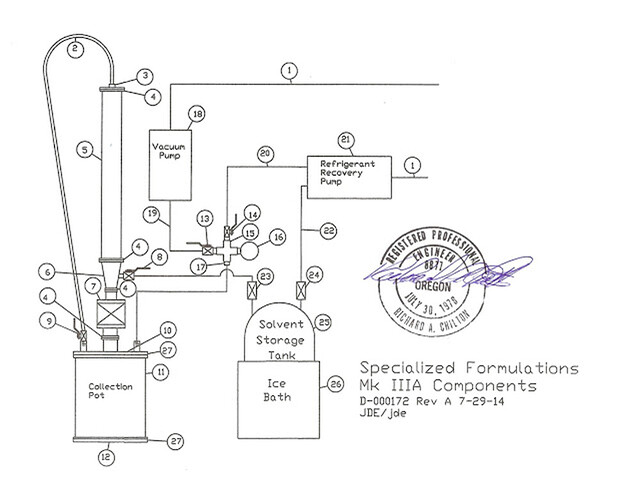

6.9.3.3 Enter the Mk III and the cannabis extraction industry has never been the same. From those spools, I built the first Mk III Terpenator and Lil Terp. I posted those details on line as well at both Skunk Pharm Research and IC Mag forum at:

Mk III at: Mk III Terpenator | International Cannagraphic Magazine Forums

Lil Terp at: Passive Butane Extractor and Reclaimer | International Cannagraphic Magazine Forums

I say the industry has never been the same because not only did others start to build the Terpenator internationally, but the Chinese jumped right in and started offering the parts already machined and welded direct. I supported Terpenator startups in at least four other countries besides the US of A.

Add to that that once my brain fart (epiphany) was revealed to the fertile minds in the cannabis culture, any number of lights went on and variations sprung up by different manufactures, centered around sanitary components originally intended for the brewery industry.

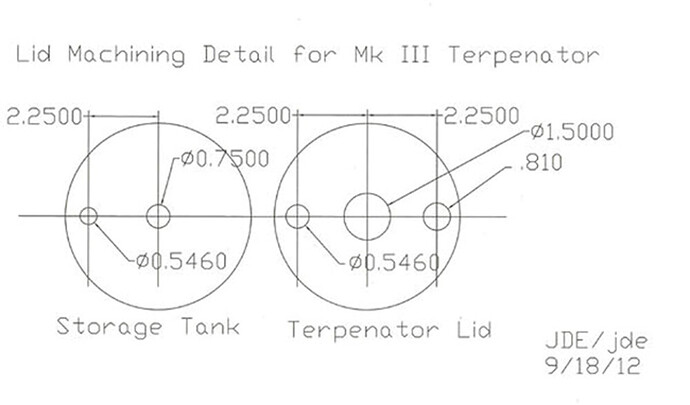

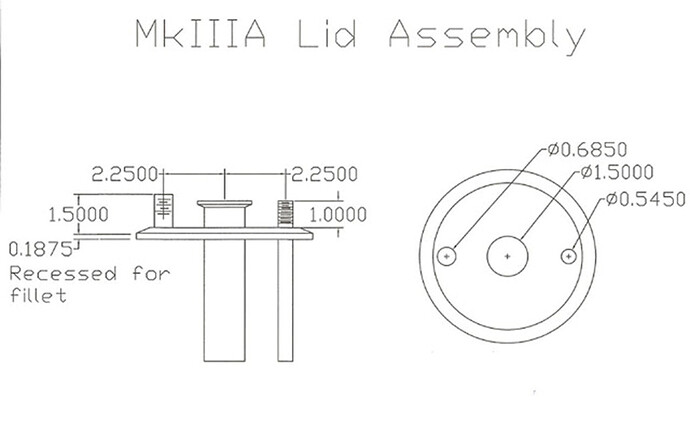

Here is the Mk III lid machining detail, starting with a 6" sanitary tri-clamp end cap.

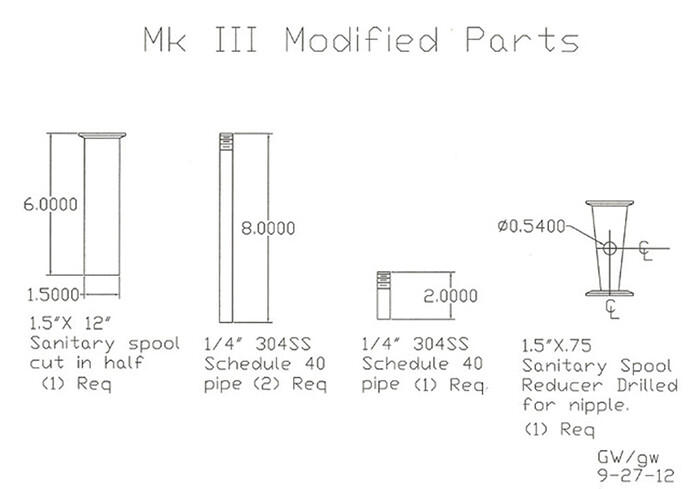

Here are the balance of the modified parts:

Here is the lid assemblies:

Parts from Glacier Tank, machined by Moody Machine Works, and welded by Gibson Welding. Received and loosely assembled in my kitchen:

Here is the shakedown run on the Mk III prototype.

And the yield from the pilot run was good considering, we used poor grade trim.

Part of our research at Skunk Pharm Research, was supplying cannabis essential oil pro bono to end of life and other seriously ill patients, and as a result we sometimes received large trim donations, and met on weekends to wade through it collectively as a group.

Below is such a gathering with both the Mk I and the Mk III prototypes dueling to see which had the greatest thru put. You can see that by the time this was taken, the original Mk I prototype had become the Mk IA, because we had replaced the original Schedule 10 columns with ANSI four bolt flanges, with sanitary triclamp columns, similar to what we used on the Mk II, and it has heating cable wrapped around the column.

The Mk III doesn’t have column heating, but still produced more per hour under the same conditions, using a 24" column.

More history at:

6.9.3.4 The Mk IV Chimera, Mk IV Phoenix, and Mk IVC

Because of the limited evaporation area afforded by a vertical 6" sanitary spool, I conceived the Mk IV Chimera, which used two 6" X 12" sanitary spools turned on their sides for the collection tank. While I mocked one up, I didn’t follow through for a couple reasons.

The first is that it is a tongue in cheek compromise because although the tanks offer copious surface area when half full, their surface area reduces as the level drops, due to the curved walls of the tube lying on its side.

The second is that when the Mk III demand overcame Glacier Tanks reluctance to order 10" and 12" X 12" sanitary spools, I scrapped the Chimera design and went with the Mk IV Phoenix design instead, based on a 10" pot, and added the Mk V based on a 12" pot.

More history at:

Mk IV @ Mk IV A Phoenix Terpenator | International Cannagraphic Magazine Forums

Mk V @ Mk V Terpenator | International Cannagraphic Magazine Forums

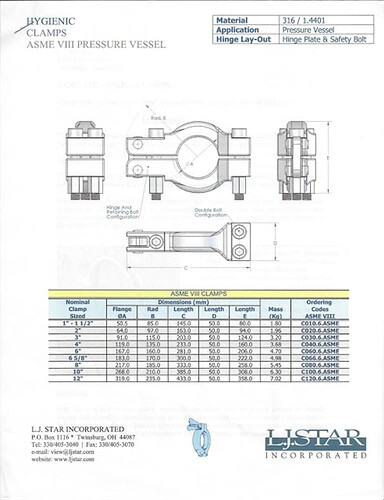

My next step was to have the Mk III, IV and V designs peer reviewed and certified to meet ASME Section VIII, using an independent ME PE, and then the fun began.

I also applied for and received the registered trademark for Terpenator:

6.9.3.5 The Mk V, Mk VA, Mk VA2, VB, & Mk VC

A friend asked me to build him fully automated Mk V beta unit, to which I agreed to do for the experience, if he would pay for the actual development and build costs. A pact was born and I did and he did, resulting in the Mk VA.

I had the stainless cart built at Trilett in Oregon City, and assembled the unit in their shop, but before it was complete, I was importuned by another friend to build him a manual Mk V beta unit quick like a bunny for the fun of it.

I again agreed for the experience, and Trilett was able to respond with another cart quickly enough that the manual unit did ship within the requested schedule, and before the fully automated one, because of less complexity.

She was affectionately named Johnny 5 by her proud new owner, and here is a peeecture of her second run, that demonstrates his enthusiasm and says a lot about why he felt that way. Operating his manual machine also helped in developing a program for the Mk VA close behind.

The Mk VA was not given birth so easily, but with PSI Bob’s stalwart electronics support, and my friend’s patience, she rolled out of my garage where I had installed the finishing touches.

I was able to shake her out and develop the process, by setting up a popup canopy with privacy panels in my driveway, and we were able to load her in the back of Siskiyou Sam’s pickup afterwards with grunt power, loading the cart and then the ancillary components.

Sam subsequently lovingly named her Beta Bitch, as we refined her and worked through the details of her idiosyncrasies.

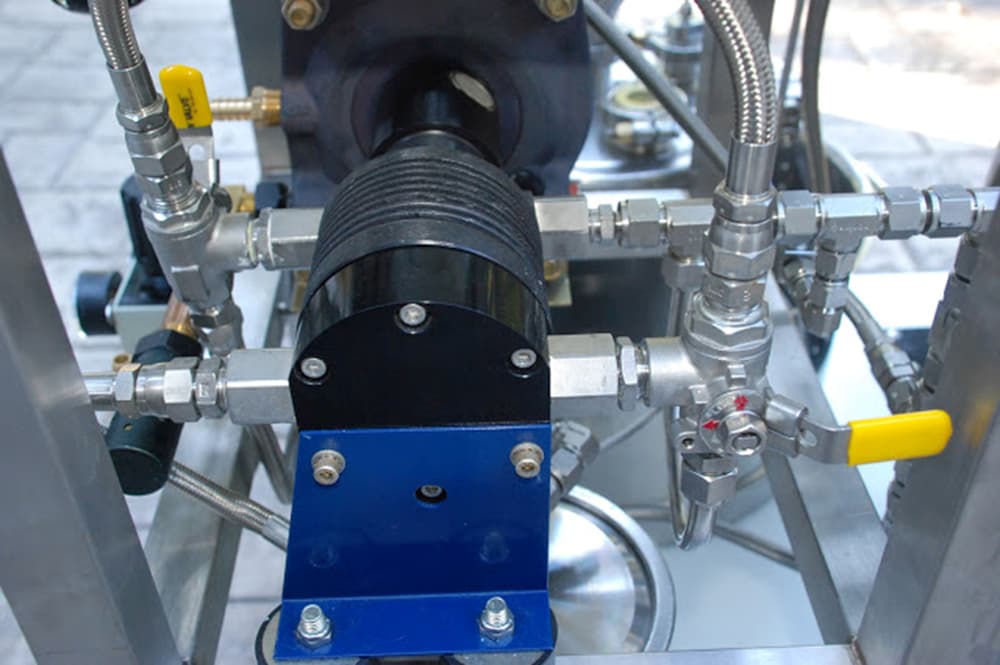

Here is Beta Bitches frame with Mk V kit mounted, using pneumatically controlled valves.

Here is Beta Bitches first production run:

And lastly by Beta Bitch posing with the first Mk IV and V prototypes assembled from parts we imported directly from China.

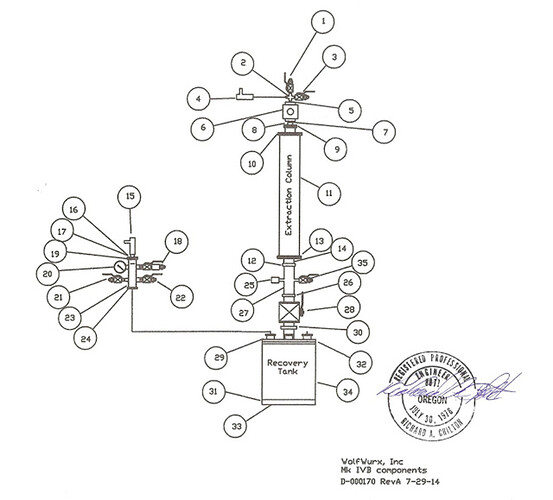

Which brings us to the next chapter, when I helped my son start up WolfWurx, Inc, whose mission was to develop and market the Terpenator product line, and we ordered (10) Mk IV and (10) Mk V parts kits built in China by Wenzhou Kingstone Valve and Pipe Fitting Co, ltd.

The overall quality was good, with some shipping dings and we sold some off as kits and built some complete turnkey systems using the kits as the central core.

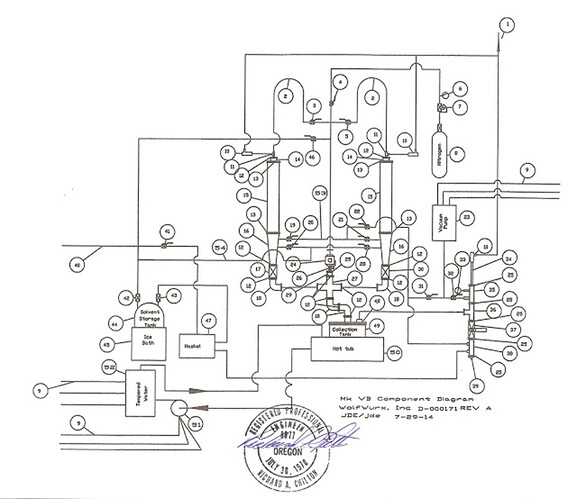

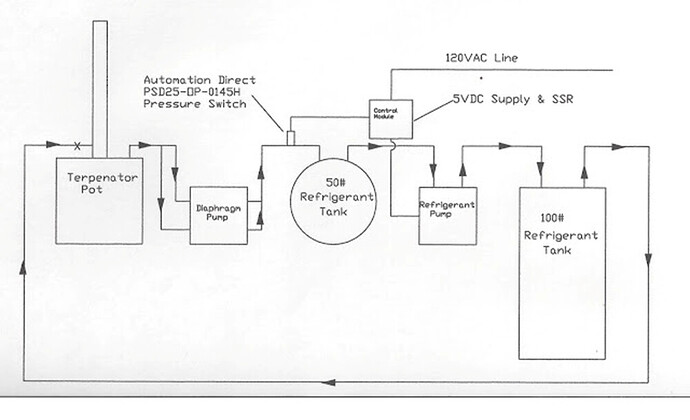

Jenny, Mk VB2 with diaphragm recovery pump. She was plumbed as follows:

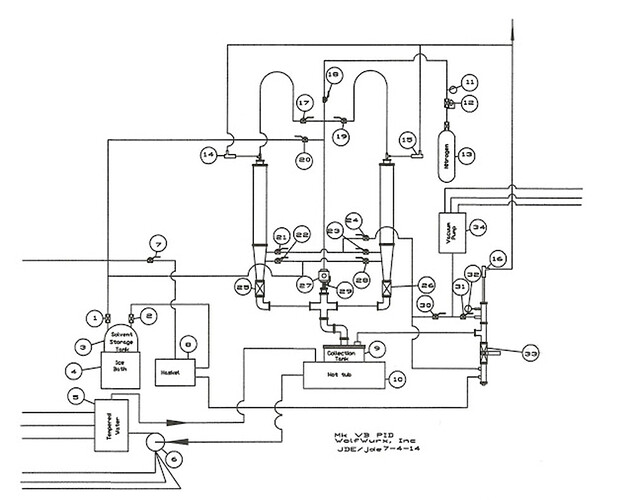

While the rest of the standard Mk VB was plumbed as follows:

And we added a tri-coil heat exchanger for chilling injection and pump exhaust using alcohol and dry ice, or a process chiller.

Beast, Mk VB, pre-distilling Butane.

Double, double toil and trouble;

Fire burn and caldron bubble.

Fillet of a fenny snake,

In the caldron boil and bake;

Eye of newt and toe of frog,

Wool of bat and tongue of dog,

Adder’s fork and blind-worm’s sting,

Lizard’s leg and howlet’s wing,

For a charm of powerful trouble,

Like a hell-broth boil and bubble.

Double, double toil and trouble;

Fire burn and caldron bubble.

Cool it with a baboon’s blood,

Then the charm is firm and good.

Macbeth: IV.i 10-19; 35-38

Mad Shatter, Mk VB

Big Bad Wolf, Mk VB

The last Mk VB was SN-000012 R2Weed2, certified to ASME, IBC, IEC, and NFPA-58 in WA WA land by Kirkland Dynamics.

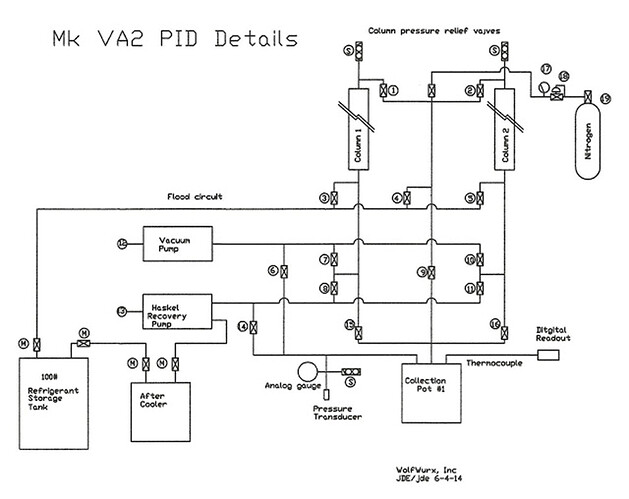

The next automated units were Bertha and Mary, the only Mk VA2’a built.

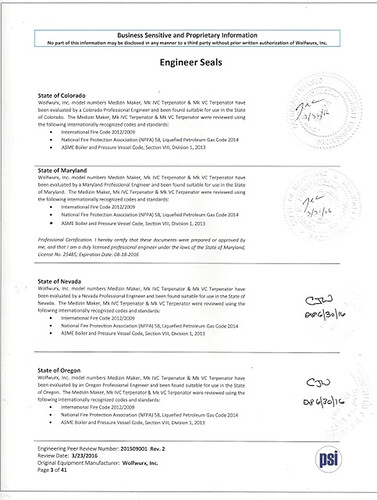

Enter Medizin from Las Vegas, whom I built Medizin Maker for, the very first Mk IVC and the first unit to be certified to meet ASME, IBC, IEC, and NFPA-58 in OR, WA, CO, NV, and MD by Pressure Safety Inspectors, LLC (PSI) in CO. They certified the Mk VC at the same time.

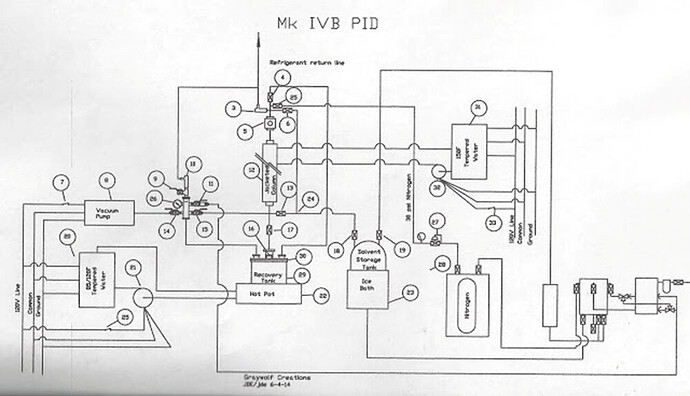

The Mk IVB with Tricore exchanger

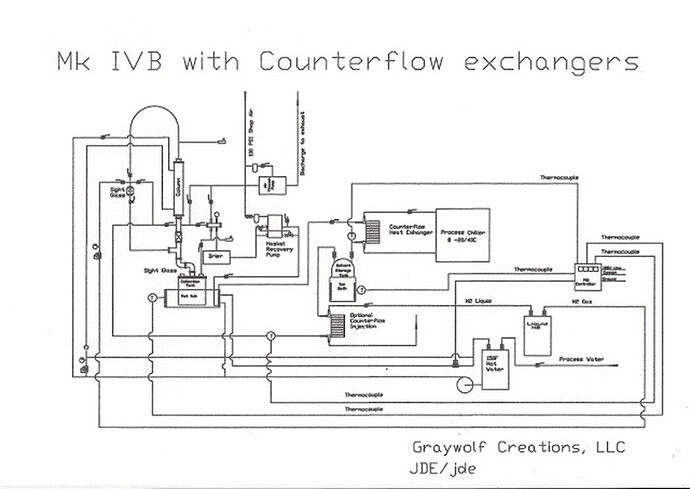

The Mk IVB with counter flow exchangers

TheWolfWurx, Mk IVC was similar to the Mk IVB, except for upgrades to the components used and addition of three more PRV’s.

We upgraded to a custom collection pot by an ASME tank manufacturer, increased the wall thickness on the stainless tubing, including the counterflow heat exchangers, so as to be able to get it certified by PSI to ASME, IBC, IEC, and NFPA in OR, WA, CO, NV, and MD.

The Pharmgold Mk VC was also made to the same specifications, but built by Pharmgold rather than WolfWurx.

I would share the details of that upgrade, but those details now belong to Pharmgold.

Here is however the certification cover sheet for the WolfWurx certifications from PSI and some pictures of it.

Medizin Maker SN00013. The last WolfWurx built unit.

The Mk IVC incorporated the same Haskel EXT-420 recovery pump used on the Mk IVB, both plumbed so that it can be used in either single or double stage. As it is pneumatic, it meets NEMA 7, Class I, Div I requirements.

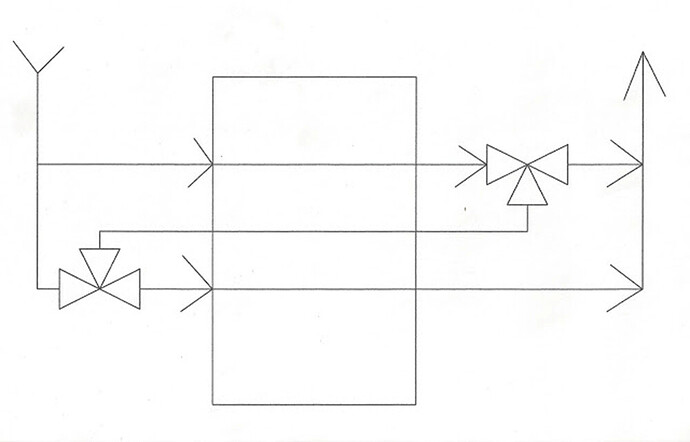

Plumbing the Haskel to run either single or double stage.

It also uses N2 backfill so that when the system is opened, it is below 10% of Lower Explosive Limits (LEL).

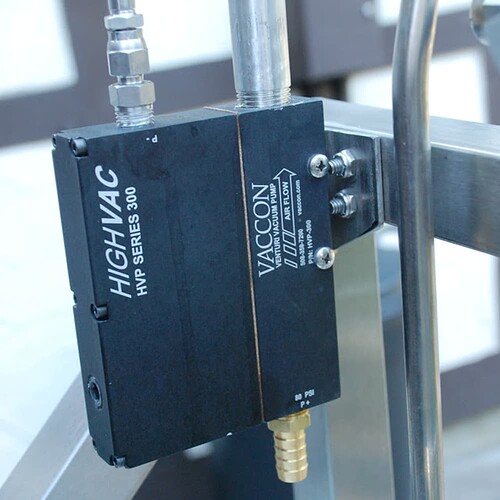

A big departure on the vacuum pump however, as the Mk IVB & C switches to a Vaccon Series 300 venturi vacuum, which has no moving parts and is NEMA 7, Class I, Div I. It will evacuate to -29.5" Hg on 80 psi air pressure and 22 scfm.

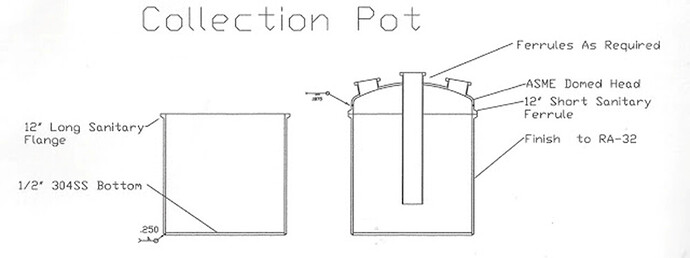

Another new feature is the choice of either a Binks ASME pressure pot, or a ASME pressure pot custom made and certified by Marks Brothers. There were subsequent prints made for Pharmgold, but here is my conceptual print, the actual final prints ended up property of Pharmgold.

Below is a Binks pressure pot being used in this application.

Another big change from the Mk IVB and IBC, was adding a cyclonic filter drier on the inlet of the pump, and removing the mol sieve filter drier after the pump. Several customers subsequently reported back at how effective the design had been in protecting their pump against inadvertent flooding with liquid LPG containing essential oil.

The vessel shown holds two #48 filter zeolite filter drier inserts, which can be recycled by baking under vacuum, or is easily replaced without all the dust issues associated with Mol Sieve.

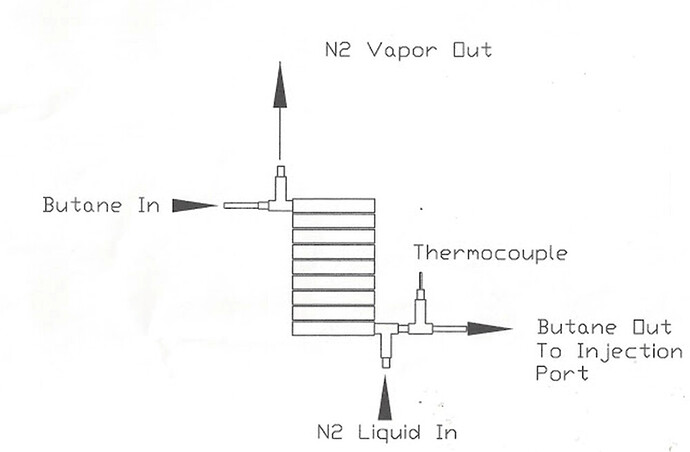

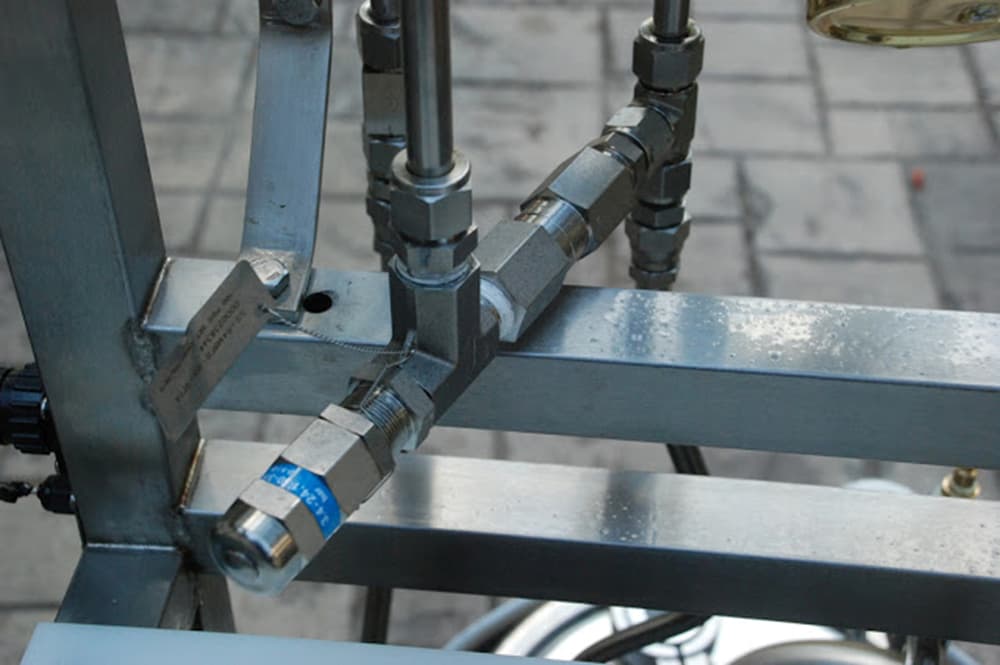

Another big change was moving from the tri-core heat exchanger to counter flow heat exchangers. To certify the Mk IVC, I had upgrade from the Mk IVB counter-flow exchangers, and get the required .049 minimum wall thickness on the 1/2" stainless tubing. I had to have them custom wound by Albina Tube in Tualatin, and used modified Swagelok compression tees to finish them off.

One counter-flow exchanger uses liquid N2 as the refrigerant on the jacket side, and drops the injection temperature to between -30C and -50C. There is a thermocouple in the discharge that tracks that temperature.

The other one cools the pump discharge, using a Temco Fisher Merlin 150 -15C process cooler. The coolant discharge from the counter-flow exchanger is subsequently routed through the heat exchanger coil in the storage tank bath, to keep the tank temperature around 0C/32F.

Mk IVB Counterflow Heat Exchangers

Storage tank cooling coil, that uses the discharge from the counter-flow heat exchangers above.

And of course we had to add multiple pressure relief valves, some of them with a check valve in front, to handle vacuum. Swaglok custom designed this assembly for us, which we used on all the Mk II’, IV’s and V’s.

Lastly, everything that isn’t NEMA 7, Class I, Div I has been relocated to an adjacent room.

Both pot heat and column heat are provided using hot water, heated and maintained by our in inhouse designed in line heaters. The pot heat has a 2kW heating element and the column heat has a 6kW element. They are both controlled by Type J thermocouples and PID controllers.

They are skid mounted for installation ease, and share the equipment room with the Merlin 150 process chiller and the Polar Air screw compressor.

The pot heater just recirculated the water in the pot bath, so the volume never changes, but the column heaters have to go from circulating mode to flooding an empty column without cavitating the pump, so has to have extra hot water volume available to it. I accomplished that by adding a surge tank in front of the pump, which could be refilled between uses.

Here’s the original prototype inline heater. It uses a 1/3 hp hot water circulation pump right out of the Grainger catalog, a 1/4" Type J tubular thermocouple, and a 2kW heating element from Grainger, though when we built the Pharmgold unit, we redesigned the lid to use a Tempco element. Sorry I can’t share that print or information.

Here is a link to a Medizin video demonstrating Medizin Maker strutting her stuff:

Moving right along, WolfWurx, Inc was traded to Pharmgold and Medizin Maker, Mk IVC SN00013, was the last unit built by WolfWurx. Some of the upgrades required for certification were actually finished at Pharmgold after the trade, and the unit was shipped with a WolfWurx name tag and serial number, but with Pharmgold labeling.

Note that this picture doesn’t show the new Marks Brothers ASME pressure pot, or the new counter flow heat exchangers.

Notice all the Swagelok valve handles are color coded to aid the operator in rapidly recognizing them, and this turned out to be a good feature.

Medizin Maker leaving the WolfWurx lair and heading to Pharmgold

Below is Graywolf at Pharmgold, with the first and last unit manufactured by Pharmgold, a Mk VC, SN PG000014. It was the last unit shipped before Pharmgold closed their doors.

6.9.3.6 The Mk VI

Besides the Mk I through Mk V, there were designs for Mk VI through Mk VIII that were never built. I actually did the Mk VI conceptual for a customer, whom changed jobs in the middle and the project fell by the wayside when he left.

6.9.3.6 Mk VII

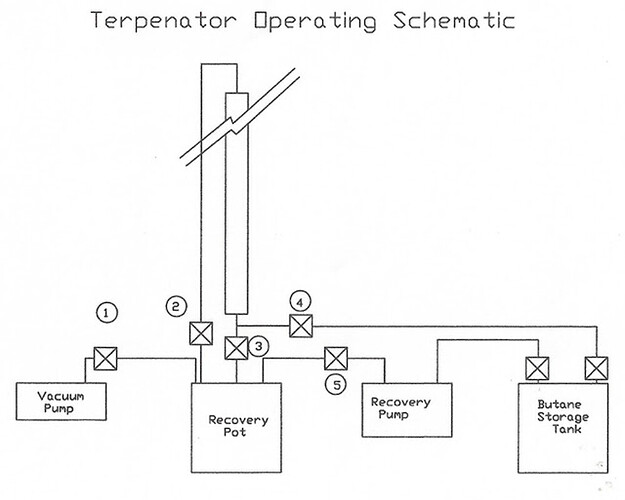

Here is the schematic for the Mk VII, which is a system incorporating inline dewaxing. The Mk VIII used cold boiling to achieve the desired temperatures, but I replaced the design with the Mk VIII after I determined that a high percent of Propane was required in the mix, for it to operate at the temperatures desired. Here is more history:

6.9.3 The Mk VIII

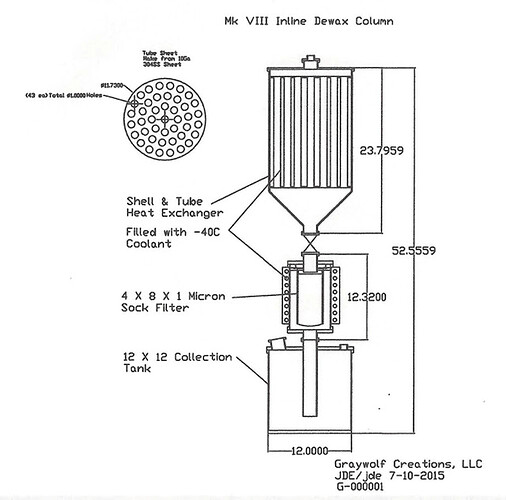

Below is the Mk VIII inline dewaxing column, which uses a shell and tube heat exchanger to chill the solution, and then vacuums it through a 4" X 8" polyester felt 1 micron sock filter to remove the plant waxes that precipitate out.

The refrigerant side of the shell and tube uses a -40C process chiller. The filter section is also kept at -40C, using a stainless coil and insulated jacket.