Dosen’t help that I recently broke my wrist either!

Ok now were talking about torque and bronze vs brass, but what about the length of the bolt corresponding to triclamp size?

i enjoy seeing you so out of breath vs this triclamp

you mean I’m not supposed to make them squeal and squeeze the gasket out?

yeah, I workout… you can tell… do you even torque wrench bro?

squeal starts around 100 inch lbs

I seriously think I bent a bolt in my learning days.

I set it down in the water for recovery and those bubble filling up the air space In the tri clamp would freak me out. I’d start tightening. I definitely bent a bolt or 2 . had to buy new ones from killa glad the tri clamps are so strong bc I was dumbass

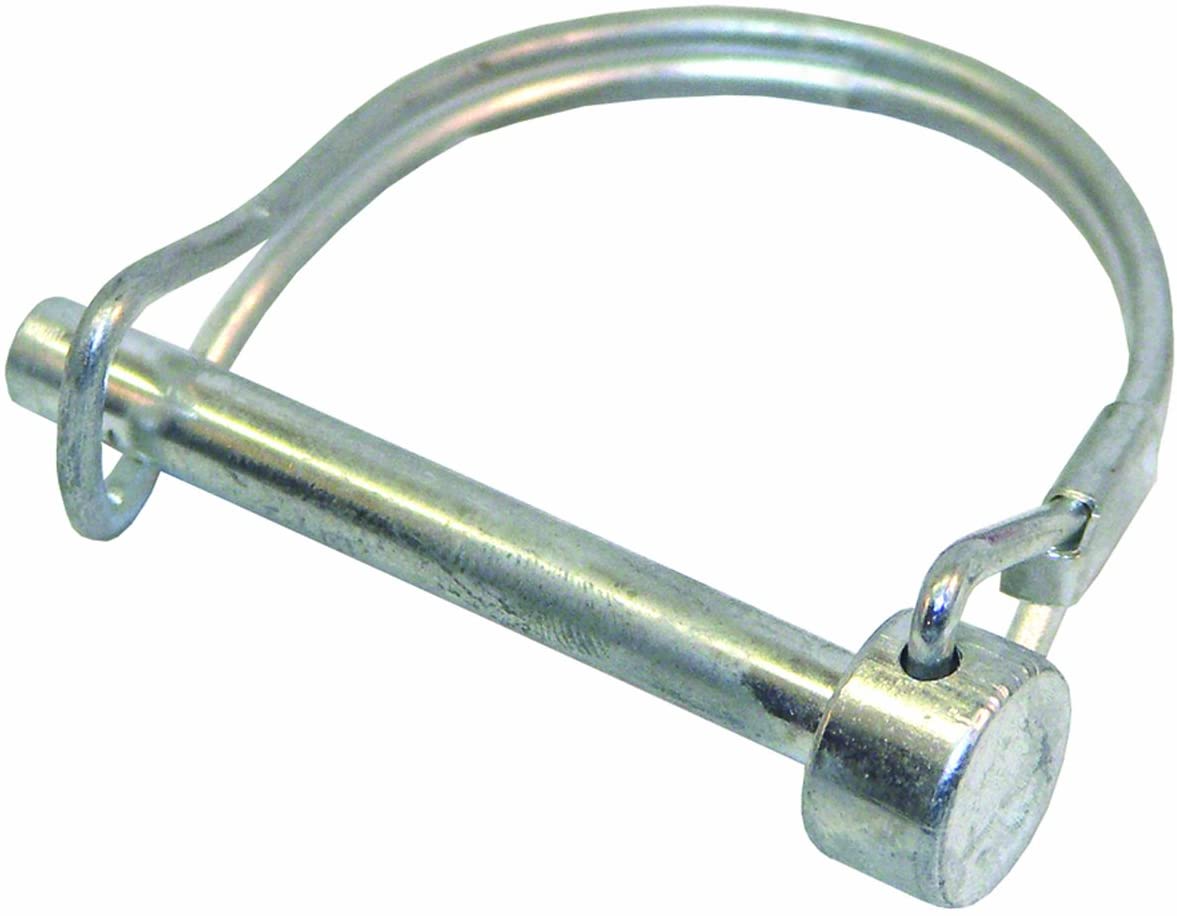

single pin quick clamps ONLY.

I have single pin clamps lower on the setup that I am tightening in the vid, the apparatus is meant to be used under vac, no positive pressure.

Thanks for the vid @Soxhlet

I’ve tightened one of those so much it de-threaded the wing nut ![]() We were able to pull the threads off the bolt without breaking them, looked like a spring

We were able to pull the threads off the bolt without breaking them, looked like a spring

i want part 2. @soxhlet vs Tri clamp… Lets see who gives up first. Tri clamp is wearing @Soxhlet out at the moment…but its a long fight!!!

That video is crazy, thanks for the testing and sharing. @Soxhlet

Fwiw, my experience with squealing sounds has been at much lower values. Mind you I was using a cheap torque value attachment and was a few years ago, but Ive never torqued anything over 70inch lbs and even at lower numbers of 40 - 50 which was my range for under 12" viton, I’d get a decent squeel or squeak happening, at the 70inch lb for 4" ptfe gasket I’d be squeeling like a mofo, I ditched the ptfe cause I hated how hard I’d have to torque to get a seal. All brass nuts from Glacier Tanks or China direct.

Might as well brainstorm and try to see if we can improve. @Waxplug1’s already thrown out some good idea’s.

@crash, I bought mine from the USA from Austenitix, the yare shorter than the brass ones I believe but have the same thread count and such. Im going to double up with a brass after the bronze. I know they’re available from Bolt Supply type shops aswell, but was ordering some gaskets and thought they are specifically selling them for clamp nut replacement.

What about something like this for each bolt, except not quite as much of a ‘U’ and a bit beefier. Almost like a safety.

Anything over 6 inch triclamp should be thrown in trash

@Waxplug1 I ALWAYS doubled up on those brass nuts when running CLS and it kept me from ever having a leak or galled nut.

Blessings to this man’s family and loved ones… it’s always hard to see young people leave this world

In b4 the part 2

I use 12" for collection pots, whats your ideal alternative?

I also want to point out that one of the main issues with this accident was not just the nut failing, but the fact that his column was unsecured and launched after the bottom connection failed, and sounds like that was the fatal oversight.

Are the common rack column clamps good enough at commonly seen pressures? Perhaps securing them with a chain similar to other pressurized tanks would be apt.

It’s called mondo strength ![]()

![]()

But what if you have a 12” lid