Hey all, I have received so much advice and opinions from multiple people on this forum

(HUGE SHOUTOUT to @Soxhlet who has given me a ton of advice and tips) , and would like to see what other people have to say.

I am having trouble with yields and would like to see what everyone thinks could be done differently or improved upon to increase maximum yields and efficiency.

We used to run NO CRC and cooled our columns with LCo2 and would run -60 to -90 F

We opened a new spot and the owner purchased a CLS from Extractor Shwaggo.

This machine is a basic CLS with an MVP for recovery Machine is set up in this order…

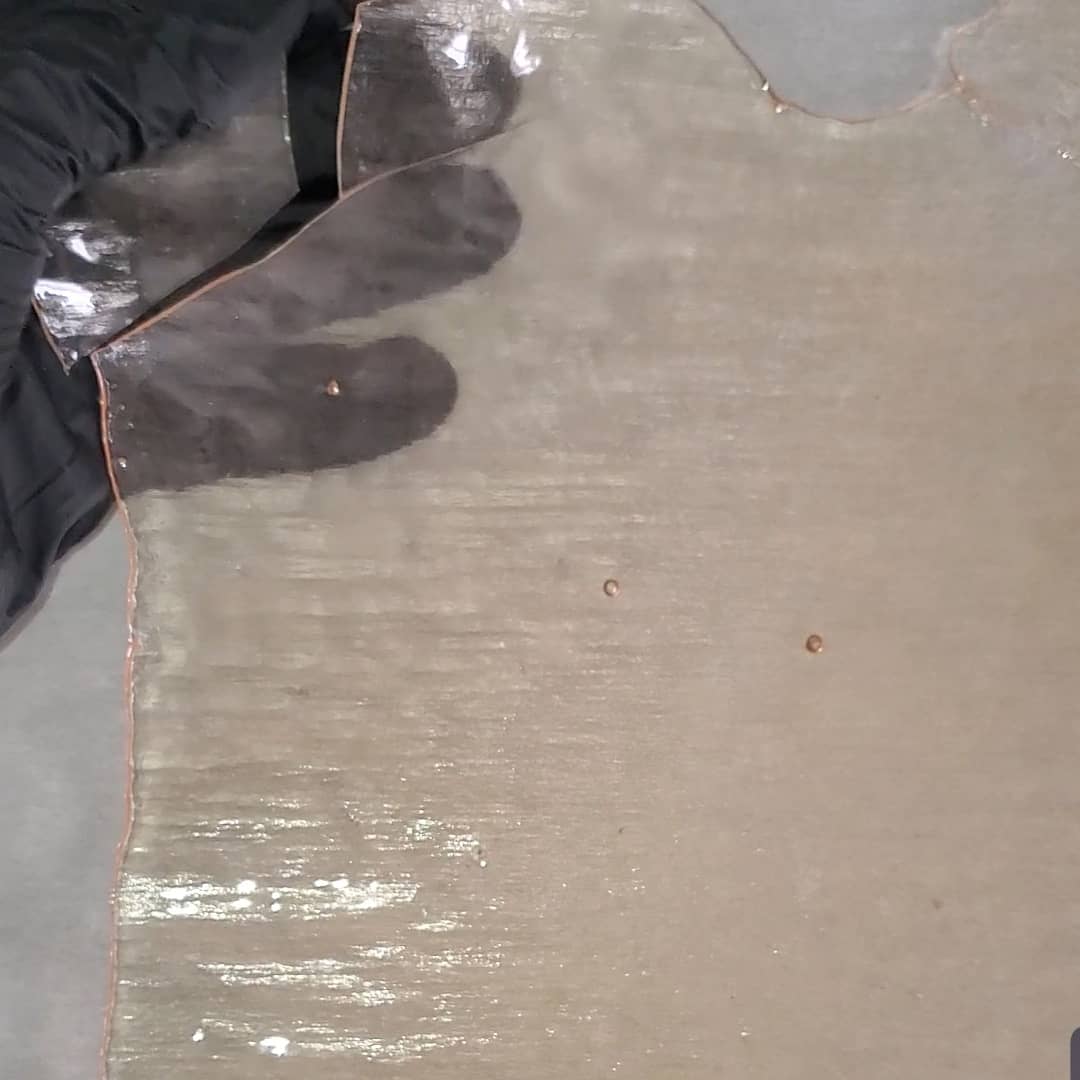

—> Non-jacketed 200 lb Solvent tank —> two 6" x 48" material spools ( they have closed jackets but we dont chill them atm)----> Directly below Material column is inline crc spool (6" x 10" ) filled with our powders and absorbents… —> reducer----->Collection Vessel —> MVP for recovery---->heat exchanger with just Dry ice -----> back into solvent tank…

THE PROBLEM: yields are bouncing all over the place. but more importantly I am noticing lower yields on everything we run. Some runs are great but most are very mediocre.

The process:

This method was recommended to us and worked great for the first month until all the yields started dropping like crazy.

First, let me say we run warm butane ( 0 to 5 Celsius )

we inject into material column A, which holds 7 LBs of biomass.

This normally takes about 15- 20 mins to inject,

at 10 to 15 psi we kick the MVP on which drags pressure in honeypot to 5 psi during rest of injection.

once full

we Fill Column B which also Takes 15-20Mins to fill

Meanwhile Column A Soaks.

Once column B is full.

We immediately dump and flush column A.

Once flushed and drained

We flush column B

Each column Receives a 50 lbs of gas per 7 lbs of Biomass

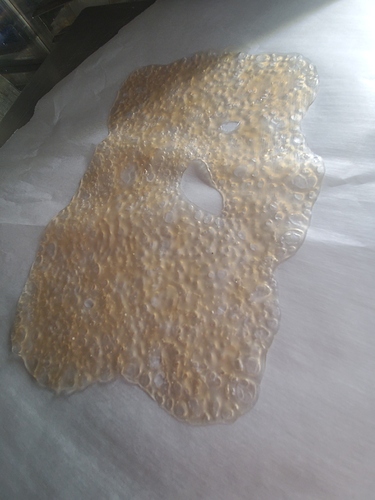

CRC powders for example are usually in accordance with estimated yeild. for example sake we will say the CRC has 200g T5 then 50G T41 with 350 grams silica 60 per column.

During each column getting drained and flushed we typically throttle the ball valve barely open to ensure no channeling in powders.

we do not bake or prewash out powders and have gotten yields above 22% without doing this.

desiccant dryer gets change often fresh gas always cooked over periodically. No visible moisture on honeypot or solvent tank.

We seem to be yielding less than we should. Stuff that always pulled 13% seems to now be pulling 8-9% this is why too much of a loss.

Please give any information that may be of use…

Maybe im soaking too long with warm gas leading to evaporation and crappy yield,

Maybe im filling to fast/slow causing some type of channeling.

Maybe gas is just too warm… but i thought people run warm when making crude which has huge yields lol

Maybe not having cooled jackets

idk

I am not an expert but also IMHO not a complete rookie.

for this one im all ears… Assuming im not using too many absorbents and getting yield loss from that.

what could be causing this. what do you guys recommend and what could you see improved?

Thanks again and sorry if I missed some steps or terminology.