Hey folks! Who knows what about steam extractions? Is it viable for extracting cannabinoids and terpenes? What are the ups and downs? I was approached with a lucrative deal but I don’t know enough. Looking to start a conversation.

I’ve never heard of it for cannabinoids, just terpenes.

What literature are you basing your question on? Or just what someone told you they thought was possible?

Do you have wisdom to share on this subject?

Many folks have tried myriad ways to employ steam extraction to cannabis. I have used steam distillation to further refine extracts but never to extract from plant material. However I am full of … ideas … lol.

Here is the problem really. In order for steam to carry away any given volatile component it stands to reason that physical contact between the steam molecule and the volatile compound must take place. Steam has limited ability to penetrate things like cell walls and such. So when I am doing steam distillaton on extract it works because intimate molecule to molecule contact is happening owing to the fact the plant matter has already been removed.

Not so with fresh ground plant material. The desired compounds may be partially exposed but much is still entrained inside plant material that the steam cannot easily penetrate in order just to get to the good stuff. There may be a way involving superheated steam to create condtions so the “oil” is exposed but this is technology that has tricky requirements because superheated steam is explosive. I believe the reason we do not see mention of successful steam extractions is because the oil we are after is not generally exposed to the steam so all we end up with is a fraction of available medicine. Perhaps with an orchestrated R&D effort and a good budget a technique to overcome this will develop but I have seen no mention of anyone doing it. Terpenes are more volatile than cannabinoids of course so stand a better chance of being picked up and moved by steam but even then the same principle applies and anything that cannot escape the plant material so as to make contact with the moving steam molecules gets stuck inside plant matter. Remember that for this to get pulled off you need to find a way to keep the steam moving past exposed compound at high velocity. Water vapor just lingering won’t do it. You sort of have to create a big and ongoing “wind” so to speak in order to pick up the “dust” which in this case is cannabinoid.

Where there is a will there is a way but with steam extraction of this particular herb you are faced with pioneering the tech sort of from scratch. Somebody will figure it out at large scale someday I bet but for now it has not happened. In all cases I have considered for this it seems inescapable that temperatures must start to fall into the superheated steam realm before there is a real hope of making the concept viable on any sort of scale. “Superheated steam” is a very dangerous thing to deal with safely. I shudder to think of the expense of R&D to bring the concept to safe commercial success but who knows? Perhaps you will be the one to figure it out and I wish you luck but these are my two cents. ![]()

Same. I have heard of cannabis essential oils being derived this way for the terpenes, but you are at the liberty of the steam being a constant temperature.

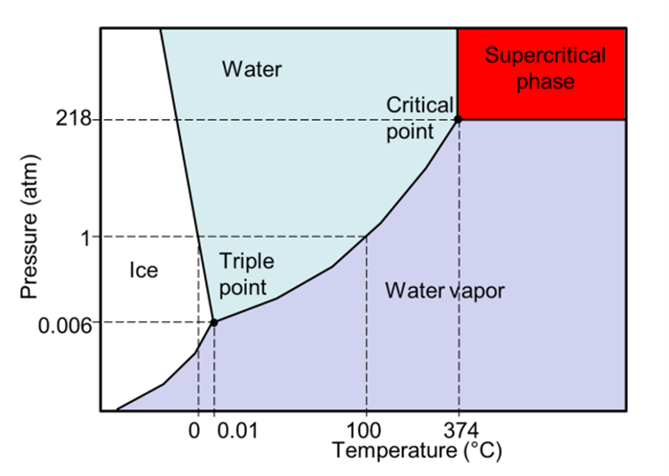

I’m not basing this off literature. I was at the MN hemp forum and was approached by some interesting people who are working on some prototypes with steam under pressure that elevates the temperature of the steam.

No wisdom. The idea sound great. From what I know of essential oils, steam is used for extraction. Since steam is a constant temp it only extracts the terpenes that have a boiling point at the same temp. So, In theory, if you can heat up the steam under pressure to a temperature that matches various cannabinoids boiling points, could you extract the cannabinoids with this method?

Much appreciated. Really puts things into perspective.

I’m TRYING SOME STEAM EXTRACT NOW NOW I PUT SOME BUD IN MY EXPRESSO MAKER AND IT WORKS LIKE THE PRINCIPLE OF BUBBLE HASH BUT WITH HEAT NEXT, I WILL TRY THE WAX IN THE AM FOR MY WAKE UP IN AN EDIBLE SINCE THE STEAM, IN THEORY, MAY HAVE DONE SOME DECARBING I MAY GIVE IT A ZAP IN THE MICRO TO BE SURE, I WILL ALSO SMOKE THE BUD 2.5 GRAMS TO 7 OR SO

Saturated steam extraction of terpenes and terpenoids has been used since the 1700’s but only up through about C-15, as the C-20 di-terpenes/terpenoids and above, have too high a melt point to work well.

I once considered trying pressurized dry steam to increase the temperature, but never followed through.

PS: I saw a video of a setup by which saturated steam was run through a cochlea spiral of stainless tubing, that was buried in a pan of aluminum shavings, sitting on a propane burner, and which produced steam hot enough to blacken white paper.

Steam isn’t a super viable option for cannabinoids from my understanding. Hot air is a viable option, but difficult to implement on the condensation side of things.

You could get the system to around 300psi and see if that would work, but it would take very high pressures to cover the temperature spread you’re looking at with steam alone. Even at 250psi the temp of steam only ends up being 200C which may be enough to start co distilling cannabinoids if you were under a vacuum. But… under pressure that’s a totally different story… I’d imagine you’d have to get much higher in pressure to accomplish a co distillation with water. Looks like the BP of THC at atmosphere would be 425C theoretically. So basically you’re looking at very high pressures in order to accomplish this process. Also degradation of THC into other isomers is a concern when using such an aggressive process in the presence of oxygen.

with that being said I’d recommend sticking to solvent based extractions personally.

It worked but was weird it isn’t soluble with alcohol now and is not fully extracted after testing both the bud leftover and the wax, about 40 percent of the buzz is left in the weed but both worked ok just for fun I had to try it out and it isn’t any better than other methods so why have weak ass concentrate unless solvents become outlawed

Hello everybody,

I signed up for this post because I recognized a crafty community! ![]()

Superheated steam at reduced pressure is the solution to this problem.

In late summer of 2019 I had this obsessing idea of codistilling cannabinoids with water.

I found the patent about this method from GW quick and I can’t wait for it to expire this summer.

The Idea since refluxed in my mind and in a friends basement in spring 2020 because it was operated at ambient pressure and the water just condensed in the plant material when it was still cold. :C

Solutions to the condensation issue is 1. preheating under reduced pressure 2. microwave preheating ![]()

I theoretically figured out that it should be possible to use steam at about 0,2 bar and 120°C for extracation starting at even lower pressure so the dewpoint of water would be lower than ambient temps.

For approximation I just used a boiling point nomograph and entered vape temps (not boiling points) for different cannabinoids.

Under these conditions, the cut would be between CBD and CBN and there is enough of a temperature difference between the dewpoint of water and a temperature at that the extract would be fluid enough to leave a Liebig condenser so there is good heat transfer for cocondensation.

(If not a cooled scraped surface heat exchanger/wiped film evap mabe even a spinning band column could be used to get rid of the fouling by highly viscous extract.)

Also the extraction temperature is low enough to integrate such a chamber into a pressure cooker serving as heating mantle and steam generator which is regulated by thermostat or pressostat. Steam would flow from the pressure cooker to a pipe that leaves the vessel, through an adjustable pressure reducing regulator for wet steam, back to the vessel, through a heat exchanger that brings it up to the boiler temperature, from top through the integrated extraction chamber, down through the bottom and into a condenser which is fed with water hot enough to keep the extract flowing to a temperated vacuum tak-off adapter and receiver (optional through a fractionating spider). Unfortunately heating tape is expensive but clogging must be prevented to keep pressure und velocity right.

Aerosol formation in-line between the pressure vessel and the water vapor front could be detected to estimate the dewpoint of the extract. (Optical smoke detector)

When operated at the right velocity which would be adjusted by the set pressure drop in the line between the pressure reducing regulator and the vacuum controller that maintaines the condensor pressure the extract vapour pressure at extraction temperature should be somewhere near saturation. Velocity changes the contact time, so depending on the dimensions of the packing and concentration of the desired compunds and its deminishing over time velocity must be variated.

The end point could be defined via absorption(rt-ftir) or maybe fluorescence spectroscopy (data?) mass spectroscopy ![]() or maybe its possible to see darkening of the extract.

or maybe its possible to see darkening of the extract.

I cannot tell with certainty but I believe that under these conditions sodium metabisulfite addition like in the GW method would not be necessary to prevent oxidation and I still don’t know what would be the oxidizing agent. Is it air in the condenser the water itself or something that evaporates from the plant?

Further I am not verry sure if there could occure some unwanted reaction with the sulfites.

A smallscale apparatus from glassware operated at reduced pressure (also in the round flask boiler which needs to be power regulated by a cheap phase-fired controller) could be realized with heating tape around a small extraction vessel and a superheater made from a dimroth cooler with a constantan coil shot into the glass tube by tap water, which is then filled up with quartz sand for heat conduction.

For larger applications agitation or microwave heating and a stacked sandwich type extraction chamber allowing a small layer thickness would be necessary for even heat distribution.

The other extremum of shaping for speeding up thermal equilibration would result in a tubular design with unrealistic steam velocities.

A recuperator for energy recycling should be considered.

Please excuse any strange vocabular or spelling as english is not my first language.

I really hope I can inspire you with this to overthink this dead trashed method of steam distillation.

Farid Chemat at the Université d’Avignon et des Pays du Vaucluse also leads interesting developments in the field of green phytoextraction. Check it out.

surpise

jackinthebox

So the actual problem with this method is equilibration without condensation and oxidation.

This problem would occur especially in bulk extractions.

For that purpose microwave heating and agitation under inert atmosphere could be applied.

I did not mention Milestone srl yet. It’s an italian company producing devices for microwave accelarated extractions and other applications.

If these vessels like the ethos xl are able to hold a vacuum and operate at 120°C, they might be usefull for this application.

I am not shure if building such a device would be some kind of patent infringement.

Here is a link to the mentioned patent:

There is also some information about the quality of the extract:

In example 4 they achieved 98% purity of the desired compound with a light yellow color with fractionating of the volatile compounds by stepwise increase of the reducing steam temperature.

Example 5 is about using heated air. Lots of CBN is formed.

Oxidation of THC would be less severe in 120°C steam without reducing agent but decarboxylation would be only partial as it would take about half an hour at 120°C.

In a well tuned process I would expect extraction efficiencies over 85%.

For example dry herb vaporizers extraction efficiency can go above 80% according to this study:

https://www.researchgate.net/publication/291328262_Medicinal_Cannabis_In_Vitro_Validation_of_Vaporizers_for_the_Smoke-Free_Inhalation_of_Cannabis/figures?lo=1

If somebody has ideas for facilitating equilibration, please share.

Just agitate with the inert gases

“Water at temperatures higher than ambient boiling temperature can be applied for extraction. At modest temperatures, ionic and polar species will be extracted. At higher temperatures, in particular approaching the critical temperature, nonpolar substances are readily dissolved and extracted.”

temps are really high though