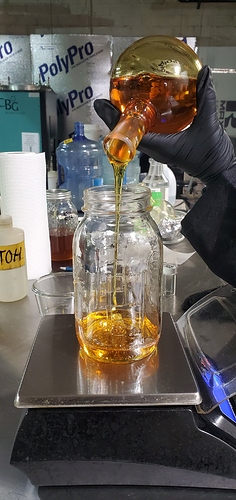

Hello, I have attempted a short path distillation. The main body looked good, clarity and color.

However it has a funny odor. Im wondering what would cause the odor? Is it normal?

At this point I was going to heat distillate in purge oven attempting to reduce odor.

Or distill a second time?

Also how do you all clean the glassware it has the same odor.

It seems a lot of you are well versed in short path.

Thanks from a newbie!

I posted a picture.

Cbd or thc?

What does it smell like? Burnt rubber, sulfur, ect?

I would say burnt rubber, not sulfur, it is hard to put my finger on it.

CBD

Burnt rubber could be from vac levels.

What were your spd parameters?

Mantle temps

Head temps

Vac levels

Type of crude (ethanol, co2, bho)?

Mantle 211

head temp 219

vac 1200

Crude ethanol ext

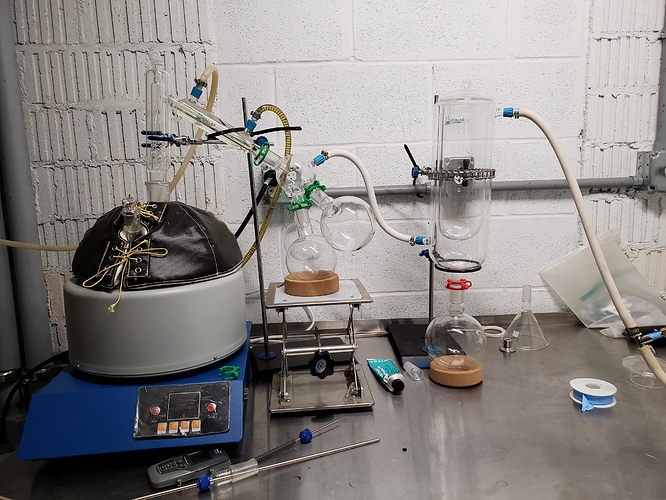

Im using a SOGEVAC SV28B1 I know the vac is a bit high, but I think my digvac needs calibrated.

I have tried everything to create a good vac. Taped threads, use silicon sealant, etc.

I used dry ice in cold trap.

Yes it is normal. Anyone on this forum who has ever distilled anything knows exactly what smell you are talking about. It’s from terps being left in your oil I believe.

Distilling it a second time will help.

Getting your terps/other volatiles out before distilling your mains will help a too. That could also be why your vac levels are high, if you are certain you don’t have any leaks.

Ok, thank you. Would purge oven at high temp help?

I don’t think I have leaks but you know how that goes, Im using the Dow Corning silicone grease. I saw some posts stating you need a better sealant.

The distillate looks super nice, other than odor.

I honestly never tried that, but I don’t think so… It was already under vacuum during the distillation, so I don’t think putting it under vac in the oven will get rid of it.

I think the only thing you can do with it now would be to re-distill it.

Next time, look up how to de-terp your material in the search bar… It can be done in a short path or a rotovap, before distilling your cannabinoids

Your 1200 micron vac level is mostly the culprit.

We/most shoot for under 200 micron runs.

Ok, so that means that the vapors are contaminating the distillate because the vac is not deep enough to pull vaps?

I guess I shouldn’t say “contaminate” but causing odor.

Give it a second pass, work slowly and carefully through the heads fraction on the second pass. Pay attention between 165 and 190 mantle temps and let the heads come over fully. Let the beginning of the main body clean out the condenser before switching flasks. Your distillate looks great, but you’ve gotta do a lot of prep to make clean first pass disty on a short path. I always run two passes.

We clean our glass with acetone >> ethanol >> soap and water for the stink.

Good luck and nice work!

Demontrich is spot on. You will get a much cleaner product with a deeper vacuum. You will have an easier time pulling deeper with a second pass run. I don’t know how your rig is set up, but the cheapo glass/plastic thermoprobes are prone to leaking under vacuum.

Never use tap water to clean glass

Thanks so much for all your input!! I will work on vac and try a second pass.

I rock the same usalab equipment.

Check those vac lines for leaks. As well as the thermowells. Shorten up the cold trap to vac pump lines.

Keck clamp (metal) on bf to head

I would like to shorten vac lines but I have it sitting on the floor. I was concerned with vac pump on bench and vibrations.

a second pass is neccesary most often to eliminate odor

yet @future has a trick with a sonication bath up in the trick of the trade tread

Just wondering, where do you have your vacuum gauge sampling from?

Is that it in-between the cold trap and your pump on the floor?