I need extraction techs second opinion to justify my position, to myself. Even though it seems obvious. I also hope I can post the photos in the comments because it didn’t let me upload them to this post.

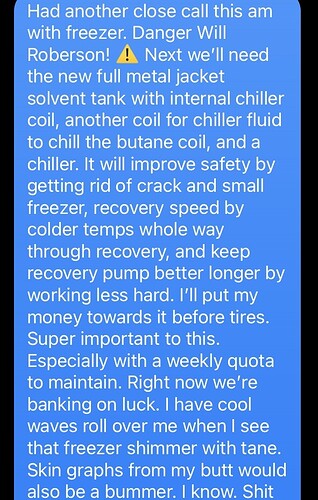

The main topic is recovery of butane. The current set up is a 50lb single walled solvent tank in a half garbage can filled with ethanol in a small deep freezer. Current recovery time is around 11 hours. The lid with dip tube has a spider crack in it. There have been a few too many times where I open the deep freezer to see butane just shimmering in there. To me it’s fucking danger close! We just made a deal with a 500g a week quota and through put has been too slow for any of that. I’m currently using a 6”x48” open jacket spool on top of a 6x24” open jacket spool, with a bottom weld filter plate under that. Then I have three more filter disks 25um 11um 2un paper filters then a 1.5” sintered 1um disk before ball valve.

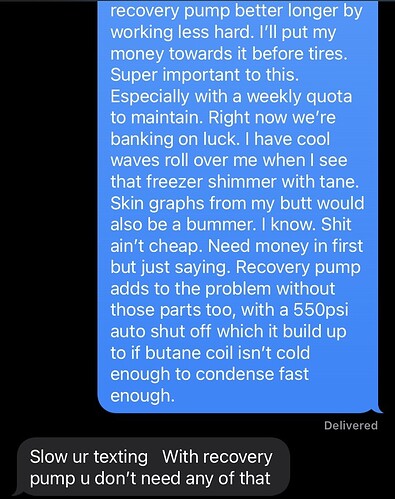

To speed up the process we’re adding a trs21 recovery pump. With a large bvv coil which I’m thinking as it stands, using a second deep freezer with a tub of water with antifreeze (want the ethanol out of situation) for the coil. But in reading the manual for the pump I see it has a 550psi over pressure shut off. Now if the solvent tank wasn’t in a deep freeze and instead was in the breeze with a full metal jacket and internal coolant coil hooked up to a chiller id feel much better about it with the vessel rating of 1500psi. But with that crack and leak I feel we’re banking on pure luck. So then I voice this to my partner and well I’ll try to post pics and see what you say. But basically I want the recovery tank replaced with a full metal jacket solvent tank with internal coil, a second coil for the coolant to go through in a bucket of antifreeze water with the butane coil after recovery pump, in same bucket. Am I on the right track l, and what do you do in the face of…??? Hoping people have had experience where the tech looks at the details and safety and the other guy is just thinking of cost. I’ll try to post the pics. You really need a visual to my dilemma.

The order of the two text photos is backwards**

Walk away until you have a jacketed (or at least a NEW) tank.

That is NOT a game you should be playing

You’re right that the crack and subsequent butane leak are extremely dangerous and you should replace that before using that vessel immediately. there’s no level of production that justifies putting your life and those around you (coworkers, neigbors) in danger. hash labs exploding add to the tarnished reputation of our industry too. i’d love to comment more on your current setup vs what you want to switch to but i think photos and/or concept drawings would help!

EDIT: pics were posted as i wrote this ![]()

Is it actually just the 4” tri-clamp lid?!?

The freezer is a bad idea, but running that tank in there is just plain reckless. Especially if a $50 part would solve the problem…

I’m like butane pump adds to the problem. He’s like don’t need any of that with recovery pump. SMH!!!

I’ve looked for a replacement and haven’t had any luck I’d love to have it and I’d order it immediately

The freezer is slow and contains the gas but I’m remote dry ice isn’t an option. Salt ice is but it’s a mess and then y have to go get it store it pack it etc. So the freezer I dunno is interim but I totally want full metal jacket with internal coil

@Soxhlet & @Indofab can fix you up.

Cap size? Diptube length? Fittings?

If you don’t know those, I don’t buy that you’ve tried.

https://www.glaciertanks.com/dip-tubes-dt-g150-npt6-021.html Can’t find it on their site with their search, but Google found it…

i think you’re on the right track, and i’m sorry you’re fighting uphill against a penny-pincher. a jacketed vessel with internal chiller is pretty standard, as is a coil in a bath (i’ve used ice water with success, your idea will get even colder) the colder/lower psi you can keep that tank and the solvent being recovered, the easier time your recovery pumps will have pushing recovered solvent back in; the harder they have to work, the worse for their lifespan, you’ll be working with higher/dangerous pressures, inefficiency, etc. etc.

can’t express how dangerous your current situation is. convince your partner to invest a bit of money and you’ll be able to hit your quotas and won’t be working in a life-threatening situation.

Not that he’s a penny pincher just we’ve put so much into it already and have yet to even break even now I wanna go spend another seven grand

So all you have to produce is 500 grams a week? I can do that In Like 4 hours on my shed built 3.5-5lber…

Literally 2 runs.

That’s plus whatever else but I’m currently passive with an 11 hour recovery time

4” cap with a 1/2” bored through swagelok fitting and a length of 1/2” tube is the pro way to do this.

I only have one tank for injection and recovery and the dip tube goes to the bottom?

Jesus Christ.

Right?!

GLASS FILTER FUNNEL BOROSILICATE 50/75/100/125/150mm Dia. Chem Lab | eBay This is similar if not the same

Have you read into passive recovery on this sight In detail?

Imo no matter how rural you are, go buy a fucking tote of dry ice once a week and do runs til it’s gone.

Your final product and recovery times will thank me

And your boss, because you won’t be wasting so much fucking time (and able to actually hit your quota)