Completely unnecessary to chill the collection

Why? I thought it helped with creating a mild vacuum and helps pull the solvent down from the material column.

You using n2 right?

He doesn’t iirc

Ditched all plans to use it because I don’t run often enough. So it could just be my process.

Very difficult to accomplish and a lot of energy. I know you know your shit groovy, however in today’s market we have to cut costs which means not wasting energy . In a perfect world yes, get it cold then hot. If you ask me, and your goal is to milk the last drops of gas from your weed sponge, then I would focus on just hot water and use an injection coil to inject cold.

Ok, yeah idk what your setup looks like. But either way I wouldn’t chill my collection vessel. Keep it warm speed up recovery. If your having flow issues then yes it’s the fact you don’t use N2. A recovery pump can also help “pull solvent down” all while recovering at same time. But if you chill pretty much everything, how is it your moving your solvent around with no pressure? Must take a while to do one run in your system?

zero back pressure from the collection is absolutely helpful, and can be achieved by cooling it before solvent hits it.

I plumbed and ran a PX1 that way once upon a time.

(3-way valve: heat vs chill collection)

Allowed me to push with N2 into the collection, vent, then start heating.

With a bigger solvent tank, one can push then vent without the n2 making it into the material column or collection, but given the tiny tank that came with the PX1, this was a reasonable approach.

Stacking runs was not an option, because the itty bitty chiller that the oem supplied took hrs to get back down to temp.

Sweet, makes sense.

I stopped chilling my column entirely too. ![]() .

.

I figured if the solvent is cold why even bother. I get nearly the same results I did if I used a dewaxing column. Personally I think it’s all about filtration. If you go to sub micron you need nitrogen. If you don’t go sub micron it’s a little easier.

I’m all 100% personal use for medical purposes no profits are generated on my end, so I don’t go the extra mile for sub micron even though I have a 6" sub micron filter plate, I’m probably gonna sell it at some point. …

I use 120um>120um>25um>5um>5um>5um. No crc

I’m still on a fairly basic set up just modded a bit to not break my back.

I’m just tossing out whatever knowledge I’ve learned along the way and I seriously appreciate all the corrections on what I’m saying or giving input on the advice I’m giving

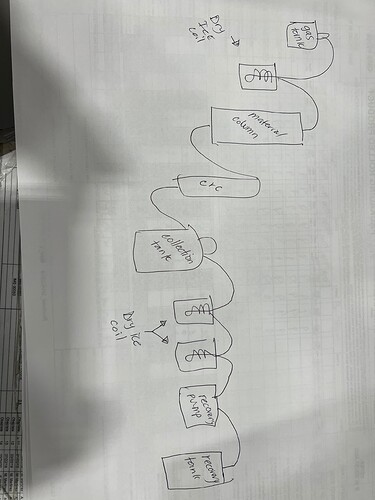

Will this drawing work with the help of a small 3/4 Hp recovery pump on a 5ib extractor ? I don’t have the money for a haskel 2-3k.

I vacuum down my jacket with one shutoff open after I’m done lifting my collection off the dry ice and iso.

The vacuuming down of the jacket after I lift the collection off the dry ice and iso slurry makes it so the frost is cleared and so the hot water can actually flow through the column.

I have a jacketed collection, middle column on top of the collection and material column and I just use them all for hot water.

Not ideal.

Feed pump gas rather than liquid. Condense/remove heat afterwards.

Have bypass so you can use “hot vapor push” on source tank and column.

Don’t bother with two tanks unless you have them already.

do u have any cheap chillers?

No way a -80c freezer is cheaper than a chiller that could drop a column to -30c. @918homegrown Cheapest way to chill your solvent is to use an injection coil(wort) and set it in a stainless steel pot full of dry ice and Isopropyl. At least 50’ in length, then you wont have to worry about chilling your column, unless you’re trying to run live resin. As long as you’re running cold solvent, should be able to get away with a standard chest freezer to chill your columns and material.

I have a couple of them yes view this thread