Im confused. Whats the dry ive and coil for

Just to be a source of freezing cold.

Are you trying to turn it back to liquid?

No, I’m hypothetically trying to use the nitrogen to push the freezing cold from the coil and use that freezing air thru a jacket.

I doubt that will work the way your wanting.

Air isnt a good heat transferer

Me too I was just thinking out loud

this applies to gasses in general, you can make up for it by using a whole bunch of it (air + fan is cheap).

it’s really just about how few molecules there are that can absorb or radiate heat (which is just kinetic energy in the molecules being bumped up or down when they run into another molecule).

solids would work, because they’re nice and dense, except they’re much harder to get good contact with when poured through your heat exchanger ![]()

which is why we settled on heat transfer fluids for most stuff…

you wouldn’t be using the nitrogen to push air, you’d be chilling and “pushing” nitrogen. if you had air in there (which is 70% nitrogen), rather than moving it as a plug, as happens with your (liquid) solvent in your CLS column, the cold air and cold nitrogen would mix as they moved through your HX.

So I was thinking;

This is a stupid thought and probably best to not but I have a clever idea and I feel as though I have to share.

What if you got a column, a base and a recovery tank jacketed with a rated jacket for propane.

You have each jacket have four openings for two coils inside each jacket.

One coil is for cold (propane) the other is for hot (instant hot water heater and jet pump) .

I figure if the propane can’t be recovered why not just send it to a device in the area that would rely on the open blast used of propane; like, say a propane powered instant hot water heater ![]()

![]()

So I figure one coil in the jacket is rated for propane and would have propane regulators w/prv’s.

There would be a manifold on the propane tank to send the propane through the jackets and to also keep the instant hot water heater going after extraction use of the propane.

So you’d send the propane through jacketed collection and the recovery tank and you’d nitro push the chilled solvent to the collection.

While this is happening the instant hot water heater is heating the water to be used for recovery with the exhaust propane from the collection jacket and the solvent tank jacket.

Then after recovery you would close the propane line from the tank and bleed the jackets and the line of propane using the instant hot water heater. Afterwards, you’d use the other valve on the manifold of the propane tank to quickly get propane running to the instant hot water heater again.

Then you start recovery, which would be the obvious you run the propane only through the solvent tank jacket and the hot water from the instant hot water heater would flow through the warm water line.

Would take some doing but I bet it could be done.

We have already done something similar and is currently patent pending / in review.

So far I have been able hit -106c, but going for -150c true cryogenic temps. Just a few degrees away at this point.

I have solved the cascade requirements and high power consumption issue of traditional refrigeration. Our method is a single stage refrigeration system, typically consuming no more than 20 amps. It actually uses less power the colder it gets. ![]()

That’s actually pretty damn amazing to have something that gets more efficient with the more it works! Fucking truly awesome!

It’s pretty crazy to watch… Going from -80c to -100c takes away about 2 amps off the compressor.

I’m going too see one run at some point I promise!

It’s like nothing you have ever seen before. We took a completely new approach to the extraction game with just about everything. Every problem became a solution. ![]()

Fuck yes, that is the one of the reasons why I support your company, and will quickly recommend your wares over BB, or any of the big name equipment manufacturers. There’s literally just about 3 people I would buy from, and I’m sure everyone knows who they are because I try to make an effort to support them!

I definitely appreciate that. It is tough being the one system manufacturer that is completely different from the rest of the industry.

None the less, we should be well over the 1m lbs marker by now. Our local Behemoth is currently processing 2000#/day. ![]()

![]()

Damn two great minds think alike. I was thinking I my head I’m like wait… If it can’t be recaptured then what about being used for other equipment in the area that relies on propane…

I don’t understand your question but I’m guessing it has to do with “how can it cost less energy the colder it gets”

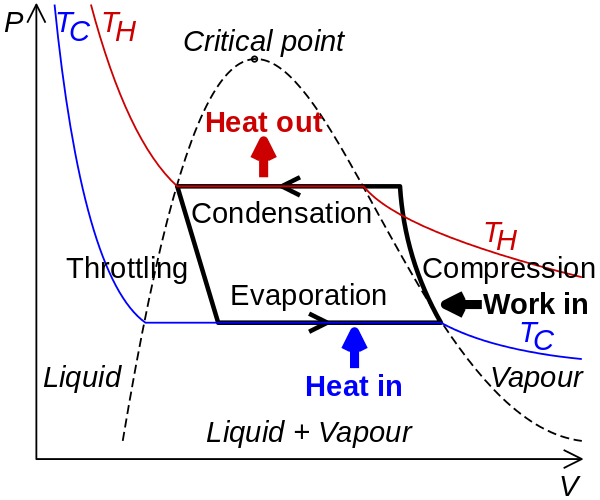

I don’t know for certain but I’m guessing it has to do with a typical refrigeration cycle and in this case, as it gets colder the hot side is less hot, so there is less work required by the compressor to reject the heat of the environment.

I.e. In the diagram below the difference between Th and Tc decreases.

I tried to sound smart and I sounded unintelligible. ![]()

I was amping out a new chiller the other day and I noticed the same. Load drops as it approaches bottom end temps. Makes sense when you think about it.