So, short answer is yes, you would need at least one PRV and probably want gauges. What you’re asking about is pretty much just a chiller, so here’s the basics (I’m sure you’re probably aware how they work but it can’t hurt to go over it, at least for some other mystery reader’s sake):

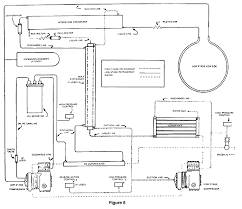

You take gaseous refrigerant and compress it, raising the pressure and temperature substantially. This makes the refrigerant easier to condense, and allows it to condense at a higher temperature than before it was compressed.

You use a heat exchanger to cool the hot, high pressure refrigerant, causing it to condense to a liquid. The basic version of this is just a radiator. It leaves you with room temperature but high pressure liquid refrigerant. This section is called the condenser.

Then you force it through some sort of valve/orifice/small hole that allows the pressure to be maintained in the condenser and causes a large pressure drop. A TXV is the thing to use here unless we’re still in the 1950s. When the pressure drops, the refrigerant will want to boil because the boiling point is a lower temperature than room temp (substantially) at the new lower pressure.

Then you end up with low temperature low pressure liquid refrigerant that is boiling in your evaporator (your base in this example), turning into gas by stealing heat from your system.

The fade out issue I mentioned is this: let’s say you run r404a as your refrigerant (probably a pretty good choice). To run -40 at your base you have an evaporator pressure around 16 psia. To condense that refrigerant at room temp, you’re running a condenser pressure of around 220 psia. This is not an issue if you never turn the system off because the jacket can handle 1.5 psi above atmospheric pressure. However, if you lose power or just don’t want to run the thing forever, it will turn off and the pressure of all that refrigerant will equalize in the system. This will likely leave a standstill pressure of close to your condenser pressure (180 psi is a decent guess depending on the low-side and high-side volumes). That is obviously a problem if the base jacket is only rated for 60psi. Mind you, venting that refrigerant is a big no no

The “basic” solution to this is to make your evaporator volume (between the expansion valve and compressor) much much larger than the condenser volume so that the total mass of refrigerant is such that the standstill doesn’t exceed your working pressure. Basically, if the evaporator was of infinite size, you’d still be able to make some small condenser run at 220 psia because you wouldn’t be stealing that much mass, but when you equalize the system it wouldn’t cause the evaporator pressure to rise at all because it’s just a drop in the bucket.

Edit: @Soxhlet knows how to say it in the right number of words lol