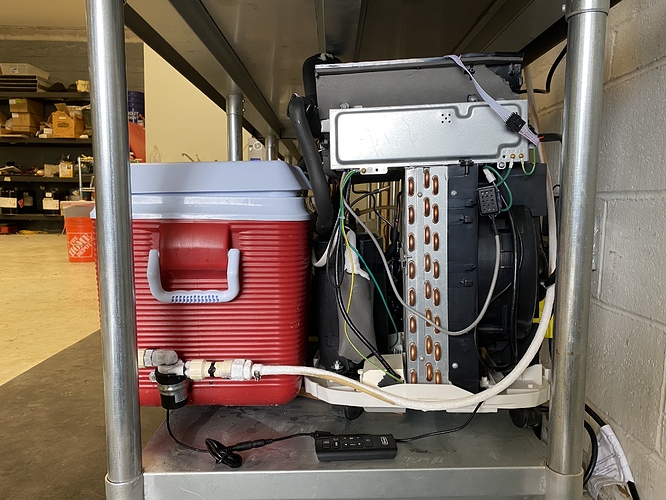

This is who I was referring to…extended the coils so they set in a tub right. Fill tub w alcohol. Turn ac on the lines running through the alcohol chills the alchohol

soooo…using @Soxhlet’s 1k word substitute, and @SidViscous’s well worded suppliement, you should be able to warp your head around using a craigslist CLS and r600 to solve this…

bonus question: does this count as a cascade refrigeration system?

You can make a much cleaner looking one with a window ac. These portable ac’s have a lot of extra bells and whistles you don’t need. It’s even got a remote lol

only if the first stage shares an inter cooler with the second. ![]()

How well does this work for small scale

If you consider the action of cooling the biomass to be your goal I suppose you might be able to call it a cascade system

Lmfao the optimistic side of me made the thread the mechanically inclined side of me read the responses ![]() now both of them gotta work on actually building one

now both of them gotta work on actually building one

it all depends on your AC unit. the unit works exactly as well as a chiller of the same power. it literally is the same thing. a chiller is a AC unit with the evap coil in a reservoir with a pump. this is only a 7000 BTU unit. the coil gets down to -30c, but the reservoir spits out about -10 to -20c. i have it hooked to a lil 5 liter rotovap and it works amazing. it probably loses more heat from the time spent in the non insulated hoses than from the load of the roto.

i imagine if you had a 1-2 ton unit you could easily cool solvent and or a recovery coil. (for CLS)

the pump was $25 on amazon.

At some point one of these days I’ll do a write up/drop a design for a cheap -40 single stage chiller. I dropped a design for a badass 2-stage cascade system but it’s mega overkill for an application like this. I’m thinking something kludgey using a common split system or maybe a walk-in skid because they usually have vapor injection to handle higher compression ratios

Love to see an AC split to -40C chiller hack

So, I’m looking on eBay for what the absolute most common cheap ass 1-2hp split system is but they’re almost all r410 which makes a pretty lousy low temp refrigerant and is awful for DX applications because of the high pressures. Also not very DIY friendly. Anyone have any votes on what system to base this thing off of?

I’m thinking a two stage intercooler-style system running r404a would be ideal but I don’t want to spec compressors that might not be readily available. Also not sure if people would prefer an air cooled or water cooled condenser (I love water cooling but this is supposed to be a redneck chiller).

Seems like a TRS-21, a 5lb recovery tank, and an orifice for the collection base are all that’s really needed to cool with r600.

Oh, And some redneck water cooling on the recovery tank (garden hose). ![]()

Edit: gauges and prv wouldn’t hurt…

Spoon request: where does one find the maths for figuring out things like refrigerant load or orifice sizing?

Yes but we want something more extreme and unnecessary! Or maybe I’m just bored

Extreme and unnecessary? Sounds like a blast.

We need a 2ton refrigeration system that uses a bonfire for cooling ![]()

Edit: what are our refrigerant options?!?

So for TXVs I always just go to Sporlan’s literature. I honestly have never designed a system using a fixed orifice because usually if it’s worth the time to build something it’s worth the $60 for a real TXV. Also, I’ve had very poor results with the tech support at sporlan, the last two times I called and spoke with an application engineer they undersized the valve. But their lit was spot on.

Here’s the bulletin that I pull nearly everything from: 10-9.pdf (1.2 MB)

It’s a bit of a read but it’s very very comprehensive

Thermal expansion valve. I’ve learned something. Quitting time!!! ![]()

So if we want crazy extreme we’d have to use ammonia because it’s awesome and horrible all at the same time. But if we really want bonfire powered, some sort of boron salt like they use in adsorption chillers is probably the trick

what about adding more moving parts?

Steam turbines can be appropriately awe inspiring… ![]()