I just like using the roto cause it also strips some volitales in the process, if you go that route just make sure you stop keeping your etho at around 70c or you will just continue to compound your terps and water back into your solvent.

WOW!

I’m not new to this rodeo, and that sentence took me four readings to decode properly…

so I’m going to deconstruct/paraphrase just incase it’s not just me.

if you are going to decarb in your rotovap, you need to segregate the “solvent” recovered above about 70C from your bulk recovered solvent.

why?

because it will be different!

with more water, and more terpenes than your bulk solvent.

it makes a great cleaning solution, and at above 60% ethanol, also qualifies as “sanitizer”.

If you switch the roto to an oil bath, youll have better success at 120C… most people put the material in a tall beaker with a stir bar and heat under a fume hood until all the bubbling stops, somewhere around 120C eventually

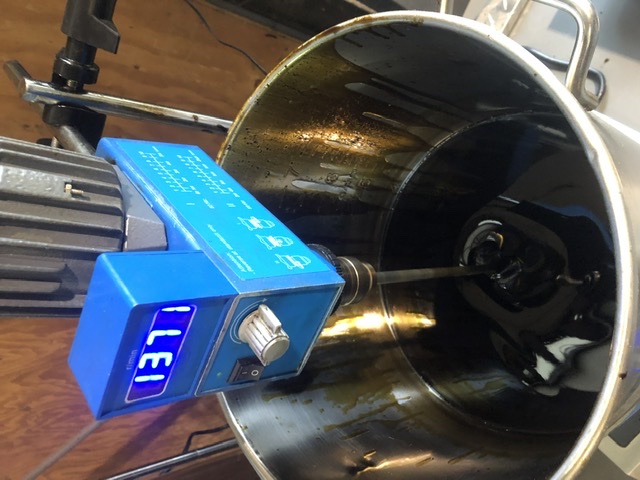

Stainless pot.

Induction burner

Overhead stirrer.

Top one is done

Temp on burner is less important that temp of product.

Aim for 120-140C on product.

edit: is that a cannabis leaf on the burner?!?

Thanks for the share Cyclopath!

One correction to your statement. Decarbing INCREASES viscosity. High viscosity means very thick. Low viscosity means very thin. The more you boil off solvent, the thicker it gets or the higher the viscosity. I ALWAYS get this wrong and at one point in my life I took a screen shot of the definition and put it on the home screen of my phone so I wouldn’t forget it. It’s seemingly counterintuitive.

I would say my best option is to increase temp in the rotovap to 140c at vac and do that for 45 minutes and then put in spd bf. If I can’t hit 140c with the roto I should go As high as I can in roto then hit the forced air dryer at 150c for 30 minutes or so then to the SPD.

I mean in the roto SPD NOT SPD BF.

No. Decarb makes it runnier

You’ve got viscosity right.

we are agreed that removing solvent increases viscosity

and that Heat decreases it

If you have empirical evidence of viscosity increase on decarb, then it is because of the solvent you’re driving off…removal of the carboxyl group as CO2 from THCA to THC absolutely reduces the viscosity.

‘‘Tis why we decarb shatter to make pens…

and why year old barn find will only ever make pull & snap, never shatter.

I feel like how you do it vs how I do it is relative. We both know our lab better than one another. I know that my bottle neck is my short path, not my roto which means I want to use my roto more vs using my spd for the decarb process. For you, maybe it’s your roto that is the bottle neck.

At the end of the day we are both right!

Thanks for the response breakingdabs.

I’ll pry go roto route until my bottle neck hits the roto then I’ll pry go to a hot plate with overhead stirrer.

The inherent issue from roto to hot plate method is loss from transfer from roto to hot plate method to spd. Best bet may be to get another heating mantel to use ONLY for decarbing so that I can transfer from roto BF to spd BF, decarb in round bottom bf on heating mantel then once decarbed go to the actual spd set up without needing to transfer and run it. Only one transfer from roto to spd bf. This is all dependent upon scale and equipment availability.

Very insightful and great point to make. Thanks for sharing. I’ll bank this info and implement this week. Separate 70c+ Condensed vapor from under 70c condensed vapor. Re use under 70 and dispose of over 70c waste.

Or is there a use for the over 70c product?

err…

read much about corona?

I dont keep anything that comes off in the roto past 70c, its usually alot of terps etc. I use the rest that comes off to clean glass etc, i dont want to keep adding more wayer or terps back into my etho storage container and then add it to the next round and so on. Just my process, observations.

100% agree.

before reading what you wrote.

just couldn’t decode it the first three tries.

might just be me…

was my paraphrase incorrect?

Thanks for sharing and it makes sense. I appreciate you explaining.

Ya i use it to clean glass, tables etc, just dont want to compoind a problem in my solvent that will only get worse. If you do it that way at about 130c under full vac you get some nasty stuff that will come off

Ya exactly, its not worthless its just not good to keep adding it yp in all further uses of your solvent in my opinion. If you want you can also add a lil water around 80c and it will help to pull a lil extra volitales terps and such, kinda a quick ghetto water wash

Have you ever used the over 70c to clean and then take a sample of the equipment/table cleaned and inoculated a Petri dish to see if bacteria grows to confirm it actually cleans?

Can you confidently re-use the under 70c ethanol again and again and again to winterize without issues?

Could it cause cross contamination? If so, how do you know? What did you do to validate it?

No its just the first step to cleaning stuff i then follow up with clean etho for glass or whatever as to not waste it or need to use as much for cleaning. Usually ill close the valve once its all the nasty stuff and just toss that usually only a few 20mls or so.

Ive been doing it this way for the last 5yrs and have ran both dirty and clean testing stuff and never had a test fail but its kinda better safe than sorry type of situation. I dont cross use solvents when i know the material is either clean or dirty. Easier to know the cost now than being very expensive at the end