Where they expensive? Wonder how the 3/8 and 1/2 are?

FloLOK SwageLOK and others are good until you reach -50C… then you need cryo valves to finish the job… unfortunately they are hella expensive…

AVCO cryo valves are $550 for 1/2"… but they are rated for -212C and are fail-proof for your extraction needs…

thats really wack, I’ve had the same hamlets on my system for about a year+, no problems, I tighten them every week or so. a couple months ago I got some new hamlets and those are already going out at the stem.

I noticed this week that xd is now carrying compression fittings, lol been waiting on that for a while. might start slowly moving away from hamlets to something else.

do you use those? almost tried those a while back, went with hamlet instead and stayed with NPT… regretting that at this point lol. the hamlets did me solid but I’m sick of pipe thread

where are you using these at on your system?

Only place i found it useful was where my sintered nipple is to bleed out pressure

Yes I use those ones I’ve had abiut 40 of them for a 2 years and only 3 have shit out on me, the 3 that failed, they actually still work I just noticed that they have oil on the valve stem after a few runs so I swapped them out I still kept them for if I ever really need for maybe a vapor line low pressure or just anything that may come up, that’s the worst that’s happened out of all of them. Highly recommend the OSS ones and I get them to -60/-70 every run with my injection and they are perfectly fine.

You still have those swages?

We used mostly Balon in the RJT gas plant I built last spring

I’m doing a project where I want a true 3/4" recovery path from beginning to end.

I had to step up to some 1" Swagelok valves to get the proper orifice size.

The 1" valves are beasts. They weigh 5lbs each and cost about $770 from Swagelok.

The three piece 60 series 1" valve (SS-65TS16) pictured on the far left has a .875" (22.2mm) orifice.

The three-piece 60 series 3/4" valve (SS-63TS12) pictured to the right has a .516" (13.1mm) orifice.

The one-piece 40 series 3/4" valve (SS-45S12) pictured next to the right has a .406" (10.3mm) orifice.

The little 3/8" 40G series on the far right is just thrown in for scale, but it has a measly .187" (4.8mm) orifice.

Those are some bad ass ball valves! I’ve never used anything bigger than the SS-45TS8 half inchers, and those are already tough enough to twist.

Just like Tech demonstrated multiple flow path sizes on 3/4" valves. The same applies to most fitting sizes, There are often smaller body and bigger body valves for a given tube size. That tiny by comparison 43GS6 shares the same body and ball as the 1/4" 43GS4 which is why its orifice is less than a quarter inch. 0.187", 4.7mm.

For those inclined to up their flow rates on smaller 3/8 plumbed systems and with tank fittings that might not make the conversion to half inch worth the cost. It has a slightly bigger brother the 44TS6. It’s still a 3/8" valve so a direct fit to existing hoses, tubing, and fittings but with a bigger body accomodating a larger ball, 0.281" (7.1mm) orifice. 6.0 Cv vs a 1.5 Cv.

45TS8, the one piece 1/2", has the same ; 0.406 in / 10.3 mm orifice; stepping up to a 3 piece 63TS8 offers no increase.

@TwistedStill how do you like those three piece valves on the thing you made to de carb with? Anyone else using them?

I’m shopping for 18 1/2 valves.

Just want to throw this out there… for those wanting to increase the path to recovery, you should consider tube in shell condensers. Make the vapor path 2-3”

Never had issues with the quick connects . Just gotta keep those 3 o-rings maintained.

They are fine for my purpose. I run them in 3/8 all over my rig. I buy them from dudadiesel.

I do keep an eye on all the valves and keep them tight. On occasion I do have to tighten up the fasteners on the 3 piece valves.

So I guess I’m saying the valves are cheap, and if you can live with keeping an eye on them, you’ll be fine.

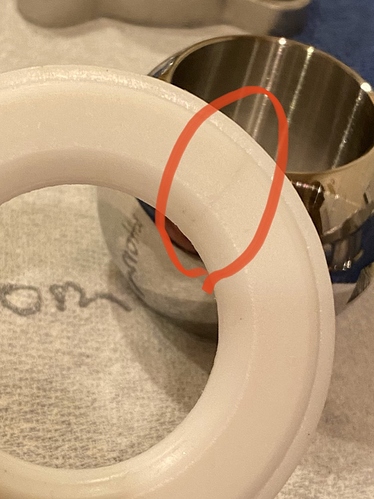

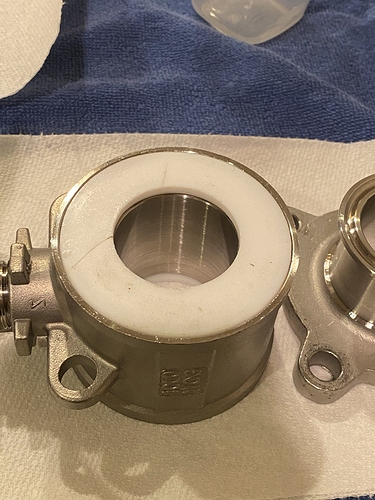

Took this brand new ball valve apart for cleaning and not only was there dog hair and a ridiculous amount of grease, I also found a crack all the way through the seat. Anyone know where I can find replacements in this style? It’s a 1.5inch valve.

Has anybody developed a fix for the hamlet valves without secondary packing nuts? I’m thinking of trying nylok nut and possibly changing seals to ptcfe for better cold resistance.

Seems like you need to replace the seat and keep your dog out of your equipment. Don’t see how dog hair incursion is the fault of the valve.

It was a brand new valve sealed up with a brown dog hair inside of it along with other little hairs and fibers. I don’t even have a dog. I’m also looking for a replacement seat if you can read.

thank me later ![]()