My lab is 5200 feet up so that has to be added into where my vacuum gauge is reading, its almost an inch per 1000 ft. I run agilent dry scrolls.

This time around I’m going 86.5°f with a flip every 24 hours. I’m going 5 days on this one and the goal is 4 flips. Technically it stays in for 6 days.

Ai Accutemp 0.9 Oven and a generic 12CFM 2stage from ebay being used.

100f for first side 8 hours or until no more big bubbles. Flip. 110f for 4 hours until no more big bubbles. Flip. 110f for one hour or until no more bubbles. Immediately cool down using a cold tray from the freezer. Should be fully purged and stable. Low and slow will cause crystallization if properly dewaxed. This is for stable shatter or course.

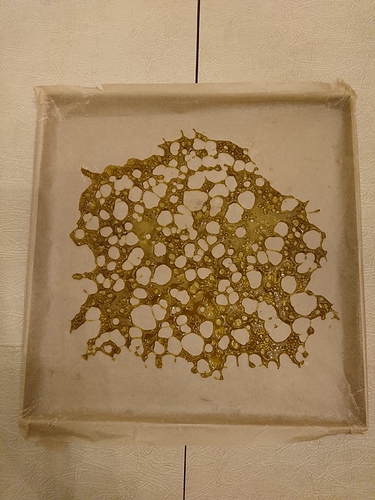

Very Clean, Very Flavorful. First Slab of 2020!!!

This is by far the best shit I’ve ever made and I couldn’t have done it without @StoneD teaching me some new tricks and the stainless solvent tank I ordered from @Killa12345 and of course the support from everyone here @ future 4200.

I purge a lot of slabs around 70°, they get so stable that I think it really does slow down the sugaring process, never thought much about it

Maybe my slabs have too much thca, but 70f will not allow any solvent to release. I’m lucky if I even get a bubble to rise at those temps after the first 4 hours of initial purge.

I also run my varian pump 24hrs. Rotary vane pumps are actually designed to run for days straight. Evacuating a massive AC unit of all moisture prior to charging can take up to 72hrs of constant vac in certain installation climates. I only change my oil when it is contaminated, but don’t be worried about continuous run time on these pumps. They will go forever if the motor is rated for 100% duty cycle.

And as you are pulling vac on solvents and terpenes your pump oil degrades and needs regular changing, or your pump won’t work as well. That’s when they are shut off.

Please don’t compare hvac to this industry. Hvac techs almost always have the worst input. It’s like comparing a guy who works for roto rooter giving input to an industrial engineer. You go ahead and rock out with that Robinair pump from grainger

I usually pull constant vacuum put change pump oil every three days. If you don’t run constant vacuum the pressure is building in the oven and your purging ability also gets worse as time goes on ![]() . Having a bullseye connected to see micron depth is key for this reason.

. Having a bullseye connected to see micron depth is key for this reason.

I also use a dry scroll for this reason. Rotary vanes are used for different types of vacuuming.

Anyone try purging at really deep vac depths? Like less than 500 microns?

Haha I’ve run my AI 21cfm on 2 7.5 ovens for a year without changing oil. I hooked it up to my micron reader for my spd and it was pulling 110-150. Changed the oil a few times and it got down to 2. I fucking hate pump oil. I purge all slabs at 82°

didn’t read every post. but I torture tested an agilent idp-3 hooked up to two vac ovens that were purging live resin and/or shatter with no terp trap and it worked like a champ. I let it run continuously for weeks at a time. the rubber seal on the inside had to be replaced about 2 times over the course of about 6 months. I should mention that when it started to have problems I simply flipped the seal and got about an extra month out of it. I also flip once per day for slabs and depending on stability, if I’m going for stable shatter, I would lightly heat gun the slabs when I did flips.

25-28hg

shut off pump

hold at vac

75-100f

flip once every day

3-6 day purge

Okay so I’m trying soemthing different. I’m doing 87.6°f a flip every 24 hours but every 6 or 18 hours without releasing the vaccum that’s in the oven, pull a vacuum for one min and because vacuum ovens for what we do are giant heated de-gassing chambers I figured if we just pull more of a vacuum on one side over a 6hour or 18hour interval you might end up de-gassing more out of that side of the slab.

This time I plan on going four days. Tomorrow it should be done.

this is how I run my pump

@kay420 I use the same tec without the flip, sounds like I need to start flipping. I was told that keeping the vacuum running is pointless please feel free to elaborate…

Deff flip. It degasses the opposite side. Leave it on one side you’ll trap gas in your slab

@kay420 definitely taking your advice from here on out, I am a novice only been running for 8months.

im really interested to fin out how many people run the vac full time or only run vac to get vac out oven and shut off, I would imagine that only so much vacuum can be pulled so running it full time would just burn out your vac? maybe im wrong?

damn i run my e2m28’s at least 20 hours a day for many days in a row.

took it in for a rebuild and the tec was surprised at how good everything looked. i have also been pretty lax on changing oil constantly.

my experience was if you run to full vac and then shut it off, over the next time period (1 hour or 24) any gasses pulled out of the concentrate will slowly lower your vac. eventually you would not be anywhere near full vac?

we checked our ovens all the time and would hold vac overnight empty but would always loose some vac with slabs in them.

80-90F (depending on strain) full vac 12 hours, fold and flip, full vac 12 hours. would pass residuals generally first try.

lots of cannabis processes are specific to each strain, if they produced more sappy concentrates they would purge quicker, if they were more stable they would purge slower. so always remember your situation might not be the same as everyone else.