Turns OLCC only wants to know so much about your process…

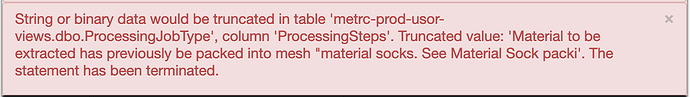

There is an undocumented 1000 character limit on the required “processing steps” description.

At this point I’m tempted to simply give them

It puts the cannabis in the tube, and then it walks away again … See Luna SOP

Either they want to know how we do things, or they don’t…based on how long it took to give us anywhere to describe our processes, I’m leaning towards the latter.