Looks like we might get this same thing in Colorado and Michigan as well. Its been part of my METRC workgroup conversation stuff. How to cover WIP with fewer package tags and stuff.

Their training videos are kind of terrible… like low definition, when you need high definition to read things.

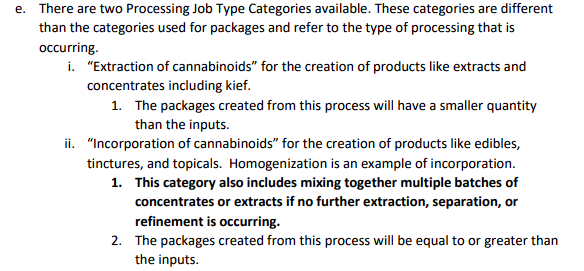

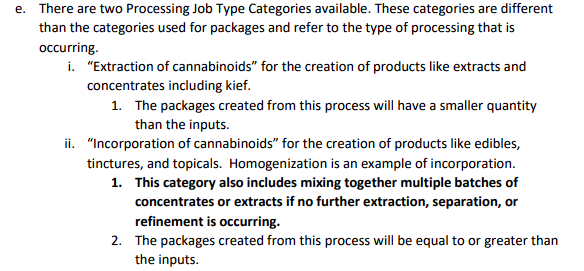

But the training guide has some additional clarity…

I think the key there is “Incorporation” only happens if there will be no further extraction, separation, of refinement processes. AKA you are making a cart, edible, tincture, whatever. -shrug-

Sure its always frustrating when regulators use words to define things that are different than how we use those same words. That’s why its important that we participate in the process (go to the workgroups, respond to the public comment periods, attend the public hearings, etc…)

I mean how many times have we argued about the simplest terms on F4200? Synthetic? Resin? Every category of dabs for all time?

Anyway - I think it cool. Cool as in, I am not sure I would like to use it without actually having to use, but I’m not afraid that it will break the world when it comes to Michigan later this year or next year.

I really like that you can change what happened with the packages, including weights and adding/removing packages from your production batch package using this tool, without having to completely recreate new packages, discontinuing stuff, or calling METRC and begging them to change things. <3

I think its utterly stupid that you have to issue new fucking tags for each WIP step (which we could have done before…) and that this increases the total number of actual tags needed for each process, without adding any additional functionality (besides what I mentioned in the paragraph above) except for perhaps creating a really shitty electronic batch record. I say shitty, cause I will still want to record a FUCKTON of information that isn’t in METRC. So I’ll still have to have a third-party program or a piece of paper to get all of that stuff collected…

But it is NICE that I can potentially maybe… be able to capture and comingle the “cleaning residue” from all my activities that goes into the mother liquor and then get that back out… maybe by leaving a process job open until the very very end when it all gets combined, but I don’t see anything that allows you to combine processing job remnants into one bigger batch without first using additional TAGS, which again defeats the purpose. You could already have created a fucking tag for the 5 grams that is left in your cleaning ethanol…if you wanted and continue rolling that into a new tag for days or weeks… until you finished and came out with a missmash of crude.

I found how you can “reuse” “biomass”…

And that is kind of nice… but again, more TAGS. FFS - how many additional tags now, for no additional information. Its like they some how think that the physical tag really matters (does it, probably not…how many people use the actual tag function, I think no one, so really its just the unique number that is needed…)

And they have still fucked the “waste management” section - by forcing you to say that you created 100 good units, when you only created 96 good units and 4 of them were waste… and then saying you wasted 4 of the good units, which never existed. Which means you still have to keep fully separate books to monitor for process and operational efficiency.

I don’t expect much from METRC… they seem to think only in the context of tags… and that’s what OLCC is using, tags to tags to tags to tags - so that they can “track” our processes more, without actually capturing any of the actually useful information, streamlining costs, or creating more inherent quality.

SAD.