Yep like to see that to

Also I should mention that Hydac makes the same filters in a bunch of lengths, we built ours for the smallest but the length of the housing could be extended infinitely.

Love to see that unit, something like that would be very useful to me.

Show us pictures, damnit!!! @SidViscous

Edit: just want to mention to the fella who bought the delta chilling unit—maybe you should push them to provide a thermocouple or thermometer for the fact that you spent a shit load on their equipment.

Just hooked another one of these up today to our rotovap inlet to pick out all the powders from our heptane polish. Got really lazy and didn’t even bother to wash the media off the frit of the funnel. Had to pack 10 cakes and probably saved a good hour and a few liters of solvent that won’t need to be recovered. Not a trace of media in the oil

Isn’t there a chance of combustion from compressing ethanol? I’m guessing not as you’ve not blown up yet.

Some… it’s really about compression ratio.

You’re not going to achieve auto ignition with a diaphragm pump.

Ignition under pressure of ethanol (akin to what happens inside a diesel engine) takes hundreds of psi, along with a specific air mixture. 15psi of compressed air pushing liquid is not even remotely close to these conditions. No boom boom.

I just posted my post ethanol filtration set up in another thread, but I think this is a better / more relevant thread for it as the other one was dealing with filtering post winterization, so I’ll just copy paste it here.

My setup is kind of ghetto, but it works nice. Was doing 2 dimensional , buchnner style filtration for a while to remove sub 220 micron sediment after cold EtOH extraction. Was using the 5 gal refinement filter from BVV with a 5 micron sintered disc. That thing sucked (but not in the good way that it should). Very slow, clogged easily, etc. Tried that setup every which way - with a celite cake, without, with filter paper, without paper, etc. Either way it was just too slow. And the sintered disc clogged so much that I’d have to bake it in a 450C muffle furnace to make it usable again (never tried ultrasonic bath tho that probably would have worked too).

This works good for our scale. And was way cheaper than a larger set up from Rosedale or similar companies.

I use negative pressure (diaphragm pump) to suck solution to be filtered thru these staged filters (50-10-1 micron) and into a holding vessel. Works nice. Super fast. Takes under 1 minute to filter 5 gallons of cold (viscous) ethanol. I’ll probably keep the 5gal buchner around for filtering over carbon or clays, or whatever, but I am happy to be done with 2D filtration for removing sediment.

And yeah, I know I should probably ground those housings and get tubing that can be grounded. Got to do that and a few other modifications.

My only real problem with this method is the large holding volume in the housing. Have to flush a good bit of clean solvent thru to get everything out.

I don’t know yet what the max capacity is for these things, but I’ve been changing the filters after every 10lb, which for most of you is probably too frequently.

Some things I learned in the process of switching to this method that might help anyone that wants to do something similar. McMaster Carr has solvent compatible cold temperature tubing. However from what I understand, due to static electricity, tubing is probably not the best option. A braided stainless steel hose is probably the correct way to do this. Also, not all 2.5 x 10 filters are the same height. Tried a few different brands and some were a mm or 2 taller than others preventing them from fitting in the housing. It seems the typical Big Blue style houses have a greater tolerance for slightly different size (height) cartridges. I have the same staged filter assembly before the rotovap, but they are PP housings and every filter I’ve tried fits in them. Not the case with the stainless ones.

Sorry I asked a question based on faulty intel and now I’m deleting it to cover my shame lol. Don’t mind me!

Hi

I just wanted to know what material do you use for the filters, polyprop? The problem we are facing at the moment is that polyprop does not do well under -18C, however, some people say that they work fine even at -80C . What your experience been at low temperatures?

Thanks

They work fine at -80C. Have not had any issues at those temperatures.

I actually do not even use the stainless ones in the picture in the post you replied to. They are not good and left too much sediment slip past the filters. I currently use 3 10 x 2.5" big blue PP filters staged 50 - 10 -1 micron to filter after -80C extraction. The problem with them now that we have scaled up a bit is that there’s too much sediment to filter without having to change the largest micron filter. I recently got a large PP bag filter (Pentek PB-420) which I hope will fix that issue. Waiting on some fittings before I can start using it.

Thanks for the feedback

We are going to try a 10-micron bag followed by the cartridge filters. Initially, we will start with a 1-micron PP cartridge and then go lower if required, all at -80C… will give it a go and let you know.

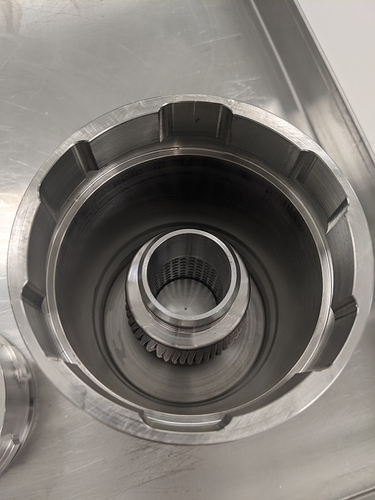

Check out our machine. American Industrial Filtration. Still working out a solid number for flow rate but this is the system everyone is looking for 550 psi average continuous duty.

How big of a batch?.. How big is your holding tank.

Where can we check out your machine. The only website I found doesn’t have any info.

@AIF

https://americanindustrialfiltration.com/

This your website? Needs a hell of a lot more details and info if you want to sell stuff

Agreed. I tried to check yours out but the link didn’t work…

www.speedyoldtruck.com

Hot tip: Apply ice to sooth burns.

Difference is that site is my personal one not my business and I’m not trying to make money with it. If this is your idea of making sales I think your strategy needs some work.