most of the methods i’ve seen are a cost and time sink. we just don’t buy PBO material any more. But prior, i always produced cleaner remediation with 8a molecular sieve.

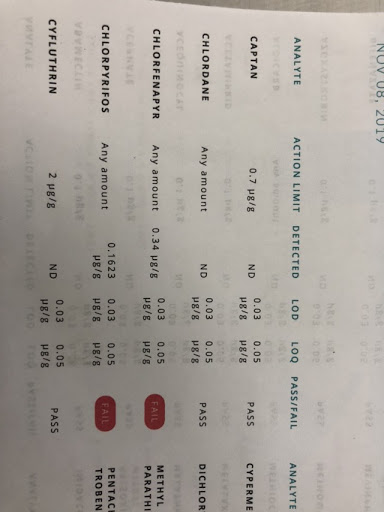

Just got hit by the Chlorfenapyr bug. Did you have any remediation success? I’d love to hear about it!

Any luck remediating chlorpyrifos? Thanks!

Pentane and acetic acid

Will you consult?

any luck on PBO remediation

Greeting Qtp: Oddly, I found PBO in some adulterated MDMA tablets which I was testing for a friend. The tablet, which contained no MDMA, was instead a mixture of a research chemical “MDAI”, and a Tryptamine, and an amphetamine and a bit of PBO. The PBO had been added, I believe, to assure a false positive when tested with Marquise Reagent, the ingredient in the Dance Safe harm reduction color matching field testing product which was popular in the old days. Talk about a nasty additive! I believe the quantity was low, but I was not quantitating, just identifying…

Regarding pesticide remediation, I do have some experience, and something that is definitely different than what I have been reading here, but I must say that in my opinion, the subject has been well and thoroughly covered here, by some very competent contributors of repute. That being said, if any of you are having trouble with Propiconazole, here is how I came to successfully dealing with it, via a procedure that I have not seen here, though I may have missed it… My experience with Propiconazole (and Myclobutanil) came about via a contract I had with a client who had a fairly large quantity of badly contaminated distillate. My initial efforts were sufficient to reduce levels of Myclo down below California limits by mixing contaminated distillate with Hexane, (by volume 1 to 3), in a 5L Chinese reactor with 10% by weight of MagSil-PR, stirring for 20 minutes at STP in my bench reactor (COMPLETE 5L REACTOR [sorry for yelling!] was $240 + $55 shipping from Amazon, of reasonable quality, though high vacuum work requires Silicone RTV due to rushed ground glass joints) and working up as usual, including a redistillation (there was likely some isomerization to delta-8, but my custys did not mention it and have been back regularly for help with this and other issues… Anyway, although the Myclo was reduced enough to pass, the Propiconazole was still over. Upon contemplation I recalled that I had read something from Jansen or somebody who manufactured Triazole fungicides at some point, who had published regarding the stability triazoles for agri use, and had in such mentioned a procedure to cause breakdown of their triazoles via UV with Titanium Dioxide. So, in consideration of about 100mg per Liter water solubility of Propiconazole, washing a suspension of contaminated distillate with Titanium Dioxide and distilled water under UV was what I recalled and was just what the doctor ordered, so to speak. Google helped by providing enough information to verify my recall. Anyway, here is the abstract from Google: [https://www.tandfonline.com/doi/abs/10.1080/03067319.2015.1046054] . It turns out that photochemical reactors are available on The Bay, the auction site, for around $300, and they are useful for this and other pursuits like THC remediation and still more. However, they are not necessary for this procedure. I used my $240 Chinese jacketed reactor ($240 + $56 shipping, complete, still available from Amazon for this price!) [https://www.amazon.com/lab1st-Small-Jacketed-Chemical-Reactor/dp/B07X1MLBFC/ref=sr_1_6?keywords=2L+chemical+reactor&qid=1572561520&sr=8-6] for the procedure, which was simply putting my Deuterium UV Arc lamp (purchased on The Bay, “UV Arc lamp with power supply”, use eye protection) into the reaction portion of the reactor and circulating the mix of 1L of the contaminated Distillate with 6 Liters of distilled water and 25 grams of Food Grade Titanium dioxide warmed to 30C on the stirring hotplate in a 10L flat bottom triple neck flask, stirring as vigorously as possible (to put as much water into contact with as much distillate as possible), pumped as fast as possible with my bronze gear 24v fuel pump would push it, through the jacket of the reactor and back around through the flask for 90 minutes. Once it was operating and there were no leaks and it all looked OK, I left the whole thing to circulate round and round in the lab while I went out for dinner. At the end of 90+ minutes I returned to the lab, drained everything into a 5 gallon glass bottle, added 1 liter of salt solution and sufficient distilled water to fill it 2/3 of the way. I then ran this mix through my “pig filter” (which is actually a 20 plate maple syrup filter, that looks substantially similar to the $7000+ device from the famous supplier. Mine, from Smokey Lake Maple is, according to Smokey Lake, the only “maple syrup filter” made of Stainless Steel here in the USA, which, with 20 plates and a pump sells for $2600, not $7000). anyway, I filtered this and left it overnight in my conical stainless steel “fermenter”, which is a cool 14 gallon conical container with spigot, lid etc. and the next morning it had separated nicely and I drained the water, and then redistilled the now remediated product, which I dissolved in my favorite solvent (that everybody else hates), and I dried it with anhydrous Sodium Sulfate, put it in my short path which I backflushed with noble gas, removed the solvent, distilled it with care and repeated the process, with larger batches in my larger flasks. The long and short of it is that I returned the first L of finished product to my clients who had their lab of choice test it and it did indeed pass. There is obviously more detail. But I doubt that I can tell anybody anything that is not already published here by others who seem to have infinite patience with helping others! AND THANK YOU Future4200, your forum here is THE BEST SOURCE OF CREDIBLE AND THOROUGH AND TRUE AND CORRECT INFORMATION AVAILABLE FREE, OR FOR A PRICE, THAT I AM AWARE OF!!! KEEP IT GOING, YOU ARE RAISING THE QUALITY BY IMPROVING THE KNOWLEDGE LEVEL OF ALL WHO COME HERE TO READ AND ABSORB!

This is great news, and I am certain that you are helping a lot of people with this info., as well as me! Thank you!!! ![]() I have another dirty batch that I will be starting shortly, so when they drop this off I will follow your procedure and post the results as soon as I finish, and after I test it at the University! Thank you! Last time my starting level of Myclobutanil was .253 Do you mind my asking what your starting numbers were?

I have another dirty batch that I will be starting shortly, so when they drop this off I will follow your procedure and post the results as soon as I finish, and after I test it at the University! Thank you! Last time my starting level of Myclobutanil was .253 Do you mind my asking what your starting numbers were?

.168. But water is cheap. Throw as much at it as time allows. I would have used more but 10 gals is what I had. It started off cloudy/yellowish and was clear by the 5th wash but i wouldn’t take that as any indicator of complete extraction. Don’t fear the emulsion! I’ll all come out in the wash as they say!

Thank you again Cdplchem! I owe you one! ![]()

We’re all here for each other. By the way if Pesticide Properties Data Base (PPDB) from The University of Hertfordshire it is a HUGE wealth of info. I’m pretty confident that this process would work on any pesticide that has a reasonable (moderate) water solubility (say above 100 mg/l). Acephate, carbofuran…

I’ve been using a wine plate filter for years. cost 2100 with pump. I died of laughter when I saw the pig filter for sale, its literally the exact same as smokey lake but with green tax applied

Cdplchem, I do think a great deal of this forum, and those who contribute, and I truly believe that this forum is doing a LOT to bring new folks to chemistry for hobby and profit and health, and there is a pleasant family atmosphere, as much as that is possible in a forum! Thank you again, BTW!

Green Tax! I love this euphemism! And it is spot on! I see the most ridiculous prices for everyday items and services, or at least everyday to those of us who have an interest in chemistry… I hope to contribute to this forum, if and when I have truly useful information to share… Beginning now perhaps, with the observation that by purchasing used from ThE Bay and purchasing carefully from Amazon, and choosing a simple jacketed flask and a used column and, and some cheap pumps and a system to control them and a couple of stainless stock pots, & etc., which can all be had for ~$500, will yield a truly effective cannabis extracting and refining system, provided one has the patience to learn and figure out how to repurpose equipment from other hobbies and tech pursuits. But with these things, one can be cobble together a system for cannabis extraction and distillation etc., such that it can put out quite a bit of volume of high quality materials, as well as handle most every type of chemistry that is necessary to achieve real success in the hemp/cannabis hobbies and businesses. A good vacuum system is necessary too, and it is a bit more demanding, both financially and in terms of proper use and safety, so the $500 figure is about 1/2 way there. But with a ~$500 system + a real vacuum system, combined with creativity and a willingness to study and with an open mind, an enthusiast who is new to chemistry can enjoy excellent results and success in the hobby and or business of cannabis chemistry. And for instance, when it comes to distilling, with that ~$500 system, it is more than possible to enjoy results that are as good as the heavy bankroll types get from their wiped film systems! But for those who choose the $500 system + a few extras and a vacuum system, so very much more chemistry can be done, past distillation! The benefit of versatility based on a variety of proven “old school” equipment, such as a jacketed boiling flask and an $8 immersion heater from Bed Bath and Beyond, and a $20 point and shoot thermometer and a couple of cheap bronze gear oil pumps, and some stainless soup pots, and a couple of used condensers and some copper Choir Boy scrubbing pads and some cheap used condensers and so on, allows for a terrific variety of interesting and profitable chemistry beyond cannabis to be done, and done well, as well of course as pursuits into hemp chemistry… But this requires one more rare ingredient that is almost impossible to find anywhere except right here - encouragement and help from folks like the good contributors in this forum… God Bless them, one and all! They are doing more to create a new generation of chemists than just about anything or anyone else that I am aware of! Seriously, this forum is unique and it is providing a path for those new to chemistry to enjoy some successes with it, which is the thing that will keep them going with their new hobby and business. And who knows what cool inventions and processes THEY will develop along the way!?! Keep on Future4200, you are the BEST!!! ![]()

Can u elaborate? Pentane and acetic acid for chlorfenapyr? Just using acid to degrade it?

Anyone dealt with Chlordane? It’s not water soluble, and it boils around 174C which makes this tricky for us. We’re only 0.4ppm (0.1ppm is actionable levels) in the distillate. How the heck it ended up there is a mystery.

Comes from the plant material. It’s below detectable levels until concentrated. Used back in the day all over california for termite control and now soil grown cannabis has trace amounts in it decades later. I wrote an SOP for a client that should easily remove chlordane with pretty simple chromatography. Chlorine molecules on the entire outside of the chlordane molecule should be well attracted to silica.

Hello Chemphox, I’m back with an update and unfortunately it’s not good news. The process I described earlier seems now not to have worked. The product that I remediated (distillate) did indeed come back ND; so I redistilled it and sent a sample for further testing (same lab). Lost about 10% and the shit was golden yellow, just beautiful! It came back dirty. Not just dirty but nearly three times higher than the original distillate (.167 to .376!). I cried bloody murder! No way, test it again. So they did. Got results back today. Not only is it dirty but it’s even HIGHER @ .426! I’m not only not remediating myclo I’m spontaneously creating it!!! I F*^#*^ING hate pesticides!