229 to 231 has been our go to for temps. Hitting 235 puts a quahetus on our production line. If we ever hit 240, it’d go directly into the waste container.

YES! this is what I hypothesized / suggested for scaling pectin at my facility! yet to be implemented, but I certainly feel validated right now ![]()

is this done batch-wise in the small mixing vessel or continuously? sorry if that’s a dumb question.

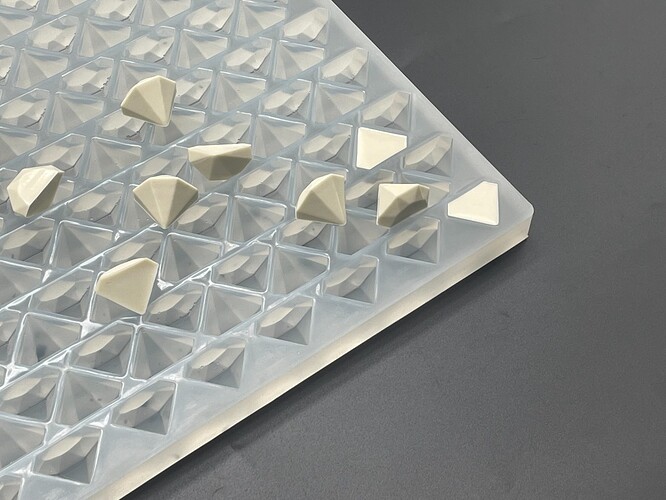

It is done batch-wire in small mixing vessel (50L one) then transfer slowly into the hopper. See below for a set up in one of my client space.

@jimmytian8 got to see one of your setups in person the other day. Looks really good can’t wait to see her run

This is cool, i always wanted to incorporate a homogenizing transfer pump to take advantage of hydrocolloid shear thinning and extend the depositing time. Bigger hopper you can fill to the top helps mitigate operator error when you’re working with 2+ colors or consistencies. Nothing worse than tossing a couple bubbly molds mid run because one of your hoppers ran dry

Using a thermocouple logger and a k type 18” probe works even better. You can wire one into a PID and use it to control your cooking equipment so you can dial in your temp ramp if you’re doing different confections on the same line.

@Kingofthekush420 Interested in ordering compliant d9 gummies. Please PM, I am unable too

how is d9 compliant when it is over .3 by volume? hemp derived or not did people forget about that part or just not give a fuck?

Over .3 by weight and it wouldn’t be…

We have D9 THC-O and other cannabinoids that are stronger now days. The .3 is old school news/ irrelevant now, in edibles!

Just saying!

You should be looking for ND D9 THC.

wow your profile pic is cool, that a nice looking gummy!