I tinkered here and there for a few months working on a 5g packer until I realized that no one in their right mind would want a 5g cigar (Makes sense why these people got fired) and I shelved it. They’re also big enough that a funnel works well enough to pack the 10 you need to make for the month lol.

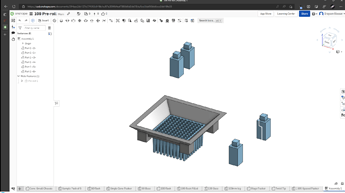

So I had the 109mm 1g standard pre-roll cone. I did a lot of thinking (and I hadn’t had any requests so there wasn’t much impetus) for me to make it that quickly. Becuase papers are much more delicate than the blunt tubes, I decided to go with a tapered cone design to support the cones as much as possible. I went through a lot of iterations before I was actually happy. Here is what a 5 packer of the thing looked like.

June 2022

It worked ok, but I there’s kind of an issue with this style of design. All of the pre–roll filters are not perfectly circular, which makes this kind of tricky because while the diameter is about 6mm, I had to print it at 8mm to account for print bleed and the eccentricity of the tips. I found the 8mm style was better so I went for it and made a 50 packer with a small chassis/resting plate to go with it.

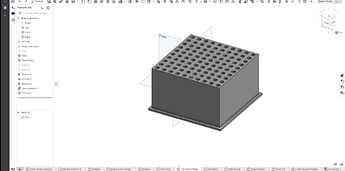

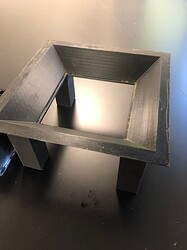

Here’s the 50 packer.

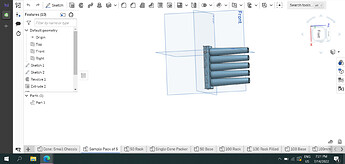

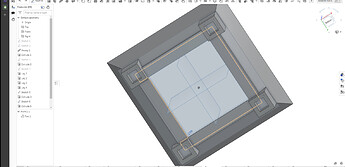

The frame for the thing, and while it looks cool. Anyone see an issue with it? The sticky little legs! It worked great, but after about 6 slams on the table, all 4 legs broke. Fortunately, the pre-rolls I was able to get out of this, were really nicely packed!

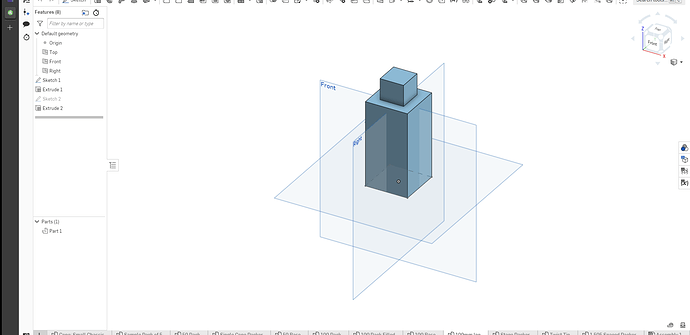

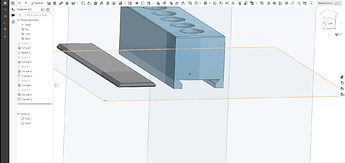

Because the packing worked well, I decided to scale it up to a 1st draft 100 rack. The tweaks I made were increasing the size of the legs from 0.5gm to 4cm, making more of a funnel shape and reducing the filter hole size a bit to make it settle better.

I also decided to try and make this one a bit more modular, so the chassis (now called the base) has removable legs and the frame slide out so it could be swapped for smaller/different size legs. I also decided to fill the frame design. It didn’t add that much print time and made it look a bit better and limited possible cleaning issues with the numerous cavities between the cones.

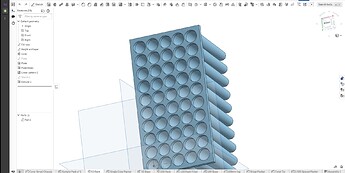

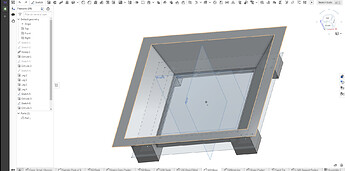

The chassis (2 day print time. Woof)

The base (top and bottom) with a nice open funnel, 4cm legs and a little lip for the edges of the frame to sit on

The leg design. I printed 4.

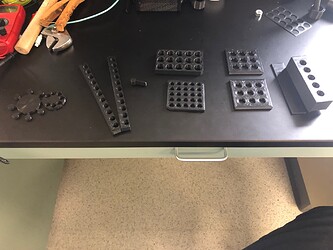

Resulting Print after ~1 week

So this was a disappointing batch. It looks like there were some issues with filament getting snagged as I got to higher layers, because there’s this wierd cracking that is going on towards the base. I tried to super-glue it together, but it didn’t help and kind of dissolve into the plastic. (I printed the top face down). I wasn’t really that happy with the surface finish on it, my BL touch (sensor for leveling the bed) was getting off because the clamp had broken so it started to mess up and didn’t leave the smoothest finish.

The frame came out really nicely barring a weird defect (again from my BLtouch being off). The legs also looked pretty good but fit too loosely so I had to tape them into place; had to google tolerances for pin-mating features.

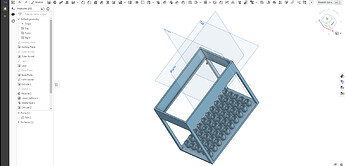

The thing I really wanted to see was how did it slot into place. This was the nice thing about this design, it fit really well and the plate of the frame fit perfectly into the base.

So we gave it a try, and at first it was a fucking nightmare. I wasn’t getting pre-rolls that packed near the crutch, some were getting crinkled, and I was only able to do about 100/person*hr (really shitty). The main issue was the filters tips weren’t touching the table and thus wasn’t packing. We tried literally every packing technique we could. Packing little by little, and it really was still kinda shitty. We tried pushing them down, but it led to the issues earlier stated.

I thought I had dimensioned this thing to be 109mm perfectly, but apparently some fuckery was afoot and after reducing the leg length by 6mm and that fixed everything. I just cut the legs down a few mm with a Dremel because it was such a pain, but we diagnosed it with a few pieces of cardboard stapled together to sit under the filter tips. Now the pre rolls were able to rest against the table. When banging it against the table, it was able to hit the filter tips perfectly so they wouldn’t fly up out of the frame, but they would hit the table and pack well. Then a final pack and twist.

So with all that here are the parts for the most recent iteration.

Frame: 100 Rack Filled (1).stl (4.2 MB)

Base: 100 Base (1).stl (9.8 KB)

Leg (dimensioned properly): 109mm leg (1).stl (1.4 KB)

Edit: The legs are VEEERRY snug, you may need to ‘deburr’ the edges of the pegs because 3d printers tend to ooze a bit extra at right angles, its not made to be removable, but I’m not planning on removing them.

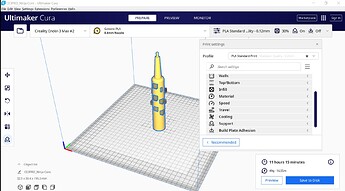

Slicer settings (CURA) for ender 3 max with BL Touch, bowden stock extruder, and glass bed. PLA ($19 from amazon).

I WILL PROBABLY NOT POST THESE AGAIN BECAUSE THERES ALOT, I’LL MENTION ANY DEVIATIONS FROM THIS IF I MAKE THEM.

Quality (can change)

Layer Height: 0.2mm

Initial Layer Height: 0.2mm

Line Width: 0.4mm

Walls

Wall thickness: 0.8mm

Wall line count: 2

Outer wall wipe distance: 0.5mm (super important to prevent stringing)

Horizontal expansion: 0mm (0.2mm is a good idea for the circles if your designs aren’t dimensioned to account for this)

Top/Bottom

Top/Bottom Thickness: 0.8mm

Top Thickness 0.8mm

Top Layers:4

Bottom Thickness: 0.8 mm

Bottom Layers: 4

Top/bottom pattern: Concentric

Bottom Pattern Initial Layer: Concentric

Enable Ironing: True

Iron Only Highest Layer: False

Ironing Pattern: Concentric (Do whatever you think is cool)

Monotonic Ironing Order: True

Infill

Infill density: (Varies) 10-15%

Infill pattern: Gyroid (super sturdy and cuts down on infill material)

Infill Overlap Percentage: 20% (Limits visual artefacts from normal 30%)

Material (PLA)

Printing Temperature: 200C

Printing Temperature Initial Layer: 205C

Build Plate Temperature: 60C

Speed (Slower walls and jerk improve print quality)

Print Speed: 80mm/s

Infill Speed: 80mm/s

Wall Speed: 40mm/s (limits blobs and zits)

Enable Jerk Control: True

Print Jerk: 8.00mm/s^2

Initial Jerk Layer: 2:0 mm/s

Initial Layer Print Jerk: 2.0 mm/s

Initial Layer Travel Jerk: 8.0 mm/s

Travel

Enable Retraction: True

Retraction Distance: 6.5mm

Retraction Speed: 25mm/s

Combing Mode: Wit Infill (Crazy important for preventing stringing)

Avoid printed Parts When Travelling: True

Avoid Supports when Travelling: True (prevents nozzle from knocking supports over)

Z hop when retracted: False (garbage setting, you will string like crazy)

Cooling

Enable Print Cooling: True

Fan speed: 100%

Regular fan Speed: 100%

Maximum fan Speed: 100%

Initial fan speed: 0%

Regular Fans speed at height: 0.6mm

Regular fan speed at layer: 4

Support (My settings aren’t as dialed in)

Overhang angle: 50deg

Support Pattern: Zig Zag

Build Plate Adhesion (Note I have auto bed leveling and it is pretty much down to the 10micron precise. Getting a good first layer is pinnacle so figure your own thing out).

Adhesion Type: Skirt

Skirt Line Count: 3

Skirt Distance: 10 mm

Mesh Fixes (Needed to limit blobs again because circles)

Maximum Resolution: 0.25mm

Maximum Travel Resolution: 0.25mm

Maximum deviation: 0.025mm