I just hate peristaltics because the pope from B and W has one and it’s a nightmare lol

Yeah well they have a way of just making everything be a piece of crap. Sad to say I think the chinese ones are better quality!

Deleted

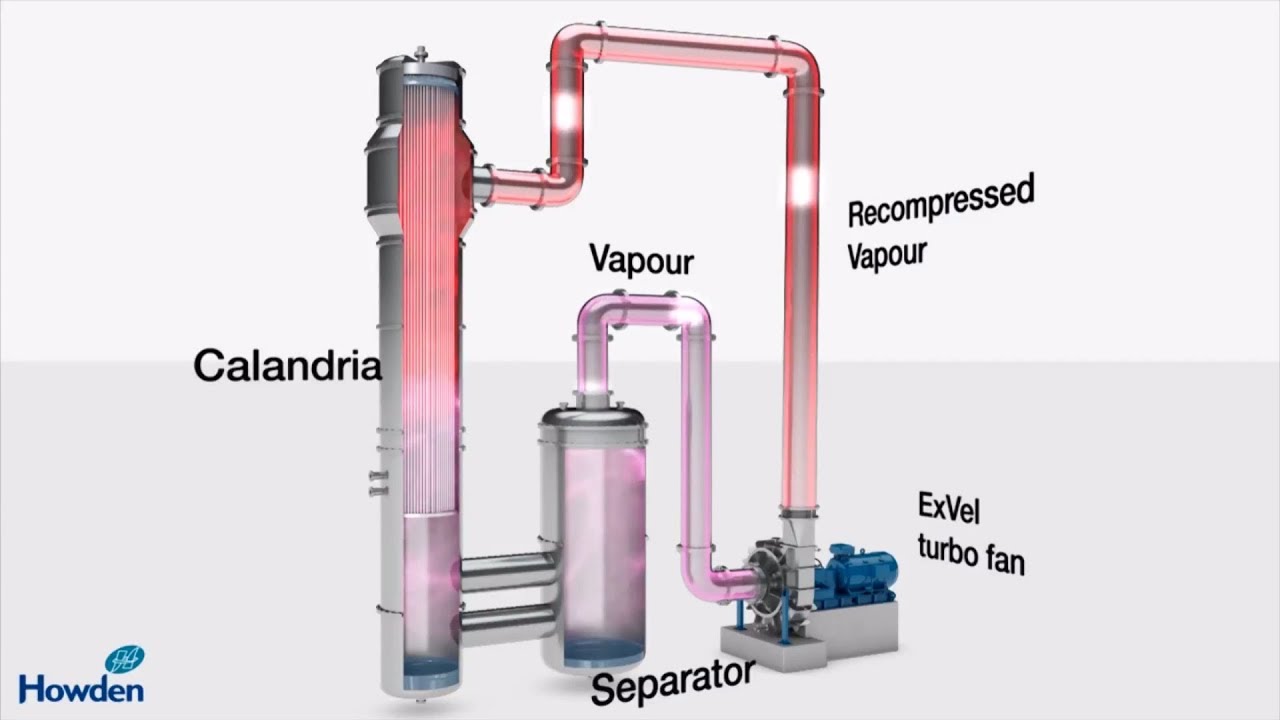

Minus the vapor recompression

And read this thread for some solid info and has some mini ffe ideas Utilizing a Hot and Cold Dephlegmator cls still

That’s brilliant. I bet that turbine pump costs a bit more than an on-demand water heater though lol. I bet you could do the same with a regular gas booster pump though (although the inefficiency of running an air driven one might make it a wash)

That’s the video that actually explained how a ffe works and then I went from there. I’m gonna have one built by the end of the year. Again minus the vapor recompression on my end.

I would imagine that specific turbine massive FFE you see in other industries, but that’s a great idea.

It seems to utilize the same idea as a horizontal FFE by recycling energy produced elsewhere in the process. Now someone just need to figure out how to scale this down a little for solvent recovery

And make it C1D1

A much easier way to do this is to use plate heat exchanger to preheat the crude for evaporation with the already evaporated ethanol vapor

This is the design my FFE will utilize

I’ll upload pics once I have it on the frame

Damn broski, youve been working on that FFE for like 2 years now it feels like…

I’ve stopped several times

Now I actually need one to go with my membrane skid so

Hey man, could you send me some info on what you decided to go with for gear pump/vfd? We are trying to source one for our falling film currently.

vapor compression distillation (VCD)

A further explanation of mechanical vapor recompression

This was a beautiful design…

How much flow (LPM?) of well water did you have?

Does anyone know if 20L per minute at 0C would be enough to make decent recovery?

If you add baffles across your condenser tubes going from left to right and then alternating right to left and back around the other direction forcing your thermal exchange fluid in a zigzag direction going from one end of your condenser shell to the other and in doing so it will make your condenser immensely more efficient.

V1 didn’t have baffles. All of the later versions they produced and sold did.

how did you like the beaker and wrench solvent pump? and what kind of pump are you using for the crude?

Ok so I am finally ready for a diy falling film

Any new designs parts nozzles that folks wan t to share ?

@Thetetraguy any tip s you can share

Thx

As far as nozzles goes, i stopped worrying about it so much and just stuffed some SS wool above the first heat exchanger.

Use a circulating propane heater for the main heating (unless uve got stupid amount of cheap electricity) that heater probably wont get hot enough, so i used a simple Tee triclamp/heating element setup in the water line after the outlet from the first heat exchanger to boost the heat up a bit.

My first tower is split between 3 heat exhangers and im kinda glad its like that because it loses roughly 10F between each Heat Exchanger, so the little booster is able to get the fluid back to its initial temp. If u had one long heat exchanger, there would be hard to apply heat half way thru the fluid cycle in the tube.

A peralstaltic pump is sufficient to deposit the crude from the collection vessel. I pump mine directly into a reactor now for decarbing.

Running the incoming tincture through the first H.E. jacket, on the cooling tower side, has helped tremendously. I just make sure to drain it and flush with fresh ethanol after every run. Mine holds roughly 1 gallon in the jacket, so after the drain, i flush with 3-5 gallons, by that time the ethanol is trickling down clear.