Nice pitty the damn deplegmators are so pricy got to find me a china producer

nah, it just needs a little cleaning

now you get it ![]()

I need on that runes on butane !!

But small 50 kg an hour max

If ever you see one let me know ![]()

Here is a small system I put together with usalab parts and some glacier tank parts. System has a few issues but does some serious evaporation on a budget.

The 4 bus outlet is no longer there. For all you safety nazi’s lol. This system was set up onsite at my buddies hemp farm. Works well for his use.

System runs on recirculating heated water from a propane fired burner and cold ground water

Total cost around 8k could be cheaper if you source parts wisely.

Recovery rate is about 10gph

Things that would really increase speed…

Preheating suspension

Sourcing a spray nozzle for the feed

Note that the issue of even tube distribution can be corrected with stuffing some stainless wire/thread down about a foot of each tube. We also put glass beads about 2inches above the condensor. Not the nicest system but the fastest solvent recovery I’ve gotten for under 8k. We can get good resin consistency with a 2nd pass of the material. About 30min. A bunch of the parts I already had from other projects like the 4in sight glasses and 3in spool parts.

Cool things about the set up

Filter plate with proof up beads keeps etoh proper

You can place filter paper a few points within the system to catch any missed particulates ( hopefully you did a good job during filtration. But this helps just in case.)

With viton gaskets can be used with multiple solvents

Positive pressure on keg sends clean etoh anywhere you need it after evaporation.

Great thread…just wanted to contribute

Feel free to ask questions about parts or give tips

Usalab gives the glg discount also ![]()

How are the four hoses hooked up on the condenser side?

What’s the the four bus outlet?

Do you mean you get good resin from second pass running through the ffe or distillate run?

The first pass still has a decent amount of ethanol. From 10/1 down to about 1/1. That’s running fast a little over 10gph. Toy have 2 options. Slow the feed rate to do a one and done, or power through and 2nd pass for a good thick crude consistency.

hi, which kind electric heater could suitable for this FFE? who have pictures?

and how the body contact with heater, chiller, pump?who could help me?

U running hexane or methanol? U gonna be operating under vac or at atm?

80 GPH ethanol / methanol it will also be compatible with hexane and heptane.

Tbh I was gonna run under vac but after talking with @downtheterphole for hours and hours about ffe design (he works with Yellowstone), I think I’m gonna run her at atmosphere. Mainly for condensing purposes.

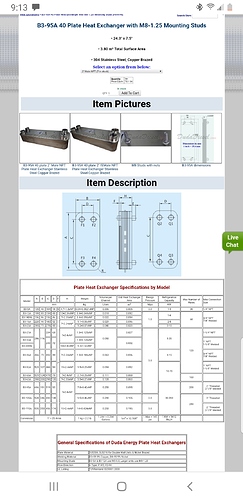

I’m going to use a bunch of huge plate heat exchangers to preheat the incoming crude / cool the hot vapor so you shouldnt need much cooling.

Gas is cheaper than electricity so if you used a propane water heater it would be even cheaper than an electric one. This is another reason why I am not going to run vacuum, it would require me to have more chilling power which is more expensive IMO than heating power.

Plate exchangers for pre-heating the tincture? I was under the assumption that only clean solvent/solvent vapor was appropriate to use with plate exchangers?

Edit: How significantly does running at atmosphere affect how much surface area/heat input is required for vaporization vs. running under vac? Sounds like it would also reduce cost of pumps since the pumps wouldn’t have to work against vacuum.

Delta separations does it with no problem, you need to filter down to 1 micron first

They also get 30% more efficiency with just 1 plate heat exchanger that’s small

I’m using 3 that are 4 times the size lol

vac just makes it easier to reach boil temperature and harder to reach condense temperature.

it’s exciting to finally see some of these generic serpent evaporator units come together

What about throttling down the feed after the heated jacket?

Or running a -30c chiller on the condensing side.

The one I designed are using 6” shotgun jacketed spools to increase surface area so I can vac it down. We go from 6” to 3” back to 6” to see how far of a vac we can get down to increase speed flow.

Also, running a 100g jacketed solvent tank with a feed line valve for full control of the dip tube and preheat the tincture.

Love designing shit😁